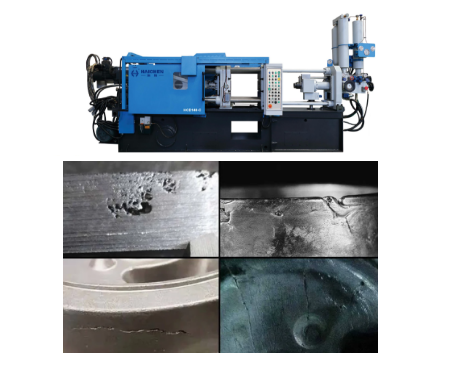

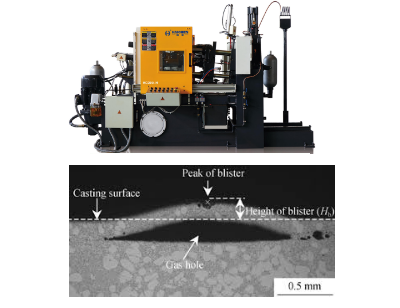

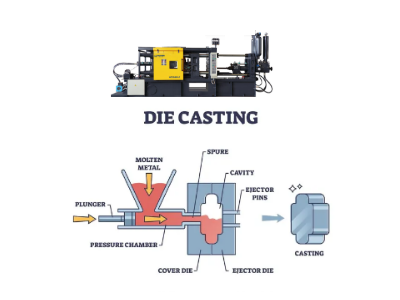

Blisters in die casting are surface defects that manifest as bulging or raised bubbles on the surface of the casting, usually caused by the expansion of trapped gas inside.

Air bubbles not only affect the appearance but can also damage the mechanical properties and airtightness of the casting, especially in subsequent processes such as electroplating or heat treatment.

Blisters in die casting, requiring comprehensive optimization in process control, mold design, material management, and equipment maintenance.

In Haichen’s understanding, blisters in the die casting process are a common defect, and their formation is closely related to factors such as gas, temperature control, and mold design.

Common causes of blisters in die casting process

- Gas in molten metal

- Unreasonable mold design

- Coating and release agent problems

- Filling and cooling process

- During solidification

Gas in molten metal

The filling of molten metal in the injection chamber is too low.

And the initial injection speed is too high, which is easy to produce coiled gas.

In addition, high melting temperatures, high gas content, and undegassed melt can also lead to the formation of bubbles.

Unreasonable mold design

Unreasonable design of the mold gating system, poor exhaust, excessive gas in the cavity.

Too high mold temperature or loss of function of the cooling channel will lead to the generation of bubbles.

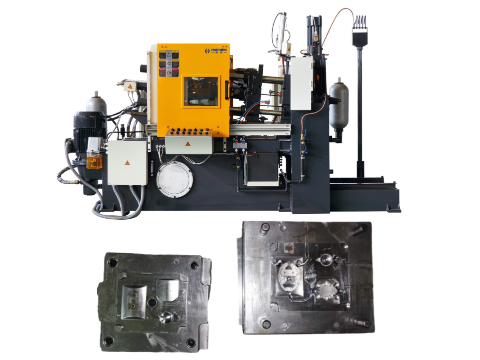

If bubbles appear in the die casting during mold trial, Haichen will re-optimize the mold design to solve this problem.

Such as improving exhaust, increasing cooling, controlling mold temperature, and adjusting filling speed and pressure.

Coating and release agent problems

Paint gas generation is large, too much is used, or the release agent is used in excess.

And unburned volatile gases are encapsulated on the surface of the casting, which can also cause bubbles.

Filling and cooling process

Too high a filling rate traps excessive gas in the metal stream, and rapid cooling makes the gas expand and form bubbles.

In addition, opening the mold too early allows pressurized gas to expand and create bubbles.

Alloy composition and treatment: the gas content of the alloy liquid is too high, and it is precipitated.

During solidification

Incomplete degassing of aluminum alloy liquids will also lead to bubbles.

Other factors, such as too high mold temperature, too fast filling speed, too high melting temperature.

Too high mold temperature, not enough mold retention time, etc., will affect the formation of bubbles.

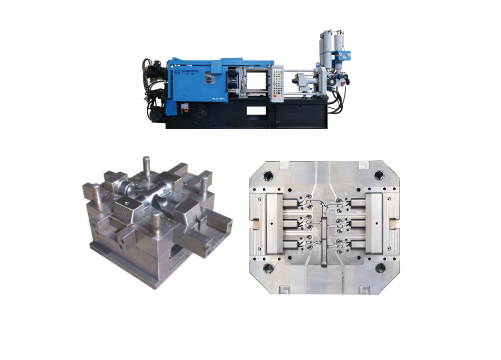

Blisters and mould design

- Mold exhaust design

- Mold structure and gating system optimization

- Mold temperature and cooling control

- Material and process parameters

Mold exhaust design

The formation of bubbles is usually related to the retention of gas inside the mold.

In mold design, a reasonable exhaust system such as exhaust grooves and overflow ports can effectively discharge gases in the mold and reduce the formation of bubbles.

For example, Haichen can reduce air bubbles by improving mold exhaust and cleaning materials, while optimizing the gating system can also reduce air bubbles.

Mold structure and gating system optimization

The structural design of the mold (e.g., gating system, cooling system) affects the flow and solidification process of the metal liquid.

In addition, Haichen reduces the formation of air bubbles by optimizing the mold design, such as optimizing the gating system and cooling system.

Mold temperature and cooling control

In addition, mold temperature and shutdown time also have an impact on the generation of bubbles, and reducing the mold temperature can reduce bubbles.

In mold design, Haichen believes that proper temperature control such as the design of the cooling system can significantly reduce the formation of bubbles.

Material and process parameters

Mold design also needs to consider material selection and process parameters (such as pouring speed, temperature).

Ways to reduce air bubbles include adjusting mold temperature and release agent usage.

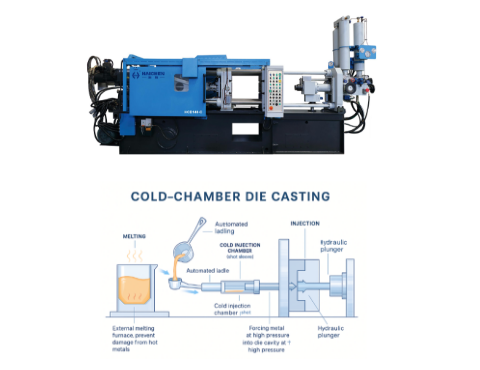

The source of gas in die-casting materials

- The raw material itself contains hydrogen

- Gas absorption during the smelting process

- Coiled gas in the die casting process

- Gases from the decomposition of the release agent

- Coating performance

- Mold and injection chamber

The raw material itself contains hydrogen

The hydrogen in the raw material can be absorbed by the molten metal through water vapor or moist air in the atmosphere, thus forming pores during the solidification process.

Gas absorption during the smelting process

During the smelting process, the molten metal comes into contact with the air and absorbs moisture, nitrogen and other gases in the air.

In addition, rust in the charge, damp mulching agents, refining agents, and fluxes can also cause the molten metal to absorb gases.

Coiled gas in the die casting process

In the high-pressure and high-speed filling process, if the flow of molten metal is not smooth, eddy currents will be generated, resulting in gas being rolled into the molten metal.

Poorly designed gating systems (e.g., sharp corners or dead zones) and poorly set up exhaust and overflow grooves can increase the risk of entrapment.

Gases from the decomposition of the release agent

The release agent decomposes at high temperatures to produce gases that can be absorbed by the molten metal and form pores during solidification.

Coating performance

When the amount of gas in the coating is large, it will also produce gas in the die-casting process, which will affect the product quality.

Mold and injection chamber

The design of the mold cavity and injection chamber is unreasonable, such as poor air permeability, poor exhaust, etc.

Which will also lead to the inability of gas to be discharged in time and the formation of poress.

Haichen‘s suggestions for preventing blisters

- Mold heating and drying control

- Automatic demolding agent spraying

- Pre-delivery non-destructive testing

- Conclusion

Mold heating and drying control

Haichen suggests that manufacturers strictly control the mold temperature and ensure uniform preheating.

All molds and tools are thoroughly dehydrated before use to eliminate the risk of water vapor bubble formation.

Automatic demolding agent spraying

The automated robot system used by Haichen for spray application of mold release agents can ensure precise spraying, with minimal usage and uniform coverage, preventing excessive residual gas in certain areas.

Conclusion

By means of reasonable design, precise control and standardized operation, bubble defects in aluminum alloy die-cast parts can be completely avoided.

As an experienced manufacturer of pressurized casting machines and molds, Haichen provides solutions to various problems for its customers.

Contact us immediately to learn how to optimize your next aluminum die-casting project.

The influence of exhaust system design on blisters in die casting

- The rationality of exhaust system design

- Selection of exhaust method

- Maintenance of the exhaust system

- Optimization of exhaust system

- Innovation of exhaust system

The rationality of exhaust system design

The design of exhaust system directly affects the efficiency of air bubble discharge.

If the exhaust system is not properly designed, such as insufficient exhaust holes, blockage or poor location.

The gas will not be able to discharge smoothly, resulting in the formation of bubbles inside the product.

For example, in mold venting, the vent channel should be designed to ensure that the gas can be discharged smoothly and avoid melt overflow.

Selection of exhaust method

Different exhaust methods have different effects on air bubbles.

For example, natural venting is simple but time-consuming, manual venting requires accurate positioning, and vacuum filling requires specialized equipment and high cost.

Although the vacuum pumping method is completely effective, it requires specialized equipment and technology.

In addition, the vibratory venting method is suitable for small bubbles and is simple to operate with moderate force.

Maintenance of the exhaust system

Regular inspection and maintenance of the exhaust system is key to reducing air bubbles.

For example, a poor design of the exhaust system of a cooling system or a blockage of the exhaust channel can lead to defects such as bubbles, scorching, etc.

Regular cleaning and maintenance of the exhaust system to prevent the exhaust channel from clogging can effectively reduce the generation of air bubbles.

Optimization of exhaust system

By optimizing the design of the exhaust system, such as increasing the number and size of exhaust grooves.

By reasonably setting the location and size of gates, engineers can improve exhaust efficiency and reduce bubble formation.

For example, in mold design, positioning the vent groove at the end of the flow ensures smooth gas discharge.

Innovation of exhaust system

The application of modern exhaust design methods such as 3D printing technology can arbitrarily construct the internal pores of the material.

And the design of free interlacing with the waterway does not interfere with each other, so as to improve the exhaust efficiency.