Metallic lightweight materials offer several benefits, including improved fuel efficiency, enhanced performance, reduced environmental impact, and increased design flexibility, making them ideal for modern manufacturing applications.

In the die – casting industry, the use of metallic lightweight materials has revolutionized the production of high – quality, efficient, and durable components.

These materials, such as aluminum and magnesium alloys, offer a range of benefits that make them ideal for modern manufacturing processes.

This article will explore the various benefits of metallic lightweight materials and how they contribute to the success of die – casting operations.

By understanding these benefits, manufacturers can optimize their production processes, reduce costs, and enhance the quality and performance of their products.

Weight Reduction of Metallic lightweight materials

Improved Fuel Efficiency: In automotive and aerospace applications, reducing weight directly translates to lower fuel consumption and reduced emissions.

Enhanced Performance: Lighter materials improve acceleration, handling, and overall performance of vehicles and aircraft.

Strength-to-Weight Ratio

High Strength: Despite being lightweight, these materials often have high strength, making them suitable for structural applications.

Durability: They can withstand significant stress and strain, contributing to the longevity and reliability of products.

Corrosion Resistance of Metallic lightweight materials

Longevity: Many lightweight metals, such as aluminum and titanium, have excellent corrosion resistance, which extends the lifespan of components and structures.

Reduced Maintenance: Corrosion-resistant materials require less maintenance and fewer replacements, lowering long-term costs.

Thermal and Electrical Conductivity

Efficient Heat Dissipation: Metals like aluminum and copper are excellent conductors of heat, making them ideal for heat exchangers and electronic components.

Electrical Conductivity: These materials are also good conductors of electricity, essential for electrical and electronic applications.

Recyclability of Metallic lightweight materials

Sustainability: Lightweight metals are highly recyclable, contributing to environmental sustainability and reducing the need for virgin material extraction.

Cost-Effective Recycling: The recycling process for metals like aluminum is energy-efficient and cost-effective, making it an attractive option for sustainable manufacturing.

Design Flexibility of Metallic lightweight materials

Versatility: These materials can be easily molded, extruded, and machined into complex shapes, allowing for innovative and efficient designs.

Integration: They can be combined with other materials to create composites with enhanced properties.

Economic Benefits

Cost Savings: Although some lightweight metals may have higher initial costs, the overall savings from reduced fuel consumption, lower maintenance, and longer lifespan can be significant.

Market Competitiveness: Companies using lightweight materials can offer more efficient and high-performance products, gaining a competitive edge in the market.

Safety

Crashworthiness: In automotive applications, lightweight metals can be engineered to absorb impact energy effectively, enhancing passenger safety.

Structural Integrity: High-strength lightweight materials maintain structural integrity under extreme conditions, crucial for aerospace and construction applications.

Environmental Impact

Reduced Emissions: Lower weight leads to reduced greenhouse gas emissions, contributing to environmental protection.

Energy Efficiency: The production and recycling processes for many lightweight metals are energy-efficient, further reducing their environmental footprint.

Innovation and Advancements

Research and Development: Ongoing advancements in metallurgy and material science continue to improve the properties and applications of lightweight metals.

New Applications: These materials are enabling new technologies and applications, such as electric vehicles and advanced aerospace systems.

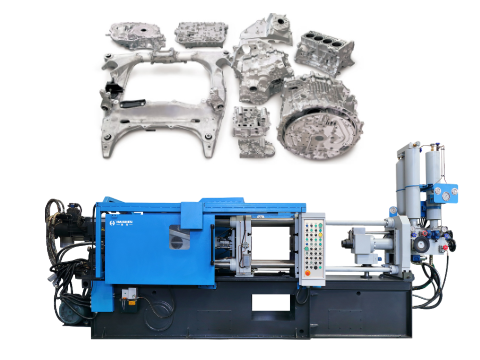

Haichen die casting machine supplier

Haichen is a well-known Chinese manufacturer specializing in die casting machines. We offer a wide range of die casting equipment, including cold chamber die casting machines, hot chamber die casting machines and auxiliary equipments.

Our die casting machines are designed to work with these Metallic lightweight materials.

If you need further clarification or specific details about Haichen’s machines or lightweight material applications, feel free to ask.