Characteristics of aluminum material include its lightweight nature, high strength, excellent corrosion resistance, good thermal conductivity.

Aluminum is a widely used material in the die casting industry, and its unique characteristics make it an ideal choice for a variety of applications.

Its versatility and performance attributes have led to its extensive use across numerous sectors, including automotive, aerospace, electronics, and consumer goods.

In this article, we will explore the key characteristics of aluminum material that make it so popular in die casting and how these properties contribute to the production of high-quality, durable, and efficient components.

Characteristics of aluminum material

- Lightweight

- High Strength

- Excellent Corrosion Resistance

- Good Thermal Conductivity

- Recyclability

Lightweight

One of the most significant advantages of aluminum is its lightweight nature. Aluminum has a density of approximately 2.7 grams per cubic centimeter (g/cm³), making it much lighter than traditional materials like steel. This lightweight property is crucial for applications where weight reduction is essential, such as in the automotive and aerospace industries. Using aluminum can significantly improve fuel efficiency and overall performance.

High Strength

Despite its low weight, aluminum offers high strength. Through various alloying processes, aluminum can achieve mechanical properties that are comparable to those of steel. This makes it suitable for structural components that require both strength and durability. For example, aluminum alloys like 6061 and 7075 are commonly used in applications where high strength and low weight are critical.

Excellent Corrosion Resistance

Aluminum naturally forms a thin oxide layer on its surface when exposed to air. This oxide layer provides excellent corrosion resistance, making aluminum suitable for use in environments where it may be exposed to moisture or chemicals. This property is particularly important in outdoor applications and marine environments.

Good Thermal Conductivity

Aluminum has high thermal conductivity, making it an excellent material for applications that require efficient heat transfer. This property is utilized in the manufacturing of heat sinks, engine components, and other parts where thermal management is essential. The ability to dissipate heat quickly helps maintain optimal operating temperatures and enhances the performance and reliability of the product.

Recyclability

Aluminum is highly recyclable, which makes it an environmentally friendly choice. Recycled aluminum retains its properties and can be reused multiple times without significant degradation. This reduces the demand for raw materials and helps minimize waste, contributing to a more sustainable manufacturing process.

Design Considerations for Aluminum Die Castings

- Structural Optimization Design

- Wall Thickness Uniformity Control

Structural Optimization Design

In HAICHEN’s engineering practice, we place special emphasis on structural optimization of aluminum die castings. Through advanced simulation software, we can predict material flow and solidification behavior during the design phase, thereby optimizing part structures to maximize the performance advantages of aluminum material.

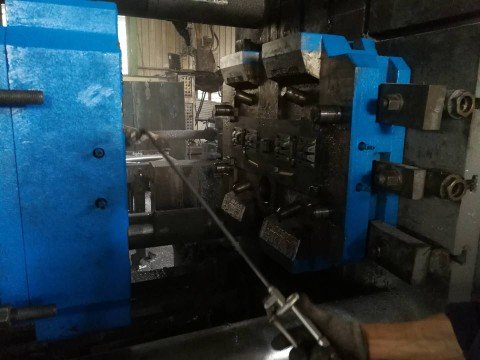

Wall Thickness Uniformity Control

The wall thickness uniformity of aluminum die castings directly affects product quality. HAICHEN die casting machines are equipped with precise injection control systems that ensure consistent wall thickness distribution when producing aluminum components with complex geometries, preventing defect formation.

Industry Applications of Aluminum Die Castings

- Automotive Lightweight Applications

- Electronic Thermal Solutions

Automotive Lightweight Applications

In the automotive industry, HAICHEN provides aluminum alloy die casting solutions for several well-known manufacturers, including engine components, transmission housings, and structural parts. Our aluminum die casting technology helps customers achieve significant lightweight effects while ensuring parts meet strict safety and performance requirements.

Electronic Thermal Solutions

Leveraging aluminum’s excellent thermal properties, HAICHEN has specifically developed die casting solutions for electronic device heat dissipation. Our aluminum die cast heat sinks are widely used in 5G base stations, high-performance computers, and consumer electronics, providing outstanding thermal management performance.

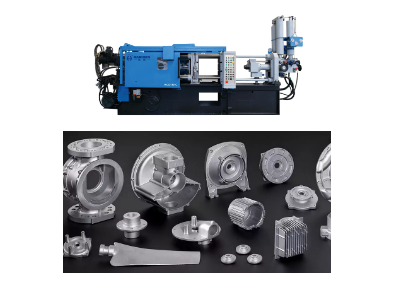

HAICHEN: Professional Die Casting Machine Manufacturer

- Advanced Technology Platform

- Professional Technical Support

- Sustainable Manufacturing Practices

Advanced Technology Platform

HAICHEN die casting machines employ advanced technology platforms specifically optimized for aluminum alloy characteristics. Our equipment features high injection speeds and pressure control accuracy, ensuring full utilization of aluminum material performance potential. Intelligent control systems monitor process parameters in real-time, guaranteeing consistently high quality for every aluminum die casting product.

Professional Technical Support

HAICHEN provides comprehensive after-sales services, including specialized technical support for aluminum alloy die casting, spare parts supply, and operational training. Our engineering team has deep knowledge of aluminum material characteristics and can provide customers with complete solutions from material selection to process optimization.

Sustainable Manufacturing Practices

Based on the recyclable characteristics of aluminum material, HAICHEN actively promotes sustainable manufacturing practices. Our die casting equipment supports the use of recycled aluminum materials while reducing energy consumption during production through energy-efficient designs, helping customers achieve environmentally friendly manufacturing goals.

The characteristics of aluminum material, including its lightweight nature, high strength, excellent corrosion resistance, good thermal conductivity, and recyclability, make it a popular choice for various manufacturing applications.