Die casting cooling solutions includes choice of cooling method, cooling medium, cooling system maintenance and so on.

Die casting cooling solutions require the coordination of material selection (such as H13 steel for thermal fatigue resistance), mold heat treatment (three tempering + graded quenching to increase life), part heat treatment (T6/Auraltherm to optimize performance) and cooling system design (uniform temperature control). The ultimate goal is to achieve the unity of long mold life and high part performance through precise heat treatment parameters (temperature/time/cooling rate) and material engineering.

The cooling system plays a vital role in the die casting process, which directly affects the surface quality, dimensional accuracy and reduction of internal defects of the die casting. If the cooling is not done properly, it may lead to surface defects. Also with shrinkage and increased porosity of the die casting.

- Choice of cooling method of die casting cooling solutions

- Choice of cooling medium of die casting cooling solutions

- Die casting cooling solution: Cooling system maintenance

- Material selection and heat treatment

Choice of cooling method of die casting cooling solutions

- Water cooling

- Water cooling principle

- Advantages of water cooling

- Disadvantages of water cooling

- Applicable scenarios

- Air cooling

- Oil Cooling

- Spray/Mist Cooling

Water cooling

Water cooling one of the most common used cooling methods. With high cooling efficiency, but it will increase the complexity of the mold structure. Water cooling channels usually arrange in the core or insert of the mold to effectively remove heat. One of water coolings for example like water cooling chiller

Water cooling principle

Heat is dissipated through the circulating water channel drilled inside the mold, usually with a chiller to maintain a constant temperature.

Advantages of water cooling

- Efficient heat dissipation: The high heat capacity of water can quickly reduce the mold temperature and shorten the cycle time (it can significantly improve production efficiency).

- Low cost: Water resources are easily available and the system construction is economical.

- Precise temperature control: By adjusting the flow rate, high-temperature areas (such as thick-walled areas) can be cooled in a targeted manner.

Disadvantages of water cooling

- Corrosion and scaling risks: Long-term use may block the channel and require regular maintenance.

- Thermal shock risk: Improper temperature control can easily lead to mold cracking.

Applicable scenarios

- Mass production (such as automobile engine cylinder blocks).

- Aluminum alloy die casting (due to the high thermal conductivity of aluminum, rapid cooling is required).

Air cooling

Air cooling is a lower-cost cooling method. And it is suitable for occasions where rapid cooling is required. However, air is less efficient as a cooling medium, not as good as water or oil.

Air cooling principle

Rely on natural air or fan forced heat dissipation, no complex piping.

Advantages

- Extremely low cost: no cooling medium and circulation system required.

- No corrosion risk: suitable for simple production environment.

Disadvantages

- Low efficiency: only suitable for small or thin-walled parts.

- Uneven cooling: easy to cause part warping.

Applicable scenarios

- Prototype trial production or small batch zinc alloy parts.

- Low production scenario.

Oil Cooling

Oil cooling principle

Use hot oil (200–300°C) as a cooling medium, suitable for high-temperature molds.

Oil cooling advantages

- Good thermal stability: not easy to vaporize at high temperatures, suitable for materials that need to be cooled slowly, such as magnesium alloys.

- Reduced thermal stress: Avoid cracks in the mold due to rapid cooling.

Disadvantages

- Complicated maintenance: Difficult to clean oil stains and there is a risk of fire.

- Low heat dissipation efficiency: Slower than water cooling, may extend the cycle.

Applicable scenarios

- Magnesium alloy die casting (such as laptop computer shell).

- Molds that require high temperature operation.

Spray/Mist Cooling

Principle

Spray water or coolant droplets onto the mold surface to quickly absorb heat.

Advantages

- Local efficient cooling: especially suitable for heat dissipation in thick-walled areas.

- Flexibility: nozzle position and spray pattern are adjustable.

Disadvantages

- Drainage requirements: a matching collection system is required.

- Risk of thermal shock: excessive use may damage the mold.

Applicable scenarios

- Large parts (such as aluminum wheels).

- Hot spots in molds (such as the spray cooling technology mentioned).

Choice of cooling medium of die casting cooling solutions

Water cooling usually uses water preheated to about 50°C to avoid overheating risks.

The temperature of the cooling water should be above room temperature to prevent condensation on the surface. Air cooling requires fan-driven air circulation.

- Water cooling system

- Oil cooling system

- Air cooling system

- High-pressure pulsating water cooling (HPPC/Jet Cooling)

- Selection basis and key influencing factors

Water cooling system

The most widely used method is to circulate cold water through the internal channels of the mold (usually in conjunction with a cooling tower or chiller) to achieve efficient heat dissipation.

Its advantages are low cost and high heat conduction efficiency (surface cooling rate can reach more than 28°C/min), which is suitable for mass production (such as automotive parts).

However, it should be noted that the water temperature must be controlled above 20°C to avoid mold thermal shock cracking; improper water quality management may cause corrosion.

Oil cooling system

Use hot oil (working temperature 200–300°C) as a medium, suitable for die casting of high-temperature alloys (such as magnesium alloys).

The advantage is good high-temperature stability, which can reduce the risk of mold thermal stress cracking; the disadvantage is that maintenance is complicated, there is a fire hazard, and the heat conduction efficiency is lower than water. In specific scenarios (such as the fixed mold part of the mold), oil cooling can reduce surface defects of castings.

Air cooling system

The heat is dissipated through compressed air or fans, with the lowest cost and no corrosion risk.

However, the cooling efficiency is low, which can easily lead to uneven cooling and casting deformation, and is only suitable for small parts or low-volume scenarios (such as zinc alloy prototypes).

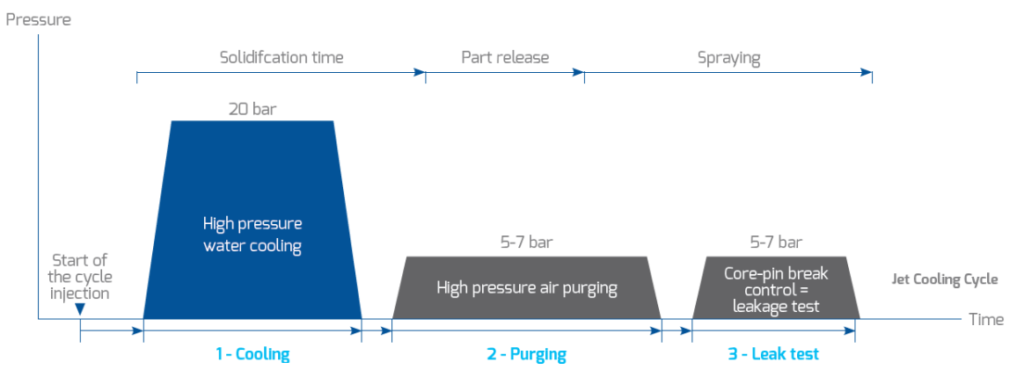

High-pressure pulsating water cooling (HPPC/Jet Cooling)

For local high-temperature areas (such as core pins), high-pressure water pulses are used to precisely control cooling, reduce shrinkage and erosion problems, and reduce mold maintenance requirements

The Concept and role of Jet Cooling in Die Casting

Basic Principle: High-pressure water jets are used to directly impact hot spots inside the mold (such as core pins and thin-walled inserts) through specialized nozzles (Jet Coolers). This removes a large amount of heat in a very short time, achieving rapid localized cooling.

Selection basis and key influencing factors

Material properties

- Mold materials: High thermal conductivity materials (such as copper and aluminum alloys) can dissipate heat quickly, but the cost is higher than steel.

- Steel molds require more active cooling strategies (such as water cooling).

Casting alloys

Aluminum alloys have high thermal conductivity and are suitable for water cooling; magnesium alloys need to be cooled slowly to avoid cracking, and oil cooling is suitable.

Haichen die casting cooling solutions

Achieve superior die casting quality and efficiency with Haichen’s advanced die casting cooling solutions. Proper thermal management is critical for reducing cycle times, minimizing defects like porosity, and extending mold life. Haichen specializes in high-performance cooling systems, including optimized channel designs and temperature control units, that ensure precise and consistent cooling throughout the production process. If you’re looking to enhance your die casting operation’s output and quality, trust Haichen’s expertise in thermal management. Please visit Haichen to discover cooling solutions.

Die casting cooling solutions : Cooling system maintenance

- Extend mold life

- Improve product quality

- Optimize production efficiency

High-pressure and high-temperature hoses and connections in the cooling system require regular inspection and maintenance to prevent leakage and fire risks.

Cooling system maintenance also includes regular cleaning of filters to prevent casting residues from entering the circulation pump.

Extend mold life

Avoid mold cracking or deformation caused by thermal stress due to overheating, point out that insufficient cooling will accelerate mold wear and emphasize that uniform cooling can reduce thermal stress and extend mold life.

Mention that thermally balanced molds can reduce the need for external spraying and reduce maintenance costs.

Improve product quality

Both point out that uneven cooling can cause defects such as shrinkage, thermal stress, and deformation. Explain that precise temperature control can reduce porosity and cracks and improve surface finish.

Optimize production efficiency

Fast cooling can shorten cycle time, but warns that cooling too quickly may increase internal stress and cause cracks.

Material selection and heat treatment

The design of the cooling system also needs to consider the thermal shock resistance, toughness and high temperature strength of the mold material.

For example, H13 steel widely uses in die casting molds. Due to its excellent mechanical properties and thermal fatigue resistance.

Appropriate heat treatment processes (such as graded isothermal quenching) can effectively reduce mold deformation and cracking.

Thus, the die casting cooling solution needs to comprehensively consider cooling methods, channel design, medium selection, maintenance and optimization, etc. Through scientific design and reasonable management, the quality and production efficiency of die castings can be significantly improved.