The Cold Chamber Die Casting Process Steps include die preparation, metal melting, injection, cooling, ejection, and post-processing.

Cold chamber die casting is a common method for manufacturing precision metal parts, especially for processing high melting point metal materials such as aluminum, copper and brass.

The operation requires first pouring molten metal into an injection chamber at room temperature (hence the name “cold chamber”), and then using a high-pressure plunger to press the liquid metal into the mold.

The whole process involves many delicate steps, which can ensure that the final part is both durable and accurate in size. Next, let’s take a closer look at the operation of cold chamber die casting.

Introduction to Cold Chamber Die Casting

Cold chamber die casting is a process for manufacturing complex metal parts with high surface finish and precise dimensions. This process is specially designed for processing high melting point metals such as aluminum, magnesium and copper alloys. During operation, workers or robotic arms first pour molten metal into the injection chamber, and then the plunger pushes the metal into the mold at a high pressure of more than 10,000 pounds per square inch (about 70,000 kPa).

Key Characteristics:

- Separate cold chamber design

- High melting point metal adaptability

- Process cycle characteristics

Separate cold chamber design

The molten metal is transferred to an independent injection sleeve by manual or robotic arms, which is separated from the main body of the die casting machine and is not additionally heated. This design effectively isolates the thermal erosion of high-temperature metals on core components, significantly extending the life of the equipment.

High melting point metal adaptability

The process is designed for metals with a melting point of more than 600°C, especially for aluminum alloys (such as ADC12, A380) and copper alloys (such as brass). These materials are prone to equipment corrosion in hot chamber die casting, and the cold chamber design solves this problem through physical isolation.

Process cycle characteristics

Due to the need to transfer molten metal separately (manually or automatically), each production cycle takes an average of 15%-30% longer than hot chamber die casting. Temperature fluctuations during metal transfer also require more precise injection parameter control, further affecting overall efficiency.

Cold Chamber Die Casting Process Steps

The cold chamber die casting process is particularly suitable for processing metals with higher temperatures, such as aluminum and magnesium alloys. This process allows manufacturers to produce complex parts with precise dimensions and smooth surfaces.

- Die Preparation

- Metal Preparation

- Injection of Molten Metal

- Cooling and Solidification

- Ejection of the Part

- Post-Processing

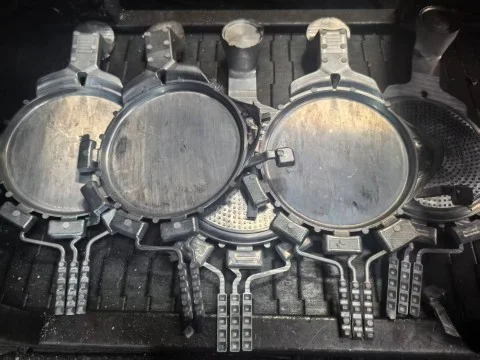

Die Preparation

The first step in the process is to prepare the die (also called the die). These dies are usually made of high-quality tool steel because the die casting process generates a lot of pressure and high temperatures, and the die must be able to withstand these harsh conditions. The operator will carefully clean the die and apply lubricant. This is done for two main purposes: one is to allow the molten metal to flow smoothly into every corner of the die, and the other is to make it easier to remove the final molded part from the die after it is completed.

Metal Preparation

The next step is to prepare the metal to be die-casted. Unlike hot chamber die casting (where the metal is melted inside the machine), cold chamber die casting requires the metal to be heated and melted in a separate furnace outside the machine. Once the metal is completely molten and liquid, it is scooped up and transferred to the injection chamber of the die casting machine. This step is critical because it allows us to better control the melting process (such as precise temperature control) and also reduces the risk of impurities mixed into the molten metal.

Injection of Molten Metal

We inject liquid metal into the mold cavity under high pressure. The pressure ranges from hundreds to thousands of pounds per square inch (psi), depending on the size and complexity of the workpiece. The injection speed is precisely controlled during the operation to ensure that the metal quickly and completely fills the mold cavity, thereby reducing the occurrence of defects such as bubbles.

Cooling and Solidification

The metal begins to cool and solidify immediately after being injected into the mold. The mold itself has a cooling function that can accelerate the cooling of the metal. Which helps to form a tighter internal structure and improve the mechanical properties of the workpiece. We monitor the cooling process throughout the process to ensure that the metal solidifies evenly and avoid quality problems such as shrinkage or looseness.

Ejection of the Part

When the metal solidifies in the mold, the mold opens automatically. At this point, the operator uses pre-set ejectors to smoothly push the molded part out of the mold. The layout of these ejectors is carefully calculated to ensure that the part will not be damaged during the removal process. After the part is removed, the quality inspector will immediately screen for defects. If burrs or dimensional deviations are found, a finishing process will be arranged later. Such as cutting off excess material edges, adjusting the dimensional accuracy of key parts. Or improving surface properties through processes such as spraying and electroplating.

Post-Processing

After completing the above steps, the part enters the final processing stage. This stage may include three key operations: first, use special equipment to trim the residual material on the edge of the part. Second, machine the parts with high precision requirements; and finally implement surface treatment (such as painting or plating) as required. These operations are necessary processes to ensure that the parts fully meet the design drawings and customer quality requirements.

Applications & Industry Advantages

Core Applications

- Automotive: Engine blocks, transmission housings (lightweight + high strength).

- Aerospace: Turbine blades, structural brackets (precision + durability) .

- Electronics: Smartphone casings, heat sinks (excellent surface finish) .

- Industrial: Pump housings, valve bodies (high-volume production) .

Advantages vs. Hot Chamber Process

| Aspect | Cold Chamber | Hot Chamber |

| Metal Suitability | High-melting alloys (Al, Cu) | Low-melting alloys (Zn, Mg) |

| Tool Life | Longer (no molten metal exposure) | Shorter (corrosion risk) |

| Part Size | Large, complex components | Small-to-medium parts |

| Surface Finish | Superior (low porosity) | Good but less refined |

| Automation | Easier for high-pressure systems | Limited by integrated furnace |

HAICHEN Die Casting Machine Manufacturer

HAICHEN is a die-casting machine manufacturer with 20 years of industry experience. Focusing on providing cold chamber die-casting machine equipment and production solutions for global customers. Our factory is located in Ningbo, China, equipped with complete R&D, production and training facilities. The clamping force of the die-casting machines produced by us ranges from 500 to 30,000 kN. Which can meet the production needs of aluminum and magnesium alloy parts for enterprises of different sizes.

In terms of equipment characteristics, HAICHEN’s cold chamber die-casting machine adopts servo-controlled hydraulic system and real-time precision control system, and has high-speed injection capability. In order to reduce customer production costs, we have optimized the energy consumption design of the equipment. Such as separating the structure of the furnace and the injection unit (suitable for aluminum and magnesium alloys with a melting temperature of over 700°C). Ensuring stable operation of the equipment while reducing energy loss.

HAICHEN Application Example

Take producing a 280mm aluminum fry pan with thin walls (2.8mm) and deep cavity. The HAICHEN 650T cold chamber machine uses multi-stage servo injection for smooth, high-speed filling and precise mold temperature control for even solidification. This achieved a stable cycle time under 45 seconds and a product yield rate over 98.5%.

The operation steps of the cold chamber die casting process are the key to producing high-quality metal parts. From mold preparation to final processing, every link needs to be strictly controlled to ensure that the finished product meets the quality requirements.