Difference in casting methods: Die casting uses high pressure for detailed parts; centrifugal casting uses rotation for cylindrical shapes.

Die casting and centrifugal casting are both widely used metal casting processes, but they have distinct characteristics, applications, and advantages. Understanding the differences between these two methods is crucial for selecting the appropriate casting technique for specific manufacturing needs.

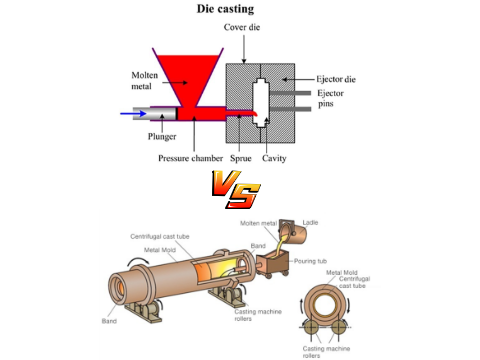

Difference in casting methods:Die Casting

Die casting is a process in which molten metal is forced into a mold cavity under high pressure. The mold, typically made of steel, is designed to produce parts with high precision and complex geometries. The metal solidifies quickly, So that, resulting in a finished part with tight tolerances and excellent surface finish.

- High Production Efficiency: Die casting is ideal for high-volume production runs. The process is fast, with cycle times often measured in seconds, making it highly efficient for manufacturing large quantities of identical parts.

- Precision and Complexity: The use of high-pressure injection allows for the production of intricate designs and thin-walled components. This makes die casting suitable for industries such as automotive, aerospace, and consumer electronics, where precision and detail are critical.

- Material Choices: Common materials used in die casting include aluminum, zinc, magnesium, and copper alloys. These materials offer a range of mechanical properties suitable for various applications.

HAICHEN, a leading die-casting machine manufacturer, specializes in providing advanced die-casting solutions. Our machines are designed to deliver high precision, consistent quality, and reliable performance, making them a preferred choice for manufacturers seeking efficient and high-quality die-casting processes.

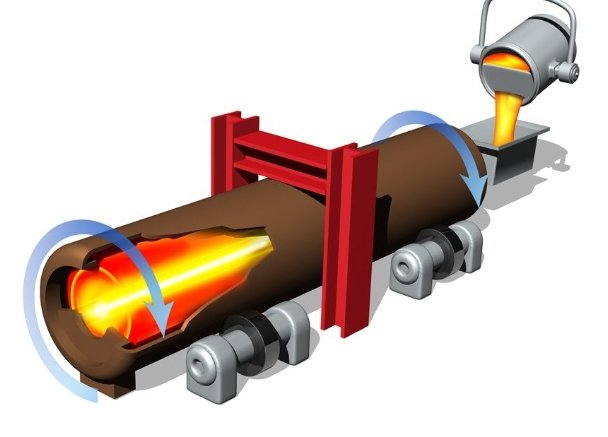

Difference in casting methods:Centrifugal Casting

Centrifugal casting, on the other hand, involves pouring molten metal into a rotating mold. The centrifugal force generated by the spinning mold distributes the metal evenly along the mold’s walls, creating a uniform and dense casting. This process is particularly effective for producing cylindrical or tubular components.

- Structural Integrity: Centrifugal casting is known for producing parts with excellent structural integrity and minimal porosity. The centrifugal force helps to push impurities towards the center, resulting in a dense and strong final product.

- Simplicity and Cost-Effectiveness: The process is relatively simple and can be more cost-effective for certain applications, especially when producing large, simple-shaped components. It is commonly used for manufacturing pipes, flywheels, and other cylindrical parts.

- Material Choices: Centrifugal casting can be used with a variety of metals, including iron, steel, and various alloys. The choice of material depends on the specific requirements of the final product.

Key Difference between the die casting and centrifugal casting

| Feature | Die Casting | Centrifugal Casting |

| Production Volume | High-volume production | Suitable for medium to large components |

| Complexity | High precision, complex geometries | Simple, cylindrical shapes |

| Cycle Time | Fast, measured in seconds | Slower, depending on part size |

| Surface Finish | Excellent, with tight tolerances | Good, but may require additional machining |

| Structural Integrity | High strength, but may have porosity in complex parts | Excellent, dense structure with minimal porosity |

| Cost | High initial cost for tooling | Lower tooling cost, but higher per-unit cost |

Choosing the Right Process

Selecting the appropriate casting method depends on the specific requirements of the project. Die casting is ideal for high-volume production of complex, precision parts with tight tolerances. Centrifugal casting, on the other hand, is best suited for producing large, simple-shaped components with excellent structural integrity.

Difference in casting methods highlights that die casting and centrifugal casting are both valuable metal casting processes, each with its own set of advantages and applications. By understanding these differences, manufacturers can make informed decisions to optimize their production processes and achieve the desired outcomes.