Choose cold die casting material includes mechanical properties of materials, production cost and demand, product design and so on.

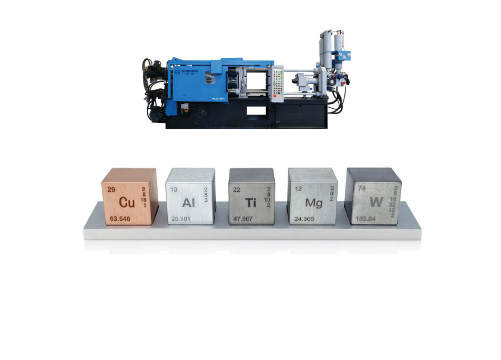

Selecting materials suitable for cold chamber die casting requires comprehensive consideration of multiple factors, including the material’s mechanical properties, production costs, production requirements, product design, environmental factors, and sustainability.Aluminum, copper, magnesium and zinc are common cold chamber die casting materials, and the specific selection should be optimized according to the actual application scenario and requirements.

We will analyse how to choose the right materials for cold die casting from below aspects:

- Mechanical properties of materials

- Production cost and production demand

- Product design

- Environmental factors

- Sustainability

- Production efficiency

Choosing well helps your production be efficient and your product be high quality.

Mechanical properties of materials

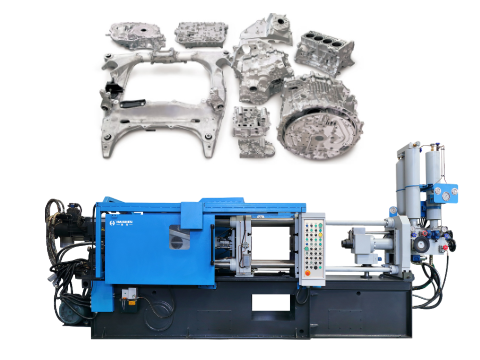

Cold chamber die casting is suitable for the use of high melting point metals such as aluminum, copper and their alloys, which have good strength, toughness and durability.

They can withstand the high pressure and high temperature during the cold chamber die casting process.

In addition, light metals such as magnesium and zinc also commonly use in cold chamber die casting because they have lower density and higher corrosion resistance.

- Understanding Core Mechanical Properties

- Matching Materials to Application Demands

- Optimizing for Performance and Cost-Efficiency

Understanding Core Mechanical Properties

- Choosing the right material for cold chamber die casting begins with a deep understanding of the core mechanical properties that define a part’s function and longevity. The primary considerations are tensile strength and yield strength, which determine how much load a component can withstand before deforming or failing.

- For parts under constant stress, fatigue strength is equally critical, as it measures resistance to failure under repeated loading cycles. Additionally, elongation, or ductility, indicates the material’s ability to stretch or bend without cracking—a vital property for components that may experience impact or require secondary bending operations.

- These fundamental properties form the baseline for any material selection decision in engineering-driven applications.

Matching Materials to Application Demands

- Once key properties are identified, the next step is matching them to specific application demands through proven die-casting alloys.

- For the vast majority of structural, lightweight components, aluminum alloys like A380 and ADC12 are the premier choice. They offer an optimal balance of good tensile strength, excellent corrosion resistance, and impressive fluidity for casting complex shapes. When the highest strength-to-weight ratio is paramount, such as in aerospace or portable electronics, magnesium alloys (e.g., AZ91D) are superior, though they require more process control.

- For applications demanding exceptional thermal/electrical conductivity, wear resistance, or antimicrobial properties, copper alloys (like brass) are selected, despite their higher casting temperatures and cost.

Optimizing for Performance and Cost-Efficiency

- The final selection must optimize the trade-off between mechanical performance, manufacturability, and total cost. A material with excessively high strength may be unnecessary and could increase cycle times or require more expensive tooling.

- Consider the complete lifecycle: a slightly more expensive alloy with better corrosion resistance may eliminate the need for a secondary coating, saving long-term costs. Furthermore, the chosen alloy must exhibit excellent castability—including low hot cracking tendency and minimal shrinkage—to ensure high production yield and consistent quality.

- Ultimately, the right material is one that not only meets the mechanical specifications but also aligns with economical, high-volume production in the cold chamber die-casting process.

Production cost and production demand

- Aligning Material Choice with Production Demand Volume

- Analyzing the Total Production Cost Equation

- Balancing Performance, Demand, and Economics

When choosing materials, you need to balance cost and quality. For example, aluminum widely uses in automotive parts due to its high strength and lightweight properties. But its cost is high; while zinc and magnesium widely use due to their lower cost and good mechanical properties.

Aligning Material Choice with Production Demand Volume

- The scale of your production demand is the primary driver for material selection in cold die casting. For high-volume runs (hundreds of thousands to millions of parts), the focus shifts to maximizing throughput and minimizing cost per unit.

- In these scenarios, highly castable alloys like A380 aluminum are favored for their excellent fluidity and shorter cycle times, which directly boost output.

- For low to medium-volume or specialized production, there is greater flexibility to select higher-performance or niche alloys (e.g., magnesium for extreme lightweighting) even if they are slower to cast, as the total material cost impact is less significant and justified by the part’s premium value.

Analyzing the Total Production Cost Equation

- Choosing a material based solely on its per-kilogram price is a common pitfall. A true cost analysis must consider the total production cost, which is heavily influenced by the alloy’s properties.

- A less expensive alloy that causes soldering or die wear increases tooling maintenance costs and downtime. Conversely, a premium alloy with superior fluidity and thermal properties can fill thinner walls, reduce cycle time, and improve yield, lowering the effective cost per part.

- Furthermore, the alloy’s machinability, required finishing processes, and scrap recyclability all contribute to the final landed cost, making a holistic view essential.

Balancing Performance, Demand, and Economics

- The optimal choice strikes a precise balance between the part’s performance requirements, the production demand profile, and overall project economics.

- This involves cross-referencing mechanical needs with commercial realities. For instance, specifying a high-strength alloy for a non-critical component adds unnecessary expense, while under-specifying can lead to field failures and greater cost.

- The goal is to select the most economical alloy that reliably meets all functional and durability specifications for the intended production volume. This balanced approach ensures the final component is not only fit-for-purpose but also produced in a cost-effective, scalable manner for the target market.

Product design

- Design Complexity and Geometrical Demands

- Structural Requirements and Load Conditions

Material selection should be based on the functional requirements of the product. For example, products that require high strength and durability can choose copper or zinc; products that require lightness can choose aluminum or magnesium.

Design Complexity and Geometrical Demands

- The inherent complexity of your product design dictates material selection by demanding specific casting properties. Components with thin walls, intricate details, and deep ribs require an alloy with excellent fluidity to fill the entire mold cavity completely before solidifying.

- Aluminum alloys like A380 are renowned for this property. Designs incorporating internal threads, fine logos, or complex lattices further benefit from an alloy that produces a smooth surface finish and precise dimensional accuracy.

- The material’s ability to replicate the mold’s geometry without defects is paramount, making castability a critical design-driven criterion.

Structural Requirements and Load Conditions

- The functional role of the part fundamentally guides material choice through its required mechanical properties.

- A product design intended for structural or load-bearing applications—such as automotive brackets or housing for power tools—will prioritize materials with high tensile strength, yield strength, and good fatigue resistance. Conversely, a decorative housing primarily needs good surface finish and corrosion resistance.

- The design must also consider potential impact forces, thermal cycling, or exposure to corrosive environments, which will point toward alloys with enhanced ductility, thermal stability, or specific protective oxide layers to ensure long-term durability.

Environmental factors

In the cold chamber die casting process, the corrosion resistance of the material is crucial.

For example, aluminum is prone to oxidation in certain environments, so anti-corrosion measures are required.

Sustainability

Choosing materials with less impact on the environment is a trend in modern manufacturing.

For example, aluminum and magnesium have a high recycling rate, which meets the requirements of sustainable development.

Production efficiency

Cold chamber die casting has a long production cycle, so the selection of materials should take into account its filling and cooling properties in the mold. For example, aluminum and magnesium cool faster, which helps improve production efficiency.

Your project’s budget and how many parts you need matter a lot. Common materials like standard aluminum often cost less. But for very high volume production, a material that casts faster can save total cost. For low volume, you can use special materials. Always think about the total cost, not just the material price. This includes mold wear, finishing work, and material waste.

HAICHEN how to choose the right materials for cold die casting

HAICHEN helps a customer choose materials for a real high pressure die casting application.

- Project Goal and Challenge

- Our Material Selection Process

- Result and Benefit

Project Goal and Challenge

A customer needed to make a new automotive part. The part had to be very strong, quite light, and made in large numbers. The main challenge was finding one material that met all needs for their high pressure die casting application without making the cost too high.

Our Material Selection Process

First, our engineers studied the part’s job. It needed good tensile strength and fatigue strength. Next, they looked at the design. The part had some thin sections, so fluidity was key. Finally, they checked the production plan for high volume. We suggested a modified aluminum alloy. It had the right strength, flowed well for the design, and was cost-effective for large-scale production.

Result and Benefit

The customer used our suggested material. The high pressure die casting application was a success. The parts were strong and passed all quality tests. Production was smooth with few defects. The customer saved money by using an efficient material and made high-quality parts on time. This shows how smart material choice makes a difference.

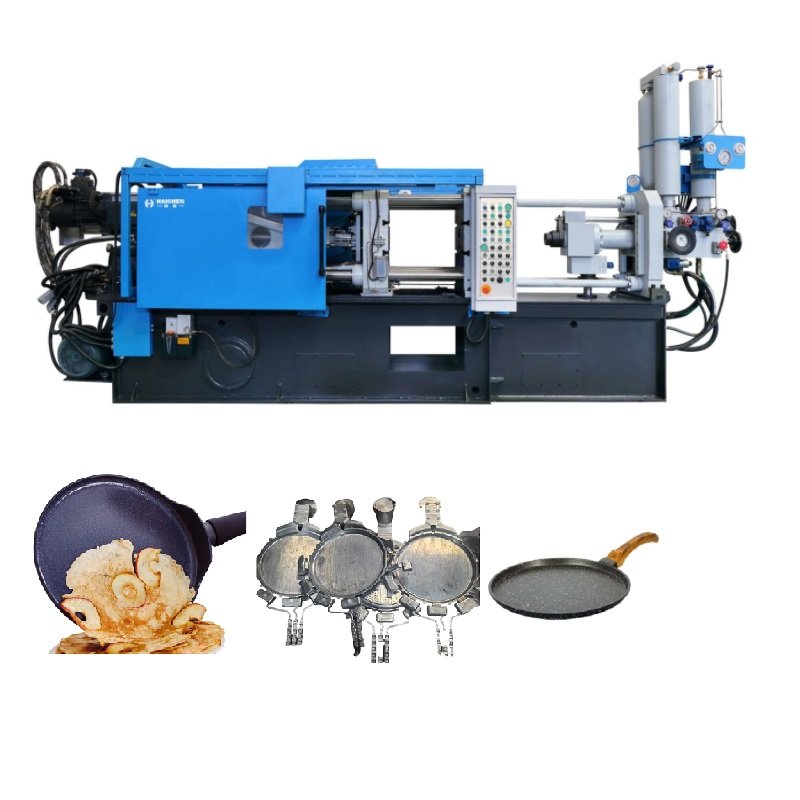

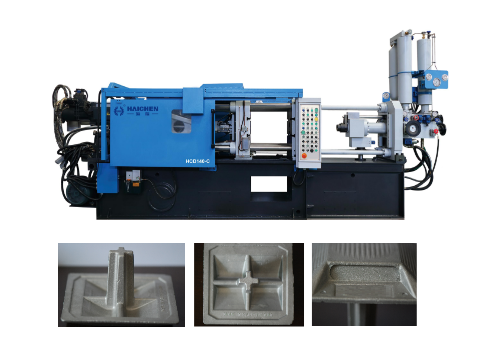

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.