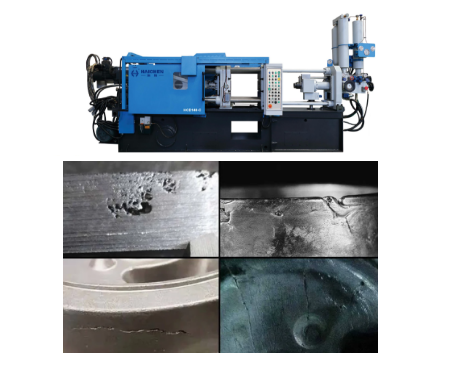

Porosity in die casting is primarily caused by trapped air or gas within the mold cavity, improper gating and venting designs, insufficient compaction of the molten metal, and variations in the injection process such as speed and pressure.

Die casting is a highly efficient manufacturing process used to produce complex metal parts with tight tolerances. However, one of the most common defects encountered in die casting is porosity.

Porosity refers to the presence of small voids or cavities within the casting, which can significantly affect the part’s mechanical properties, corrosion resistance, and overall quality.

Understanding the causes of porosity is crucial for manufacturers to optimize their processes and produce high-quality castings.

Gas Porosity

Gas porosity is one of the primary causes of defects in die castings. It occurs when air or gas becomes trapped within the molten metal during the injection process. This can happen due to several reasons:

- Insufficient Venting: If the die cavity is not properly vented, air can become trapped and form bubbles within the casting. Effective venting systems are essential to allow air to escape as the metal fills the cavity.

- High Injection Speed: While high injection speeds are often necessary to fill the die quickly and avoid solidification, they can also increase the risk of entrapping air. Optimizing injection speed is a delicate balance between filling efficiency and minimizing porosity.

- Poor Die Design: Complex geometries and narrow sections in the die can create turbulence in the molten metal, leading to air entrapment. Proper die design, including the use of runners and gates, can help guide the metal smoothly into the cavity.

Beyond vent design, optimizing the injection profile is crucial to avoid air entrapment. An ideal profile uses multi-stage “slow-fast-slow” control: an initial slow phase lets metal cover the gate smoothly and push air out through the vents; a subsequent high-speed phase ensures rapid cavity fill; a final deceleration phase at the end of fill reduces turbulence from metal impacting the cavity walls. The closed-loop, real-time control of HAICHEN die casting machines can precisely execute such complex profiles, providing direct process assurance to reduce gas porosity.

Shrinkage Porosity

Shrinkage porosity occurs when the molten metal solidifies and contracts, creating voids within the casting. This type of porosity is often more difficult to detect because it can occur deep within the part. Factors contributing to shrinkage porosity include:

- Inadequate Metal Supply: If the die is not adequately filled with molten metal, shrinkage cavities can form as the metal cools and contracts. Ensuring a sufficient supply of metal and optimizing the gate design are critical for preventing this issue.

- Non-Uniform Cooling Rates: Different sections of the casting may cool at different rates, leading to uneven solidification and shrinkage porosity. Using cooling channels in the die to control the cooling rate can help mitigate this problem.

Material Contamination

The presence of impurities or foreign materials in the molten metal can also contribute to porosity. Contaminants can create gas pockets or disrupt the solidification process, leading to voids. Proper material handling and purification processes are essential to ensure the metal is free from contaminants.

Die Maintenance

The condition of the die itself can significantly impact the quality of the casting. Worn or damaged dies can create areas where air becomes trapped or where metal flow is disrupted. Regular maintenance and inspection of the die are crucial for maintaining consistent casting quality.

Die Maintenance & HAICHEN’s Proactive Service Support

The condition of the die is dynamic, and its maintenance quality directly determines the porosity level in long-term production. Worn venting channels, damaged cooling lines, or slightly deformed cavity surfaces can become new sources of porosity. HAICHEN provides not only equipment but also proactive die maintenance support services focused on porosity prevention. Helping customers maintain their dies in optimal condition throughout the production lifecycle.

- How Die Condition Affects Porosity

- HAICHEN’s Preventive Maintenance and Remote Monitoring

- Case Study: Solving Recurring Porosity Through Systematic Maintenance

How Die Condition Affects Porosity

A die degrades with use, and specific changes can trigger porosity:

- Clogged or Worn Venting Systems: Vent slots on the parting line or ejector pins can easily get blocked by release agent residue or aluminum slag, or become worn and oversized from metal erosion. This reduces venting efficiency, trapping gas that forms pores.

- Scaled or Leaking Cooling Channels: Mineral deposits from cooling water build up over time, reducing flow and causing uneven die cooling, which worsens shrinkage porosity. Leaks in water line connections directly lead to loss of temperature control.

- Damaged Cavity Surfaces: Minor sticking or scratches can disrupt smooth metal flow, creating turbulence that traps air or affects the even application of release agent.

HAICHEN’s Preventive Maintenance and Remote Monitoring

HAICHEN‘s after-sales service goes beyond traditional repair, focusing on preventive solutions:

- Scheduled Maintenance Plans & Training: HAICHEN engineers develop customized die maintenance schedules based on machine production data (e.g., shot count) and specific part processes. This includes tasks like vent cleaning, cooling line backflushing, and critical dimension checks, supported by on-site operator training.

- Remote Diagnostics & Data Tracking: For HAICHEN machines with smart interfaces, our service team can remotely access authorized, die-related process data (like peak injection pressure or clamping force curves per shot). Analyzing long-term trends in this data helps predict potential die wear or alignment issues, allowing for early warning before major porosity problems occur.

- Rapid Response & Genuine Parts Support: When a die needs professional repair, HAICHEN can coordinate with expert mold repair resources and supply original-quality spare parts (like specific ejector pins or cooling connectors) to ensure performance is fully restored.

Case Study: Solving Recurring Porosity Through Systematic Maintenance

A customer producing aluminum housings for the telecom industry began experiencing random porosity in a fixed area after about 200,000 shots. The defect rate slowly increased over time. The HAICHEN service team first conducted a thorough die inspection instead of immediately changing process parameters. They found the deep-cavity vent slots in that area were severely clogged, and the flow in adjacent cooling channels had dropped by about 40%. After guiding the customer through a complete vent cleaning and cooling line chemical descaling process, production resumed. Without changing any die casting parameters, the porosity in that area disappeared, and the die returned to a stable state. This case shows that systematic die maintenance is itself one of the most effective process optimizations.

How HAICHEN Die Casting Machines Can Help

HAICHEN, a leading manufacturer of die casting machines, offers advanced solutions to help minimize porosity in die castings. Our machines are designed with state-of-the-art technology to optimize injection speed, pressure control, and cooling efficiency. HAICHEN’s commitment to precision engineering ensures that their machines provide the highest level of control over the casting process. Reducing the risk of porosity and other defects.

HAICHEN: Your Comprehensive Process Support Partner Beyond Equipment

HAICHEN provides data-driven, proactive after-sales support to prevent porosity at the source. For example, while a customer was producing large heat sinks for 5G base stations, our remote monitoring detected a gradual drop in mold cooling efficiency. We gave an early warning and guided preventive maintenance. We also fine-tuned the injection parameters based on long-term production data. This helped keep the product yield stable above 99.5% and boosted overall output by over 15%. This shows HAICHEN is more than an equipment supplier; we are a long-term partner in ensuring sustained, high-quality production.

By understanding the causes of porosity, manufacturers can significantly improve the quality and reliability of their die cast products.