An aluminum alloy road stud die casting machine is highly recommended for producing road studs due to its efficiency, precision, and ability to create durable, high-quality products.

The aluminum alloy road studs commonly known as curb stones. They are typically produced using cold-chamber die casting. Cold-chamber die casting machines provide sufficient clamping force and injection pressure for alloys with high melting points (such as ADC12 and A380 aluminum alloys). Ensuring rapid filling and uniform solidification of molten aluminum within the mold cavity. This process yields curb stones with high dimensional accuracy, smooth surfaces, and reliable strength.

The recommendation of an aluminum die casting machine depends on a number of factors, including the type of aluminum alloy, the technical characteristics of the die casting machine, and the specific needs of the application.

- Determine Production Requirements of alloy road stud die casting machine

- Evaluate Key Technical Parameters

- Recommended aluminum alloy road stud machine auxiliary Equipment and Systems

- Additional Considerations

Determine Production Requirements of alloy road stud die casting machine

The production demand for aluminium alloy road studs production, mainly includes below aspects:

Product Specifications

- Product Specifications

- Material

- Choose the Right Type of Die Casting Machine

The aluminium road studs have different types on the market. Firstly need to clarify the size, shape, material, and production volume of the road studs. For example, for road studs with dimensions of 100×100×20 mm, a machine with sufficient clamping force and mold size is necessary.

Material

Ensure the machine is suitable for aluminum alloy, which requires high melting point handling and high-pressure injection.

Choose the Right Type of Die Casting Machine

Cold Chamber die casting machine : For aluminum, cold chamber die casting machines are recommended due to their suitability for high melting point materials. These machines provide higher compressive strength and product integrity.

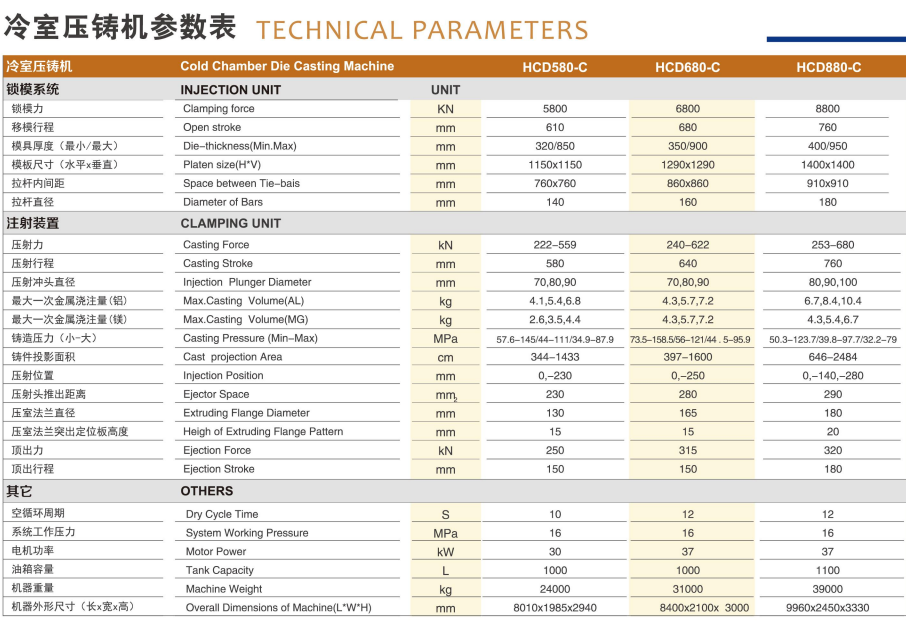

Evaluate Key Technical Parameters

- Clamping Force

- Mold Size

- Injection Pressure and Speed

- Ejection Force

Clamping Force

The machine should have sufficient clamping force to prevent mold separation during injection. For example, a 300-ton horizontal cold chamber die casting machine with a clamping force of 3000 kN is suitable for small to medium-sized aluminum parts.

Mold Size

Ensure the mold size can accommodate the road stud dimensions. For instance, a mold size of 900×900 mm is adequate for producing two-cavity road studs.

Injection Pressure and Speed

The machine should have adjustable injection pressure and speed to suit the complexity and wall thickness of the road studs. Aluminum typically requires injection pressures between 30,000 to 60,000 kPa.

Ejection Force

Ensure the ejection force is suitable for lightweight aluminum parts.

Other aluminum alloy road stud die casting machine

Key Advantages of Haichen Cold Chamber Die Casting Machines

High-Performance Structure for Demanding Processes

HAICHEN cold chamber die casting machines feature high-strength integral frames and optimized clamping systems capable of withstanding extreme internal pressures generated during the injection of high-melting-point metals like aluminum and magnesium alloys.

High precision and evenly distributed clamping force effectively prevent flash, ensuring dimensional stability and internal density for large or complex parts (e.g., automotive structural components, motor housings).

Precise and Flexible Process Control

Equipped with high-performance servo control systems, they enable multi-stage precise control over injection speed, pressure, and stroke.

This is crucial for parts with thin walls, high surface requirements, or needing local reinforcement. Fine-tuning process parameters significantly reduces scrap rates and improves material yield.

Exceptional Reliability and Durability

Critical hydraulic and electrical components from internationally renowned brands, combined with scientific circulatory cooling and filtration systems.

That ensures equipment stability under continuous high-load operation.

Recommended aluminum alloy road stud machine auxiliary Equipment and Systems

- Consider the Degree of Automation

- Control System and Precision

- Manufacturer Reputation and Support

- Cost and Budget of alloy road stud die casting machine

Consider the Degree of Automation

Machines with higher automation levels can reduce manual intervention, increase production efficiency, and lower labor costs. This is particularly important for high-volume production.

Control System and Precision

Select machines with advanced control systems to ensure precise control and real-time monitoring. This helps in maintaining consistent quality and reducing defects.

Manufacturer Reputation and Support

Choose a reputable manufacturer known for high-quality machines and reliable after-sales service. For example, Haichen is a well-regarded supplier that offers comprehensive support, including installation, commissioning, and maintenance services.

Cost and Budget of alloy road stud die casting machine

Ensure the machine fits within your budget while meeting all necessary technical requirements. Consider both the initial investment and long-term operational costs.

Additional Considerations

- Cooling Time and Cycle Efficiency

- Mold Life and Maintenance

Cooling Time and Cycle Efficiency

Calculate the cooling time based on the thickness of the road studs to optimize production cycles.

Mold Life and Maintenance

Consider the mold material (e.g., H13 steel) and maintenance requirements to ensure longevity and consistent performance.

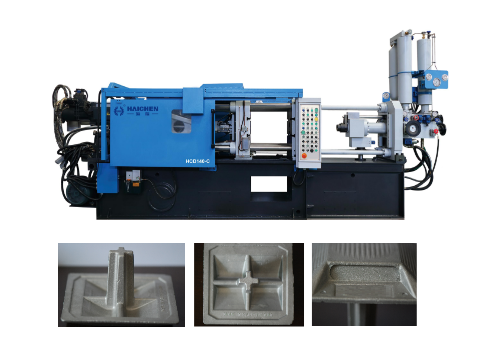

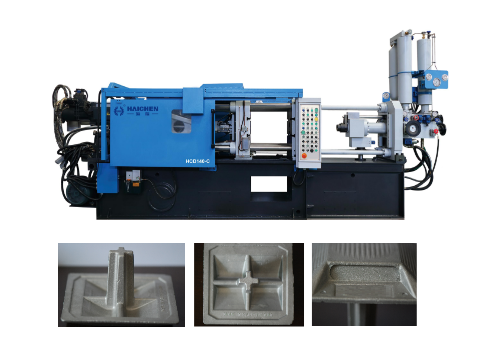

Haichen Aluminum Alloy Road Stud die casting machine

Haichen is a well known manufacturer of cold chamber die casting machines, specializing in die casting production solutions for aluminum, magnesium, zinc and copper alloys.

For producing 100×100×20 mm aluminum road studs, a 300-ton horizontal cold chamber die casting machine is highly recommended. Machines like the Haichen HCD-C model offer sufficient clamping force (3000 kN), mold size (900×900 mm), and adjustable injection parameters, making them ideal for this application.

If you need to know more about Haichen’s die casting machines or customized solutions, please feel free to contact us.