Die casting used reason includes efficient production of parts with complex geometries, suitable for mass production and so on.

Why die casting is used? Because die casting is an efficient metal casting process that can produce metal parts with complex geometries and precise dimensions. This process uses high pressure to inject molten metal into a mold, which is usually made of hardened tool steel and can be reused to achieve high precision and consistency.

We will analyze this topic mainly from below six aspects:

- Efficient production of parts with complex geometries

- Suitable for mass production

- Diverse material selection

- High surface quality and dimensional accuracy

- Reduced need for subsequent processing

- Lightweight and cost-effective

- Environmental protection and recyclability

The reasons why die casting is widely used mainly include the following:

Efficient production of parts with complex geometries

Material and Process Selection

Non-ferrous alloys such as aluminum, zinc, and magnesium can be injected into the mold under high pressure to achieve complex features such as thin walls, sharp corners, and internal cavities.

For extremely small or high-precision parts, high pressure die casting (HPDC) or multi-slide die casting can improve fill integrity and dimensional accuracy while maintaining high production speeds.

Mold Design and Processing

CNC machining (CNC) and electrical discharge machining (EDM) are key technologies for achieving fine features and difficult-to-machine areas. They can directly form structures such as fine walls, chamfers, and internal channels on the mold.

Multi-slide molds increase mold flexibility by increasing the number of slides, allowing internal structures, thin walls, and complex contours to be formed in a single step, significantly reducing the need for secondary machining.

Mold preheating and uniform temperature control reduce thermal shock, ensure that the molten metal fully fills the details, and minimize defects.

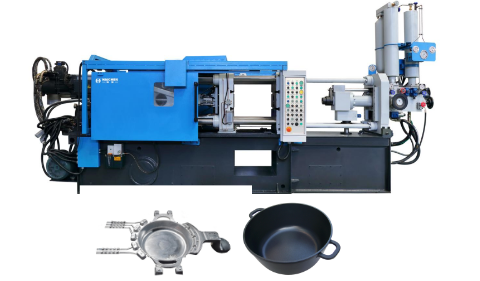

For example, Haichen adpot high-pressure die casting (HPDC) to produce high-quality aluminum alloy cookware pots with exceptional efficiency and performance.

By injecting molten aluminum into precision steel molds under intense pressure, this process enables the rapid production of pots with complex, thin-walled geometries and excellent dimensional consistency. The result is lightweight yet durable cookware with superior heat distribution.

Key advantages include high production speeds, minimal material waste, and the ability to integrate reinforced structures and intricate surface details directly into the casting, ensuring both functional excellence and aesthetic appeal in every piece.

Haichen die casting machine company can also produce replaceable pot bottom moulds for same diameter with different bottom shape pans. That can help save and reduce customer’s significant cost.

Gating System and Runner Design

Rational layout of gates, runners, and venting systems ensures that metal quickly and evenly fills the entire cavity under high pressure, especially for thin walls and long, narrow channels.

Use simulation software (such as flow analysis and thermal analysis) to pre-evaluate filling behavior, optimize pouring parameters, and avoid defects such as cold shuts and porosity.

Process Parameter Control

Injection pressure, holding time, and cooling rate are key parameters determining filling integrity and dimensional stability. High-pressure injection overcomes resistance in complex geometries, while the holding phase ensures metal shrinkage compensation and rapid cooling improves production cycle times.

Use specialized melting and alloying formulas for different alloys to enhance fluidity and strength, meeting lightweight and high-strength requirements.

Suitable for mass production

Die casting is particularly suitable for mass production of small to medium-sized castings. Its unit cost is low and suitable for large-scale production.

High-pressure die casting, combined with low-melting-point alloys (aluminum, magnesium, and zinc) and high-strength mold steel, is the optimal process for producing high-quality metal parts at a low cost and in large quantities.

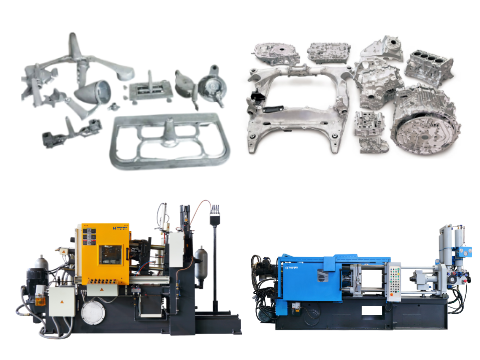

Automotive lightweight structural parts

Engine mounts, door inner panels, headlight housings (aluminum/magnesium alloys).

Consumer electronic product housings

Mobile phone, tablet, and laptop radiators (zinc alloys).

Industrial connectors

Gears, nuts, and valve bodies (zinc/aluminum alloys).

For example, Haichen die casting machine company uses aluminium alloy material(ADC13), design with 12cav multi-cavity molds to produce aluminium cookware handles. With Haichen advanced die casting techniques , that can meet customer’s high output mass production requirements.

Aerospace lightweight components

High-strength magnesium alloy chassis and structural parts.

Technical advances such as multi-cavity molds, rapid cooling, and automated production lines can further increase production capacity to meet the scale-up demands of industries such as automotive, electronics, and aviation.

Diverse material selection

Die casting can use a variety of non-ferrous metals. Such as zinc, aluminum, copper, magnesium, etc. Among which aluminum alloy and zinc alloy are the most commonly use materials. These materials have good mechanical properties and processing properties.

For example, aluminum alloy is light and corrosion-resistant, and zinc alloy has good fluidity and a low melting point.

Density and Weight

- For lightweighting requirements (automotive, aviation), aluminum or magnesium alloys are preferred.

- For applications requiring high strength but not weight, copper alloys can be considered.

Strength and Hardness

- For components requiring high strength and wear resistance (gears, valve bodies), high-silicon aluminum alloys (A380) or heat-treated aluminum alloys (A356) are suitable.

- Copper alloys have strength similar to that of steel and are suitable for high-load structural parts.

Thermal Conductivity and Heat Dissipation

For heat sinks and electronic packaging, aluminum alloys (thermal conductivity ≈ 92-96 W/(m·K)) or copper alloys (higher thermal conductivity) are preferred.

Electrical Conductivity

For components requiring good electrical conductivity (contacts, conductive housings), copper or aluminum alloys are preferred.

High surface quality and dimensional accuracy

Due to high-pressure injection and precise mold design, die castings usually have high surface quality and dimensional accuracy, and can even produce parts with a wall thickness of only 0.5 mm.

Reduced need for subsequent processing

Many die castings require no further processing after production, which reduces production costs and increases efficiency.

Lightweight and cost-effective

In the automotive industry, die casting uses to manufacture lightweight components. Such as the rear floor assembly of the Tesla Model Y, which not only reduces weight (by 30%) but also reduces manufacturing costs (by 40%) by using die casting technology.

Environmental protection and recyclability

The materials used in die casting are easy to recycle and meet environmental protection requirements.

Die casting widely uses in many fields such as automobile, aerospace, electronics, agricultural machinery, etc. Due to its high efficiency, low cost, suitability for mass production and ability to manufacture parts with complex geometries.

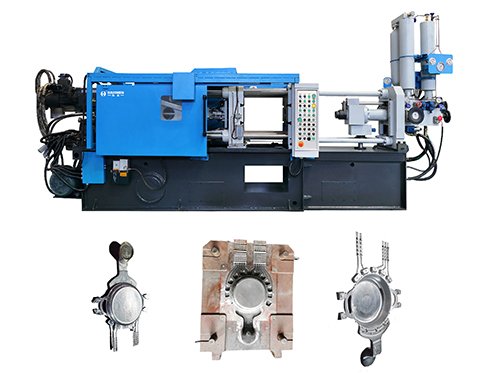

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.