To reduce porosity in die casting through the systematic integration of process parameter optimization, mold venting design, vacuum/degassing technology, and numerical simulation.

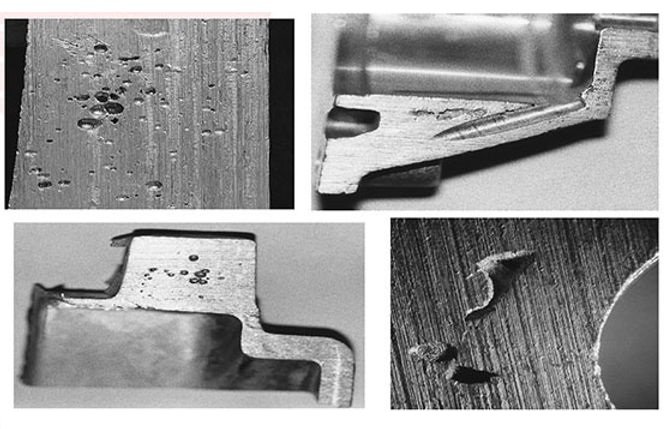

Reducing porosity in die casting is crucial for improving the mechanical properties and surface finish of the final product.

Through the systematic integration of process parameter optimization, mold venting design, vacuum/degassing technology, and numerical simulation, porosity can be significantly reduced in various types of die-cast components, thereby enhancing strength, sealing performance, and overall quality. Steps to reduce porosity in die casting:

- Temperature and Pressure Control

- Material Selection and Degassing

- Advanced Casting Techniques

- Process Simulation and Optimization

Methods to reduce porosity in die castings can start from a number of aspects such as design, optimization of process parameters and material treatment. The following are some specific measures:

Temperature and Pressure Control

- Uniform Temperature Maintenance

- Efficient Cooling Systems

- Metal Temperature

- High-Pressure Injection

- Venting and Mold Design

Uniform Temperature Maintenance

Keeping a consistent temperature throughout the die casting process with advanced die casting techniques helps prevent hot spots and uneven cooling, which can cause shrinkage porosity.

Efficient Cooling Systems

Using chillers and managing differential cooling can ensure even cooling rates, reducing the risk of porosity.

Metal Temperature

Ensuring the molten metal is at the correct temperature before casting prevents the formation of bubbles that can become trapped during solidification.

High-Pressure Injection

Faster and stronger injection speeds can help reduce air bubbles in the casting, especially during the semi-solid stage of solidification.

- Pressure During Solidification: Applying high working pressure of the die casting machine working during solidification process can fill voids as they develop, reducing shrinkage porosity.

- Pressure Release Monitoring: Monitoring pressure release with a pressure gauge and switch can detect irregularities and ensure uniform pressure throughout the process.

Venting and Mold Design

- Proper Venting: Correctly sized, numbered, and located vents ensure that air can escape the die cavity efficiently, preventing gas bubbles from becoming trapped.

- Mold Design: Avoiding sharp corners and complex shapes in mold design can reduce turbulence and the risk of porosity.

- Cooling Systems: Effective cooling systems with uniform cooling rates help minimize shrinkage porosity.

Material Selection and Degassing

- High-Quality Alloy

- Degassing Techniques

- Melting Process Control

High-Quality Alloy

Choosing alloys with high purity and low levels of impurities reduces the risk of gas formation during solidification.

Degassing Techniques

Adding degassing agents to the alloy and filtering it before casting can remove impurities and gases that lead to porosity.

Melting Process Control

Precise temperature control during the melting process, using induction melting systems, helps reduce gas-related porosity.

Advanced Casting Techniques

- Vacuum-Assisted Die Casting

- Controlled Atmosphere Casting

Vacuum-Assisted Die Casting

Applying vacuum pressure during the casting process minimizes gas entrapment and improves metal flow, reducing porosity.

Controlled Atmosphere Casting

Filling the mold with an inert gas like nitrogen before injecting molten metal prevents air ingress, reducing gas porosity.

Process Simulation and Optimization

- Analytical Design Software

- Regular Maintenance

- Quality Control

Analytical Design Software

Using simulation software like MAGMA to predict and prevent porosity issues before they occur helps optimize the placement of gates, vents, and cooling channels.

Regular Maintenance

Keeping molds clean and ensuring that venting and cooling systems are functioning correctly can help minimize defects.

Quality Control

In-line X-ray inspection and post-casting tests like dye penetration and pressure testing can identify porosity issues early.

By implementing these strategies, manufacturers can significantly reduce porosity in die casting, resulting in higher-quality and more reliable metal components.

Haichen die casting machine supplier

Haichen is a well-known supplier of die casting machines, offering a range of equipment designed for various die casting applications. We provide solutions for both hot chamber and cold chamber die casting processes and auxiliary equipments, catering to industries such as automotive, electronics, and consumer goods.

Key Features of Haichen Die Casting Machines:

High Precision: Advanced control systems ensure precise operation and high-quality castings.

Energy Efficiency: Designed to minimize energy consumption while maintaining high performance.

Durability: Robust construction ensures long service life and reliability.

Versatility: Suitable for a wide range of alloys and casting sizes.

Automation Integration: Compatible with various automation systems to enhance productivity.