Aluminum is the most widely used material for die casting.

Aluminum alloy is the most widely used material in die casting due to its lightweight, high strength-to-weight ratio, good corrosion resistance, and excellent mechanical properties.

Among them, aluminum alloy A380 (ANSI/AA A380.0) is the most widely used specific alloy grade, which provides the best combination of performance and ease of processing.

And is suitable for a variety of applications such as electronic equipment, automotive components, and communication equipment.

Aluminum properties

- Lightweight

- High Strength-to-Weight Ratio

- Corrosion Resistance

- Excellent Thermal and Electrical Conductivity

- Dimensional Stability

- Recyclability

Additionally, aluminum’s recyclability and versatility further contribute to its popularity in the die casting industry.

Aluminum is highly valued for its lightweight nature, high strength, and corrosion resistance.

These properties make it ideal for a wide range of applications, including automotive parts, aircraft components, household appliances, and electronic devices.

Lightweight

Aluminum has a low density, making it ideal for applications where weight reduction is critical, such as in the automotive and aerospace industries.

High Strength-to-Weight Ratio

Aluminum alloys used in die casting offer good strength while remaining lightweight.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it resistant to corrosion.

Excellent Thermal and Electrical Conductivity

Using aluminum widely used in components that require heat dissipation or electrical conductivity.

Dimensional Stability

Aluminum die cast parts maintain their shape and dimensions even under varying temperatures.

Recyclability

Aluminum is highly recyclable, making it an environmentally friendly choice.

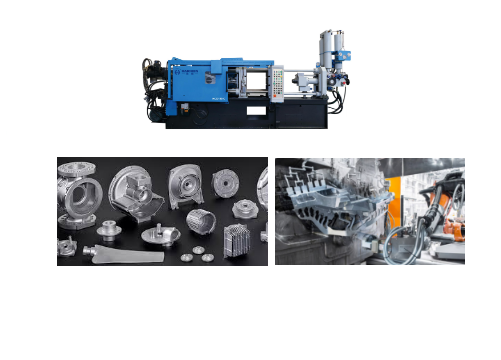

Applications of Aluminum Alloy Die Casting

Automotive: Engine components, transmission housings, brackets, and structural parts.

Aerospace: Lightweight structural components and housings.

Electronics: Heat sinks, housings, and connectors.

Consumer Goods: Appliance components, power tools, and decorative hardware.

Industrial Machinery: Pump housings, valves, and hydraulic components.

Other commonly used materials for die casting

- Zinc (Zinc)

- Magnesium

Zinc (Zinc)

Zinc alloy is another commonly used die casting material with excellent corrosion resistance, ease of casting and high dimensional accuracy.

Actually,hot chamber die casting machines usually produce zinc die castings, which are suitable for manufacturing thin-walled and complex-shaped parts.

Their excellent mechanical properties and machinability make them widely used in die casting.

Magnesium

Magnesium alloys are the lightest die castable metal available, with high strength and good thermal properties.

Then cold chamber die casting machines typically produce magnesium alloy die castings, which are suitable for manufacturing parts that require light weight and high strength.

Then their low density and high strength make them widely used in the aerospace and automotive industries.

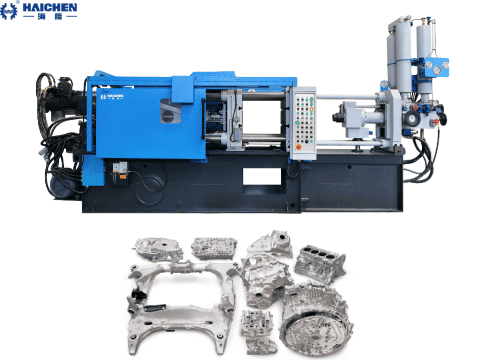

Haichen die casting machines supplier

Haichen is a well-known manufacturer and supplier of die casting machines, particularly recognized for producing high-quality cold chamber die casting machine, hot chamber die casting machines and auxiliary equipments.

We cater to a wide range of industries, including automotive, electronics, and consumer goods.

Reliability, precision, and advanced technology make Haichen’s machines a popular choice for die casting operations worldwide.

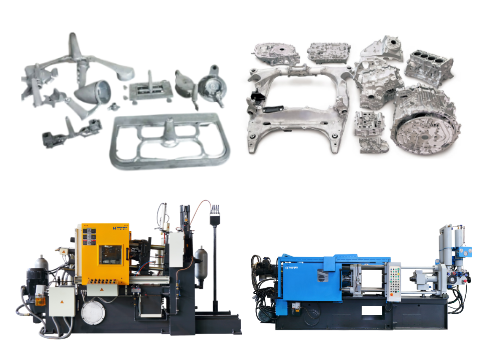

Key Features of Haichen Die Casting Machines

High Precision and Efficiency: Haichen machines are designed for high-performance die casting, thereby ensuring consistent quality and productivity.

Advanced Control Systems: Haichen die casting machines often come with user-friendly PLC (Programmable Logic Controller) systems for precise control over the casting process.

Durable Construction: High-quality materials build Haichen machines, giving them longevity and low maintenance requirements.

Wide Range of Models: We offer machines with varying clamping forces, making them suitable for small to large-scale production needs.

Customization Options: Haichen provides tailored solutions to meet specific customer requirements.