Avoid aluminium casts shrinkage voids includes optimize the design, control and control the cooling process and so on.

To avoid shrinkage voids in aluminum castings, please see below following measures:

1. Avoid aluminium casts shrinkage voids: Optimize the design

Avoid thick-walled areas: Thick-walled areas are more prone to shrinkage, which can form internal voids. Designers should minimize the design of thick-walled areas and add ribs to disperse stress when necessary.

Rationally arrange the gating system: Ensure that the gating system can effectively transport the molten metal to all parts of the casting to avoid local overheating and uneven cooling.

Use feeders: Place feeders in areas prone to voids to replenish the molten metal lost during shrinkage.

2. Avoid aluminium casts shrinkage voids: Control the cooling process

Uniform cooling: Ensure that the cooling process of the casting is uniform, especially in the thick wall area. This can be achieved by adding cooling ribs or cooling rings.

Control the cooling rate: Too fast cooling will lead to the formation of shrinkage cavities, so the cooling rate need to adjust appropriately.

3. Avoid aluminium casts shrinkage voids: Improve casting process

Optimize pouring temperature and speed: Control pouring temperature and speed to avoid shrinkage voids caused by excessive temperature or excessive speed.

Use vacuum-assisted casting: Vacuum-assisted casting technology can effectively reduce gas content, thereby reducing the formation of shrinkage voids.

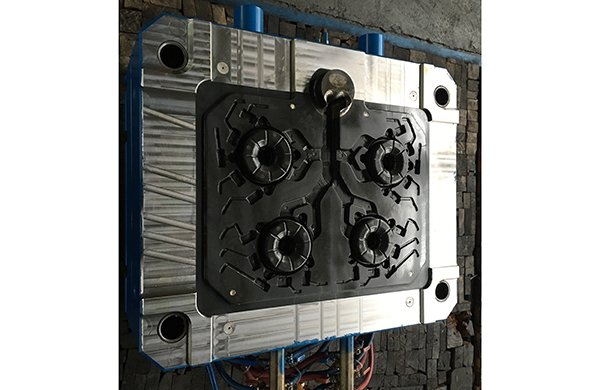

4. Improve mold design

Optimize mold venting: Ensure good venting channels in the mold design to reduce gas capture and void formation.

Use high-quality sand cores and sand molds: Choose sand core and sand mold materials that are dry and free of organic impurities to reduce gas generation.

5. Post-processing methods

Machining: For inevitable shrinkage cavities, they can trimme by machining.

Filling with resin or sealant: In the critical pressure areas, vacuum impregnation technology can use to fill the cavities with resin or sealant to seal them.

6. Experimental and simulation optimization

Heat transfer simulation: Predict the heat transfer process of castings through computer simulation technology, optimize mold and process parameters to reduce the formation of shrinkage cavities.

Gas control: By controlling the release of hydrogen, shrinkage cavities can replace by smaller spherical pores. Thereby improving the fatigue life of castings.

Thus, through the above measures, the shrinkage voids in aluminum castings can effectively reduce. And it can improve the quality and performance of castings.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.