To solve deformation during die casting by optimize design, control process parameters, balance cooling, and reasonable ejection can reduce it significantly.

To solve deformation during die casting process need start from many aspects. Including optimizing mold design, adjusting process parameters and improving material treatment.

- Optimize Mold Design

- Control Cooling Rate

- Adjust Process Parameters

- Material Selection

- Post-Casting Treatments

- Quality Control and Inspection

- Maintenance

Optimize Mold Design

Uniform Wall Thickness

Ensure the mold design has uniform wall thickness to avoid uneven cooling and shrinkage.

Proper Venting

Adequate venting helps in reducing gas entrapment, which can cause deformation.

Draft Angles

Incorporate appropriate draft angles to facilitate easy ejection of the part without causing deformation.

Control Cooling Rate

Uniform Cooling

Ensure that the cooling system is designed to provide uniform cooling across the entire part. Uneven cooling can lead to warping and deformation.

Cooling Channels

Optimize the placement and size of cooling channels to maintain consistent temperatures.

Adjust Process Parameters

Injection Pressure and Speed

Optimize the injection pressure and speed to ensure the molten metal fills the mold completely without causing excessive stress.

Temperature Control

Maintain consistent temperatures for both the molten metal and the mold. Too high or too low temperatures can lead to deformation.

Holding Pressure and Time

Proper holding pressure and time can help in reducing shrinkage and deformation.

Material Selection

Alloy Composition

Choose an alloy with good fluidity and minimal shrinkage characteristics.

Preheating

Preheating the mold can help in reducing thermal shock and subsequent deformation.

Post-Casting Treatments

Stress Relieving

Perform stress-relieving heat treatments to reduce internal stresses that can cause deformation.

Straightening

Mechanical straightening can be used to correct any deformation that occurs during casting.

Quality Control and Inspection

Dimensional Checks

Regularly inspect the dimensions of the cast parts to identify any deformation early in the process.

Process Monitoring

Use sensors and monitoring systems to keep track of process parameters and make real-time adjustments.

Maintenance

Regular Maintenance

Ensure that the die casting machine and mold are regularly maintained to prevent issues that could lead to deformation.

Mold Surface Treatment

Apply surface treatments to the mold to improve its durability and performance.

By addressing these factors, you can significantly reduce the risk of deformation during the die casting process and improve the overall quality of the cast parts.

Haichen die casting machine supplier

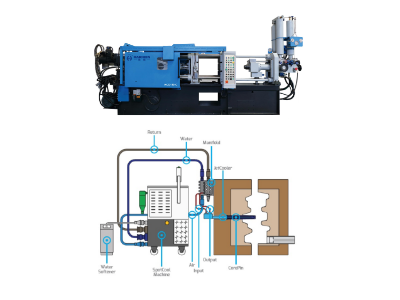

Haichen is a well-known manufacturer of die casting machines, based in China. We offer a range of die casting machines, including cold chamber die casting machines and hot chamber die casting machines, catering to various industries such as automotive, electronics, and home appliances.

Key Features of Haichen Die Casting Machines:

High Precision: Haichen machines are known for their high precision and stability, which are crucial for producing high-quality castings.

Energy Efficiency: Many of their machines are designed to be energy-efficient, reducing operational costs.

Advanced Control Systems: Equipped with advanced PLC control systems for better process control and automation.

Durability: Built with high-quality materials to ensure long service life and reliability.

Versatility: Capable of handling a wide range of materials, including aluminum, zinc, and magnesium alloys.