Aluminum alloy broadly used in the die casting sectors of aerospace, automotive, and construction for their light weight and great strength-to-weight ratio.

Among these, the 7xxx series (Al-Zn-Mg-Cu) alloys are known to be very strong and indeed they are the best among all aluminum alloys.

A detailed overview of the highest strength aluminum alloys, their properties, and applications is shared in the content below.

Characteristics of various aluminum alloy materials

Aluminum alloys have different ratios to meet the product needs of different fields such as the automotive industry, home improvement industry, aerospace, and municipal engineering. Below we list the differences for you.

- 7xxx Series Aluminum Alloys

- Ultra-High Strength Aluminum Alloy

- Factors Contributing to High Strength

- Applications of High-Strength Aluminum Alloy

- Challenges and Future Developments

7xxx Series Aluminum Alloys

The 7xxx series, particularly Al-Zn-Mg-Cu alloys, are renowned for their ultra-high strength. These alloys achieve their strength through a combination of alloying elements (zinc, magnesium, and copper) and advanced heat treatment processes.

- Strength: The ultimate tensile strength (UTS) of commercial 7xxx alloys typically ranges from 500 to 700 MPa, with some advanced variants exceeding 900 MPa 511.

- Examples:

- 7075-T6: A widely used alloy with a UTS of 572 MPa 3.

- 7150-T77: A second-generation alloy with a UTS of over 700 MPa, offering a balance of high strength and corrosion resistance 13.

- Al-MS78: An advanced powder-processed alloy with a strength 40% higher than 7075, reaching up to 800 MPa 11.

Ultra-High Strength Aluminum Alloy

Recent advancements in material science have led to the development of ultra-high strength aluminum alloys with strengths exceeding 1,000 MPa. These alloys are often produced using advanced processing techniques such as powder metallurgy and hypersonic liquid atomization.

- Al-WQ68: A wrought-processed alloy with a UTS of over 700 MPa, suitable for high-thickness applications 11.

- A-1500: An experimental alloy with a UTS of over 1,200 MPa and 5% elongation, achieved through a novel hypersonic liquid atomization process 11.

Factors Contributing to High Strength

- Alloying Elements: Zinc, magnesium, and copper are key elements that enhance strength through solid solution strengthening and precipitation hardening 510.

- Heat Treatment: Multi-stage solution aging and T6 tempering are critical for achieving optimal strength and toughness 10.

- Microstructure Control: Advanced processing techniques, such as severe plastic deformation (SPD) and rapid solidification, refine grain structures and improve mechanical properties 5.

Applications of High-Strength Aluminum Alloy

- Aerospace: Used in aircraft frames, landing gear, and structural components due to their high strength-to-weight ratio 1014.

- Automotive: Ideal for lightweight, high-performance parts such as suspension systems and chassis components 11.

- Industrial Machinery: Suitable for high-stress applications like fasteners and structural parts 11.

Challenges and Future Developments

- Corrosion Susceptibility: High zinc and magnesium content can increase susceptibility to localized corrosion, necessitating protective coatings or alloy modifications 5.

- Cost and Processing: Advanced alloys often require expensive and complex processing techniques, limiting their widespread use 11.

- Machine Learning: Researchers are using machine learning to optimize alloy compositions and processing routes, aiming to develop cost-effective, high-performance alloys 5.

More to tell

The 7xxx series aluminum alloys, particularly 7150-T77 and Al-MS78, currently represent the highest strength aluminum alloys, with strengths exceeding 700 MPa. Advanced variants like A-1500 push the boundaries further, achieving strengths over 1,200 MPa. These alloys are indispensable in industries requiring lightweight, high-strength materials, and ongoing research promises even greater advancements in the future. For more details, refer to sources like Nature and AMT Advanced Materials 511.

Different grades of aluminum and their applications

Aluminium alloy grades and their corresponding elements are as follows.We can use die casting machines to produce and process finished products and parts for various industries.:

- 1000 series: Contains at least 99% aluminium

- 2000 series: Contains copper

- 3000 series: Contains manganese

- 4000 series: Contains silicon

- 5000 series: Contains magnesium

- 6000 series: Contains magnesium-silicon alloys

- 7000 series: Contains zinc

Each aluminium alloy series possesses distinct advantages suited to different application domains. Let us examine the various aluminium alloy grades and their respective uses.

1000 Series Aluminium Alloys

1000 series aluminium alloys contain 99% aluminium with no significant alloying elements. They exhibit exceptional corrosion resistance alongside outstanding electrical and thermal conductivity. However, their strength is inferior to other aluminium alloys.

Being almost entirely composed of aluminium, the 1000 series is relatively soft with excellent ductility. It is most commonly using where an alloy needs to be machined into diverse products, such as chemical equipment, instrument dials, railway tankers, and electrical conductors. The most prevalent grade within the 1000 series is 1100 aluminium alloy, which possesses the highest mechanical strength.

2000 Series Aluminium Alloys

The 2000 series aluminium alloys utilise copper as the primary alloying element, enhancing the strength and hardness of the aluminium. However, welding these alloys presents challenges due to their susceptibility to shrinkage cracks during the hardening process. 2000 series alloys are frequently using in truck wheels and suspension systems, as well as within the aerospace industry.

Aluminium alloy 2024 stands as one of the most recognised grades within the 2000 series. It exhibits a high strength-to-weight ratio and excellent corrosion resistance.

3000 Series Aluminium Alloys

Manganese is the primary alloying element in 3000 series aluminium alloys. Manganese imparts higher strength to the alloy, enabling it to maintain stability across a broad temperature range. 3000 series alloys also possess good formability and ductility, with moderate strength and corrosion resistance.

Aluminium alloy 3003 is the most commonly used alloy within the 3000 series. It is a versatile general-purpose aluminium alloy frequently employed in automotive and electronic applications. Although it is also commonly used in cookware, such as cutlery and pot lids, its insufficient heat resistance prevents it from withstanding oven temperatures.

4000 Series Aluminium Alloys

4000 series aluminium alloys are adding silicon. These alloys typically also contain small amounts of copper and magnesium. The addition of silicon lowers the melting point of the aluminium, making 4000 series alloys highly suitable for welding. They are frequently showing in the construction sector. Examples of 4000 series alloys include:

- Aluminium Alloy 4006

- Aluminium Alloy 4015

- Aluminium Alloy 4032

- Aluminium Alloy 4043

5000 Series Aluminium Alloys

5000 series aluminium alloys contain magnesium. Like 3000 series alloys, they cannot be heat-treated and must be cold-worked. They offer medium to high strength, good weldability, and corrosion resistance. 5000 series aluminium alloys are commonly used in household appliances, automotive components, and structural elements such as beams and tubes.

Aluminium alloy 5052 possesses excellent thermal conductivity, making it widely employed in heat exchangers and cookware. Other frequently used alloys within the 5000 series include aluminium alloy 5083 and aluminium alloy 5005.

6000 Series Aluminium Alloys

The 6000 series aluminium alloys incorporate silicon and magnesium, imparting moderate strength, good formability, weldability, and corrosion resistance. These alloys can be further strengthened through heat treatment, making them ideal for structural and architectural applications.

Two common grades within the 6000 series are 6061 aluminium alloy and 6063 aluminium alloy:

6061 Aluminium Alloy: Often termed the ‘workhorse alloy’ due to its versatility and high strength, 6061 offers exceptional strength, corrosion resistance, and high-temperature weldability. It is suitable for products subjected to high wear, such as furniture with exposed edges.

6063 Aluminium Alloy: Although 6063 aluminium alloy is less strong than 6061, it remains highly practical for residential applications. It is extensively using in the manufacture of window frames, doors, railings, and decorative structures. Furthermore, 6063 aluminium alloy exhibits excellent corrosion resistance.

7000 Series Aluminium Alloys

Zinc is the alloying element in the 7000 series aluminium alloys. These alloys rank among the strongest and most durable aluminium alloys available. This series exhibits exceptional corrosion resistance and can be heat-treated, though it is generally non-weldable. 7000 series alloys are frequently employed in aircraft fuselage structures, mobile equipment, and components subjected to high stresses.

7075 aluminium alloy is an exceptionally high-strength aluminium alloy. It can withstand prolonged high stresses, exhibiting even greater strength than 6061 aluminium alloy. Beyond aerospace applications, 7075 aluminium alloy is also employed in bicycle components and competitive sports equipment.

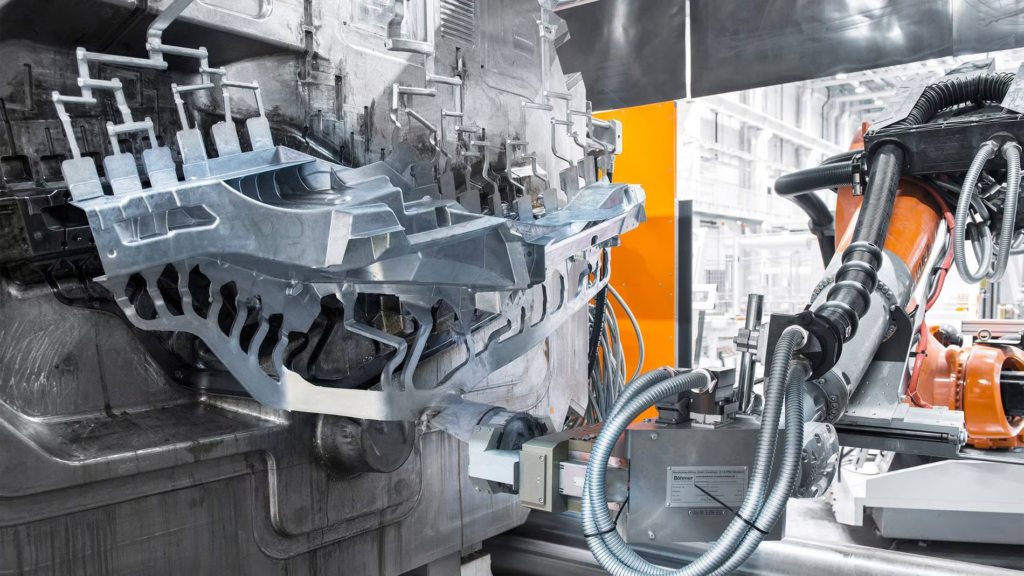

Aluminum Alloys for Die Casting

Aluminum alloys are the cornerstone of die casting due to their lightweight, strength, and versatility. Below is an in-depth overview of the most commonly used aluminum alloys in die casting, their properties, and industrial applications, synthesized from authoritative sources.

- Common Aluminum Die Casting Alloys

- Comparative Analysis of Key Alloys

- Factors Influencing Alloy Selection

- Challenges in Aluminum Die Casting

- Applications Across Industries

Common Aluminum Die Casting Alloys

The selection of aluminum alloy depends on factors like mechanical strength, corrosion resistance, thermal conductivity, and cost.

A380 115

- Properties:

- Excellent fluidity for intricate shapes and thin walls.

- High pressure tightness and good machinability.

- Moderate corrosion resistance and thermal conductivity (96.2 W/m·K).

- Applications: Automotive engine blocks, transmission housings, and consumer electronics.

- Limitations: Susceptible to hot cracking and porosity; higher cost compared to some alloys.

A356 13

- Properties:

- High strength and ductility, ideal for heavy-load applications.

- Good corrosion resistance and castability.

- Higher thermal conductivity (110 W/m·K) than A380.

- Applications: Aerospace components, structural parts, and automotive suspension systems.

- Limitations: Darkens during anodizing; reduced electrical conductivity after aging.

A413 115

- Properties:

- Superior pressure tightness and leak resistance.

- High strength-to-weight ratio and hot cracking resistance.

- Applications: Hydraulic components, heat sinks, and parts requiring leak-proof performance.

- Limitations: Lower tensile strength than A380; higher cost than A383.

A360 115

- Properties:

- Excellent ductility and corrosion resistance.

- Superior pressure tightness and dimensional stability.

- Applications: Automotive and aerospace parts requiring high mechanical strength at elevated temperatures.

- Limitations: Difficult to cast and prone to surface scratches.

B390 1

- Properties:

- High wear resistance and rigidity.

- Lower melting point and good recyclability.

- Applications: Pistons, brake systems, and engine components.

- Limitations: Poor corrosion resistance; aggressive on die-casting tools.

Comparative Analysis of Key Alloys

| Property | A380 | A356 | A413 | A360 | B390 |

|---|---|---|---|---|---|

| Density (g/cm³) | 2.71 | 2.68 | 2.66 | 2.63 | 2.80 |

| Thermal Conductivity (W/m·K) | 96.2 | 110 | 35 | 30 | 22 |

| Corrosion Resistance | Moderate | High | Moderate | High | Low |

| Typical Use | Engine blocks | Aerospace | Hydraulics | High-temp parts | Wear-resistant parts |

Factors Influencing Alloy Selection

- Strength Requirements: A356 and A413 are preferred for high-stress applications like aerospace and automotive frames 13.

- Corrosion Resistance: A360 and A356 excel in environments with moisture or salt exposure 115.

- Thermal Conductivity: A356 is ideal for heat sinks and electronics due to its high thermal conductivity 115.

- Cost-Efficiency: A380 and A383 balance cost and performance for high-volume production 1.

Challenges in Aluminum Die Casting

- Porosity: Caused by trapped air during injection. Mitigated through vacuum die casting or optimized venting 15.

- Hot Cracking: Common in alloys like A380; reduced by using ductile alloys like A360 1.

- Surface Defects: Flash and sink marks can be minimized with precise temperature control and die maintenance 15.

Applications Across Industries

- Automotive: Engine blocks (A380), transmission housings (A413), and suspension parts (A356)

- Aerospace: Lightweight structural components (A356) and heat-resistant parts (A360)

- Electronics: Heat sinks (A356) and device housings (A360)

- Consumer Goods: Durable appliances and sports equipment (B390)

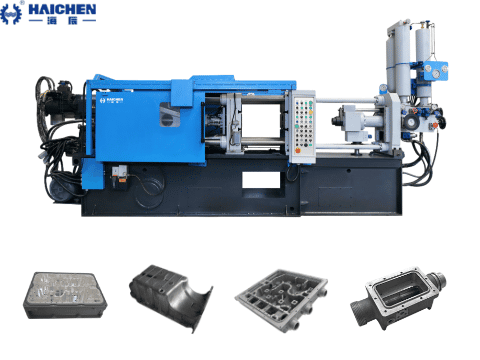

Application of aluminum die casting project in Haichen

Haichen is a Chinese aluminum alloy die casting machine manufacturer with nearly 20 years of history. We produce high pressure cold chamber die casting machines and hot chamber die casting machines. They are durable and high precision. Haichen also produces die casting machine auxiliary equipment. Such as conveyors, vacuum machines, mold temperature controllers, industrial robots, sprayers, etc.

As a leading manufacturer of cold-chamber die-casting machines, Haichen excels in the production of aluminium cookware through advanced technology and extensive industry expertise. Below is a detailed overview of its equipment and processes:

- Core Technology and Equipment

- Production Process

Core Technology and Equipment

Cold-Chamber Die-Casting:

Injecting molten aluminium under high pressure (50.4–127.3 MPa) into moulds ensures products possess exceptional density, strength, and resistance to deformation.

Ideal for producing complex-shaped items such as pots, pans, and baking trays.

Machine Tonnage and Applications:

220–300 tonne models: Suitable for small cookware (e.g., sandwich pans, 700g–3kg).

580-tonne models: Produce large cookware with substantial wall thickness (pots, frying pans) for uniform heat distribution and durability.

Control System:

Siemens PLC automation system featuring a multilingual interface (Chinese, English, Russian).

Real-time injection curve monitoring enables precise moulding.

Production Process

Aluminium Cookware Production Line

Feel free to contact us for information on die casting machines in Mexico and Argentina~