Controlling porosity in pressure die casting involves optimizing injection speed and pressure, ensuring proper mold venting, maintaining consistent metal temperature, and using high-quality alloys to minimize defects and improve part integrity.

Pressure die casting is a highly efficient manufacturing process widely used in various industries to produce complex metal parts with high precision and dimensional accuracy.

However, one of the most common challenges in this process is the control of porosity.

Porosity refers to the presence of voids or gas pockets within the cast part, which can significantly affect the mechanical properties, corrosion resistance, and overall quality of the final product.

In this article, we will explore the factors that contribute to porosity and discuss effective strategies to control and minimize it.

Understanding Porosity in Pressure Die Casting

Porosity in pressure die casting can be classified into two main types: gas porosity and shrinkage porosity.

Gas porosity occurs when air or other gases become trapped within the molten metal during the injection process. This can happen due to improper venting, high injection speeds, or poor mold design. Shrinkage porosity, on the other hand, results from the solidification process when the metal contracts as it cools, creating voids within the part. This type of porosity is often more challenging to detect and control.

Factors Affecting Porosity

- Injection Speed and Pressure

- Mold Design

- Metal Temperature

- Mold Temperature

- Material Quality

Injection Speed and Pressure

The speed at which the molten metal is injected into the mold plays a crucial role in porosity formation. Too high an injection speed can trap air within the metal, leading to gas porosity. Conversely, too low a speed may cause the metal to cool prematurely, resulting in shrinkage porosity. Finding the optimal injection speed and pressure is essential to minimize porosity.

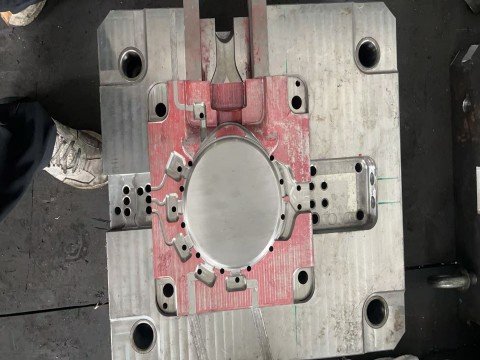

Mold Design

The design of the die casting mold has a significant impact on porosity. Proper venting channels are necessary to allow trapped air to escape during the injection process. Additionally, the mold should be designed to promote uniform metal flow and avoid areas where the metal can cool too quickly or too slowly.

Optimizing Mold Design to Control Porosity

Excellent mold design is the first line of defense against porosity. Haichen’s engineering team curbs porosity at its source through the following design practices:

- Intelligent Gating System Design: Utilizing computational fluid dynamics (CFD) simulations, the flow state of molten metal within the mold cavity is accurately analyzed. Based on this, the gate location, size, and direction are optimized to guide the molten metal to fill smoothly and sequentially, avoiding turbulent air entrapment. For example, for large, thin-walled parts, multi-branch tangential gates are often used, allowing the molten metal to fill along the mold wall and effectively expel gas.

- High-efficiency venting and overflow system: Venting and overflow channels are scientifically designed at the ends of the molten metal flow and in areas where air may be trapped (such as behind bosses and at thick-walled junctions). The venting channel depth is typically 0.05-0.15mm, ensuring smooth gas discharge without molten metal leakage. The overflow channel not only accommodates cold metal and impurities but also serves as an auxiliary venting channel and temperature buffer.

- Cavity surface and polishing technology: An overly rough cavity surface can hinder gas discharge along the parting line or ejector pin gaps. Haichen performs high-precision polishing on the mold surfaces in critical areas (e.g., meeting VDI 3400 #A1 standards) to reduce flow resistance and promote gas escape.

Metal Temperature

The temperature of the molten metal is another critical factor. If the metal is too hot, it may cause excessive turbulence during injection, trapping air and creating gas porosity. If it is too cold, the metal may solidify too quickly, leading to shrinkage porosity. Maintaining a consistent and optimal metal temperature is vital for reducing porosity.

Mold Temperature

Similar to metal temperature, the temperature of the mold also affects porosity. A mold that is too cold can cause the metal to solidify too quickly, leading to shrinkage porosity. A mold that is too hot may result in gas porosity due to increased turbulence. Proper mold temperature control is essential for consistent casting quality.

Precise Mold Temperature Control

The uniformity of the mold temperature field is crucial for controlling shrinkage and porosity and ensuring dimensional stability. Haichen’s intelligent temperature control system achieves precise management in this regard:

- Zoned Closed-Loop Temperature Control: For large or complex molds, the heat dissipation conditions vary significantly across different areas. Haichen employs multi-zone independent mold temperature control, installing thermocouples in each critical area (such as the gate, thick-walled sections, and core) to provide real-time temperature data feedback. The control system independently adjusts the flow rate and temperature of the cooling water channels in each zone, ensuring the temperature difference across the entire mold surface is controlled within ±5°C, achieving uniform solidification.

- Variable Temperature Control Technology (TCM): For parts with extremely high appearance requirements or particularly complex structures, Haichen can apply variable temperature control. Before injection, the mold surface is rapidly raised to a high temperature (e.g., above 180°C) using high-temperature steam or induction heating to improve fillability; after filling, it immediately switches to high-pressure cold water for rapid cooling, ensuring both surface quality and high efficiency.

- Point cooling and conformal water channels: In local hot spots of the mold (such as the core and thick-walled areas), the cooling efficiency of traditional straight water channels is insufficient. Haichen uses point cooling plugs (Baffle/Bubbler) or more advanced 3D printed conformal cooling water channels to make the cooling medium as close as possible to the cavity surface, achieving efficient and directional heat removal and preventing shrinkage cavities caused by slow local cooling.

Material Quality

The quality of the metal alloy used in the casting process can also influence porosity. Impurities or inclusions in the metal can act as nucleation sites for gas bubbles, increasing the likelihood of gas porosity. Using high-quality, clean metal alloys is important for minimizing porosity.

Strategies to Control Porosity

- Optimize Process Parameters

- Improve Mold Design

- Implement Vacuum-Assisted Casting

- Use of High-Quality Equipment

- Post-Processing Techniques

Optimize Process Parameters

Fine-tuning injection speed, pressure, and metal temperature is crucial. Advanced simulation software can be used to model the casting process and identify optimal parameters for minimizing porosity. Regular monitoring and adjustment of these parameters during production are also necessary to ensure consistent quality.

Improve Mold Design

Investing in high-quality mold design and engineering is essential. Proper venting channels, gating systems, and mold geometry can significantly reduce the risk of porosity. Regular maintenance and inspection of the mold are also important to ensure it remains in optimal condition.

Implement Vacuum-Assisted Casting

Vacuum-assisted pressure die casting can help reduce gas porosity by removing trapped air from the mold cavity during the injection process. This technique is particularly useful for complex parts where traditional venting may not be sufficient.

Use of High-Quality Equipment

The choice of die casting machine can also impact porosity control. Machines from reputable manufacturers, such as HAICHEN, are designed with advanced features that enhance process control and precision. HAICHEN’s die casting machines are known for their reliability, accuracy, and ability to maintain consistent process parameters, making them an excellent choice for high-quality casting production.

Post-Processing Techniques

In some cases, post-processing techniques such as heat treatment or infiltration can be used to mitigate the effects of porosity. Heat treatment can help reduce shrinkage porosity by improving the mechanical properties of the part. Infiltration involves filling porosity with a secondary material to enhance strength and corrosion resistance.

HAICHEN’s Porosity Control Technology System

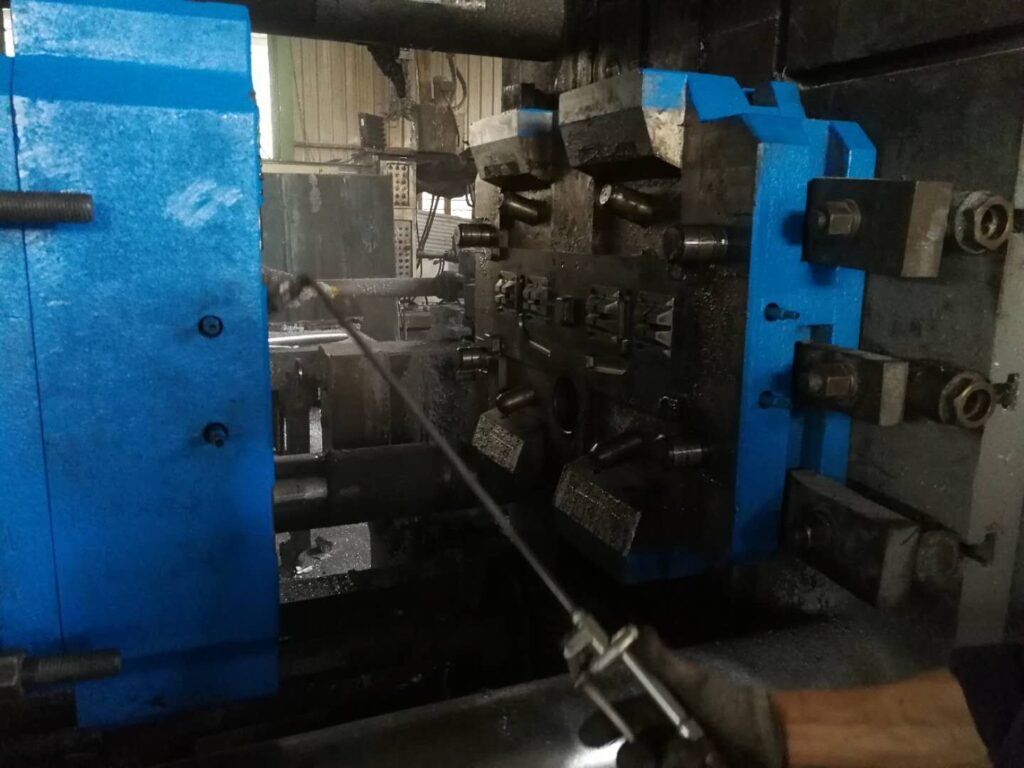

Precision Injection Control System

HAICHEN die casting machines are equipped with advanced injection control systems that implement a “slow-fast-slow” multi-stage injection process. By precisely controlling the injection curve, we ensure smooth cavity filling of molten metal, effectively reducing turbulence and gas entrapment. Our real-time pressure feedback system can adjust injection parameters at the millisecond level, maintaining porosity control at industry-leading standards.

Intelligent Temperature Management System

HAICHEN has developed a unique dual-closed-loop temperature control technology that precisely regulates both mold temperature and metal temperature simultaneously. The system monitors temperature changes in real-time through sensors distributed at key positions of the mold, automatically adjusting cooling channel flow rates to ensure uniform temperature distribution across all mold areas, effectively preventing shrinkage porosity caused by temperature variations.

Vacuum-Assisted Die Casting Technology

HAICHEN’s high-vacuum die casting system can achieve cavity vacuum levels above 95% within 0.3 seconds, significantly reducing residual gases in the mold cavity. This system is particularly suitable for producing structural components requiring high density, such as automotive safety parts and aerospace components, reducing porosity by over 60% compared to conventional die casting.

Mold Optimization Design Services

HAICHEN provides professional mold design optimization services based on computational fluid dynamics simulation analysis. Our engineering team optimizes the gating and overflow system design by adjusting gate positions, overflow well layouts, and venting channel designs, ensuring orderly filling of molten metal and smooth gas evacuation from the mold cavity, reducing porosity formation at the source.

HAICHEN Die Casting’s Solution

As a professional manufacturer with over 20 years of experience in die-casting machine development, HAICHEN provides hot and cold chamber die-casting equipment for aluminum, zinc, magnesium, and other alloys.

These machines feature precise pressure curve control, a fast-response injection system, and intelligent temperature monitoring, enabling a “slow-fast-slow” pressure-holding strategy to significantly reduce the formation of air holes and shrinkage pores.

Controlling porosity in pressure die casting is a multifaceted challenge that requires careful consideration of process parameters, mold design, material quality, and equipment selection. By understanding the factors that contribute to porosity and implementing effective strategies to minimize it, manufacturers can produce high-quality castings with improved mechanical properties and durability.