Hot chamber die casting machines characteristics include high production efficiency, high precision and surface quality, high degree of automation and wide application areas.

Hot chamber die casting machines characteristics

A hot chamber die casting machine is specifically designed for casting metals with low melting points, such as zinc, magnesium, and lead alloys.

Applicable materials of hot chamber die casting machines characteristics

- Hot chamber die casting machines are mainly used for casting low melting point metals. It includes zinc, lead, tin and some magnesium alloys.

- These materials have low melting points and good fluidity. And they are suitable for rapid melting and injection into the mold in a hot chamber die casting machine.

Working Principle of hot chamber die casting machines characteristics

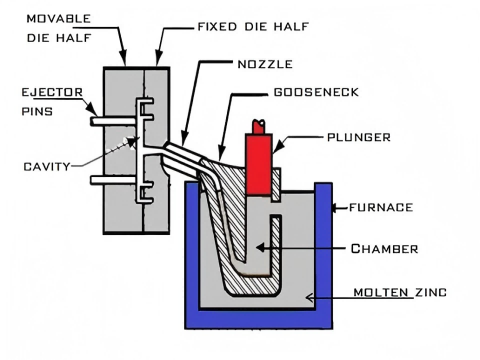

- The core components of a hot chamber die casting machine are the furnace and the injection system. The furnace heats the metal to a liquid state and then feeds the molten metal through a valve into the injection system.

- The injection system hydraulically or pneumatically actuates a piston that injects the molten metal into the mold cavity at high speed. This design allows the metal to cool and solidify quickly in the mold to form the part.

High production efficiency

- Hot chamber die casting machines have extremely high production efficiency, and can complete multiple cycles per minute (usually around 15). It makes them suitable for mass production of small, complex shaped parts.

- For example, some machines can produce at a rate of more than 100 cycles per minute.

High precision and surface quality

- Because the molten metal is in direct contact with the mold, hot chamber die casting machines are able to produce parts with high dimensional accuracy and good surface quality.

- In addition, because the metal flows well, the wall thickness of the part can be thinner while reducing porosity and defects.

Highly automation

- Modern hot chamber die casting machines are usually equipped with advanced control systems. Such as PLC control and non-contact sensors, which are capable of realizing highly automated operation and reducing manual intervention.

Low heat loss

- Because the molten metal is always in the closed channel, the heat loss of the hot chamber die casting machine is small. It helps to improve the efficiency of energy utilization.

Simple equipment structure

- The structure of hot chamber die casting machine is relatively simple and easy to operate and maintain.

- Its main components include furnace, injection system, mold and ejector mechanism.

Application fields

- Hot chamber die casting machines are widely used in automotive, aerospace, electronics, medical and other industries, mainly for the production of small, complex shaped parts, such as automotive parts, electronic components shell.

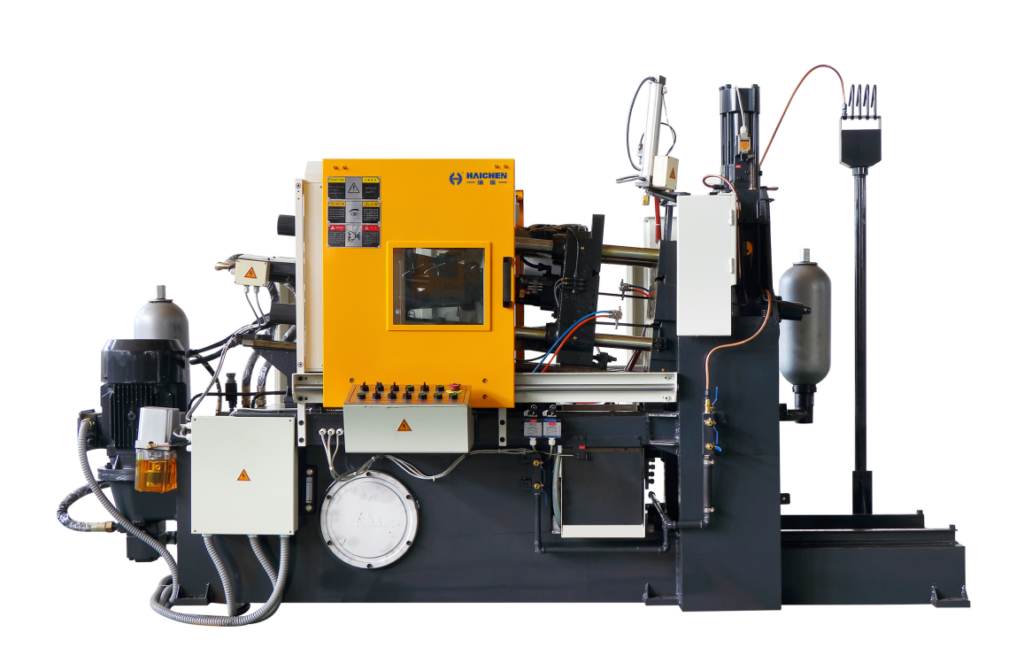

Haichen hot chamber die casting machines supplier

Haichen is a well-known manufacturer of die casting machines, including hot chamber die casting machines. Their machines are recognized for their reliability, advanced technology, and efficiency in producing high-quality die-cast parts.

Besides hot chamber die casting machines, we also supply cold chamber die casting machines and auxiliary equipments. Welcome to consult us.