Die casting technology is a manufacturing process used to produce metal parts with high precision and excellent surface finish.

Die casting is a manufacturing process that forces molten metal under high pressure into reusable metal molds (dies). It can produce complex, thin-walled, and high-strength metal parts with close tolerances.

Haichen upholds its proprietary high-quality die-casting technology, setting new standards in metal manufacturing and achieving industry-leading precision to deliver the highest performance.

Key Components of die casting technology

Die: The mold used in the process. It consists of two halves that come together to form the shape of the desired part.

Metal Alloy: Commonly used materials include aluminum, zinc, magnesium, and copper-based alloys. The choice of alloy depends on the required properties of the final product, such as strength, weight, and corrosion resistance.

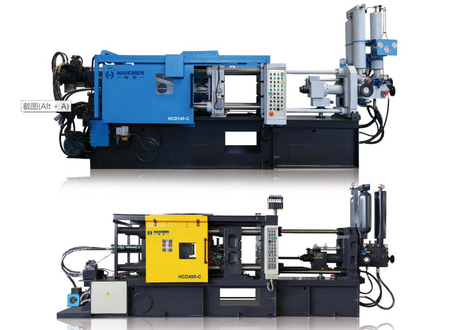

Die Casting Machine: This is the equipment that holds the die, injects the molten metal, and applies pressure. It can be either a hot chamber machine (suitable for low-melting-point metals like zinc) or a cold chamber machine (used for metals with higher melting points like aluminum).

Types of Die Casting

Hot Chamber Die Casting: Used for metals with low melting points, such as zinc and magnesium. The injection mechanism is submerged in the molten metal.

Haichen’s hot-chamber die-casting machines feature an ingenious design, enabling the production of intricate zinc alloy and lead alloy components, as well as decorative items.

Cold Chamber Die Casting: Suitable for metals with high melting points, such as aluminum and copper. The molten metal is poured into a cold chamber before being injected into the die.

Haichen’s large-tonnage cold die-casting machines provide proven solutions for the production of large-scale aluminium alloy radiators, automotive components, road infrastructure, and LED stud lighting products worldwide.

Process Steps of die casting technology

Preparation: The operator applies a lubricant to the die to prevent sticking and to control the temperature, then closes the two halves of the die.

Injection: The die casting machine injects molten metal into the die at high speed (usually between 100 and 150 meters per second) and high pressure (ranging from 10 to 175 megapascals).

Solidification: The molten metal rapidly cools and solidifies within the die. The cooling time depends on the thickness of the part and the type of metal used.

Ejection: Once the metal has solidified, the operator opens the die and ejects the casting using ejector pins.

Trimming and Finishing: Any excess material such as flash or runners is removed. The part may then undergo further processing like machining, plating, or painting.

Applications:

Die casting is widely used in various industries, including:

Automotive: Engine components, transmission housings, and structural parts.

Consumer Electronics: Housings for devices, heat sinks, and connectors.

Aerospace: Lightweight components with high strength.

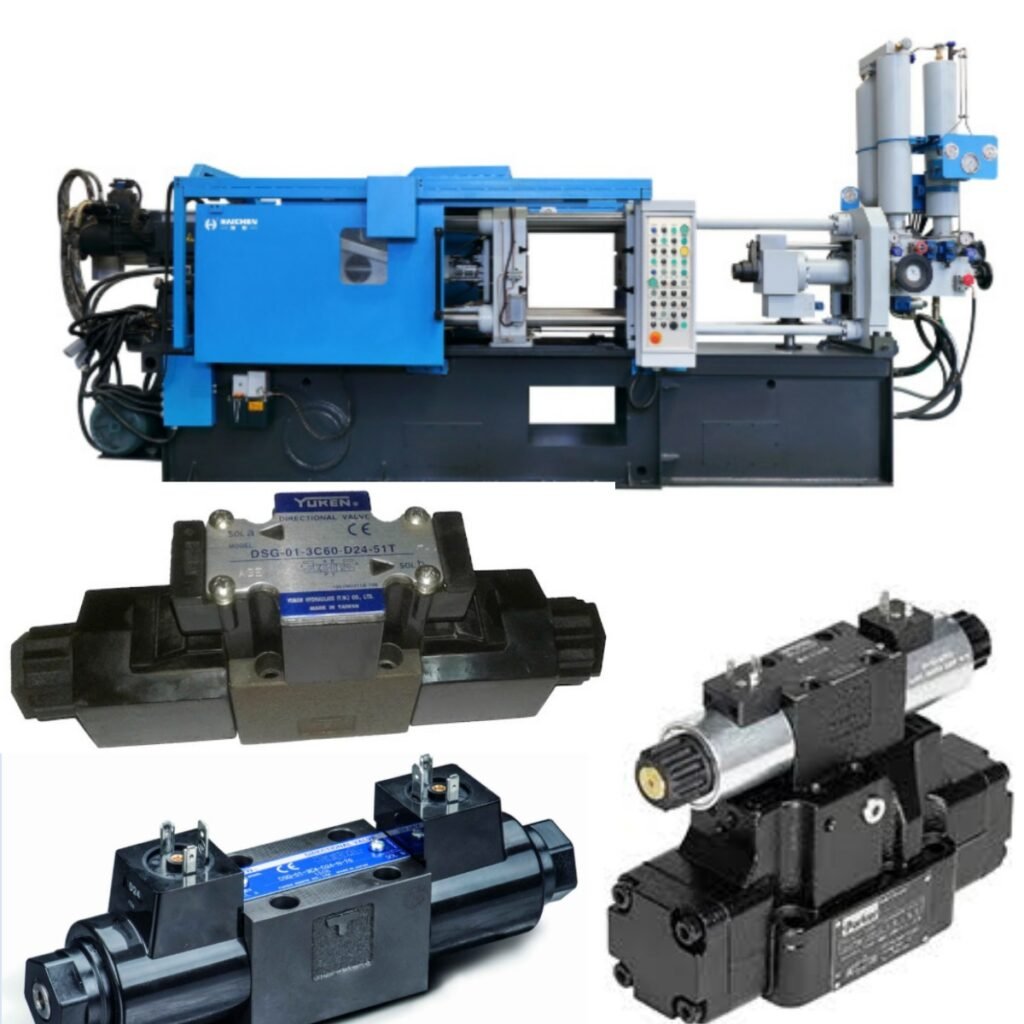

Industrial Equipment: Pumps, valves, and machinery parts.

Haichen die casting machine supplier

Haichen is a well-known Chinese manufacturer and supplier of die casting machines. The company specializes in producing a wide range of die casting equipment, including cold chamber die casting machines, hot chamber die casting machines, and auxiliary equipments.

Key Features of Haichen Die Casting Machines

High Precision: Haichen machines are designed to deliver high precision and consistency in die casting operations.

Energy Efficiency: The company focuses on energy-saving technologies to reduce operational costs.

Advanced Control Systems: Haichen machines often come equipped with sophisticated control systems for better automation and process control.

Durability: Built with high-quality materials, Haichen machines are known for their durability and long service life.

Customization: The company offers customizable solutions to meet specific customer requirements.