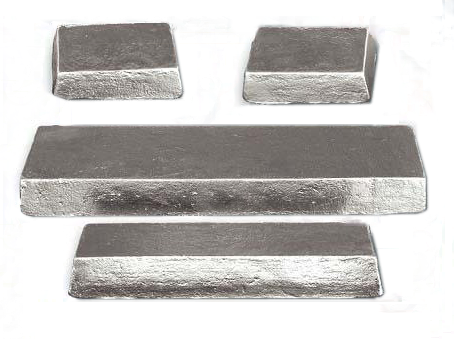

Aluminum alloys, zinc alloys and magnesium alloys as mainly common materials used in high pressure die casting. Sometimes, brass and copper are chosen for special applications needing high strength or corrosion resistance.

In die casting process process matching, the material has hot chamber and cold chamber different production application. Hot-chamber die casting machines are suitable for low-melting-point alloys such as zinc, lead, and tin. Cold-chamber die casting machines are used for high-melting-point alloys, primarily aluminum and magnesium alloys.

High pressure die casting (HPDC) is a versatile manufacturing process that can utilize a variety of materials, primarily metals. The materials are used in high pressure die casting commonly are typically non-ferrous alloys. Due to their favorable properties such as good fluidity, low melting points, and high strength-to-weight ratios. The most commonly used materials include:

- Aluminum Alloys

- Zinc Alloys

- Magnesium Alloys

- Copper Alloys

- Other Materials

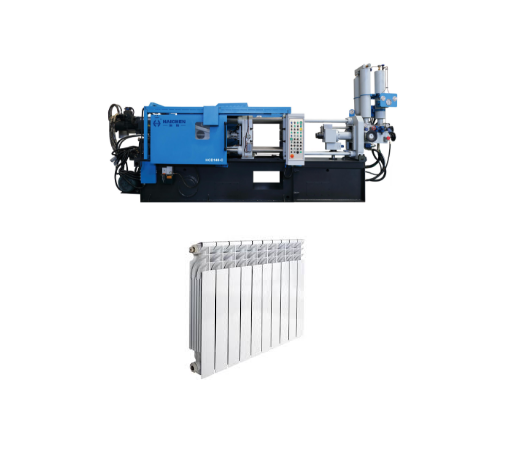

Aluminum Alloys

Advantages

Aluminum alloys are lightweight, have good corrosion resistance, and excellent mechanical properties. They also have a relatively low melting point, which makes them easier to cast.

Applications

Widely used in the automotive industry for engine parts, wheels, and structural components. They are also used in consumer electronics for cases and housings. Haichen popular alumnium alloy die casting product is aluminum radiator.

For example, With aluminum alloys Haichen die casting machine can produce aluminum alloy pot. We can design replaceable pot bottom moulds for same diameter with different bottom shape pans. That can help save and reduce customer’s significant cost.

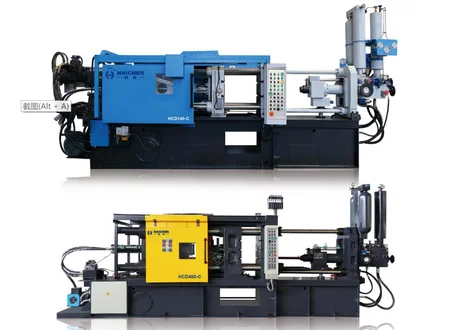

Haichen high pressure die casting machine

Haichen is a well-known manufacturer of high-pressure die casting (HPDC) machines, based in China. The company produces a wide range of die casting machines including cold chamber and hot chamber die casting machines. The machines cater to various industries, including automotive, electronics, home appliances, and more. Haichen’s machines are known for their reliability, efficiency, and advanced technology.

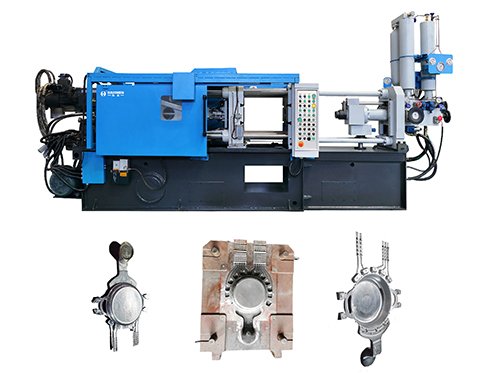

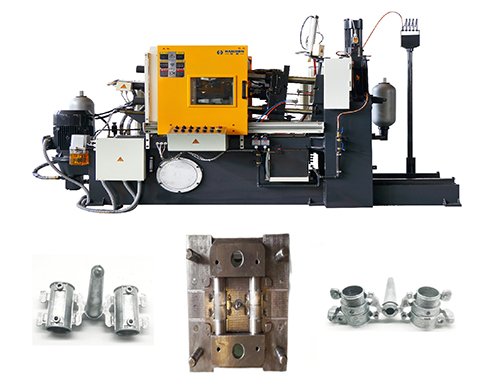

Zinc Alloys

Advantages

Zinc alloys have high strength and hardness, and they can be easily cast into complex shapes with thin walls. They also have good wear resistance.

Applications

Commonly used for small parts such as connectors, fittings, and decorative components. They are also used in the automotive and aerospace industries for certain components. In die casting, Haichen used zinc alloys material to produce medal and zinc alloy pipe fitting coupling .

Key Features of Haichen High-Pressure Die Casting Machines

High Precision and Efficiency:

Haichen machines are designed to deliver high precision in casting, ensuring consistent quality and reducing material waste.

Advanced control systems and automation features enhance production efficiency.

Robust Construction:

The machines are built with high-quality materials to withstand the rigorous demands of high-pressure die casting.

Durable components ensure long service life and reduced maintenance costs.

Magnesium Alloys

Advantages

Magnesium is the lightest structural metal, which makes it ideal for applications where weight reduction is critical. It also has good damping properties.

Applications

Used in the automotive industry for components like engine cradles, transmission cases, and seat frames. It is also used in the electronics industry for portable devices.

Haichen has established a prominent force in the die-casting industry, renowned for providing technologically advanced solutions. Specializing in both hot and cold chamber die-casting machines. For examples, pupular with aluminum pan die casting, aluminium radiator die casting, zinc medal die casting, zinc pipe couping die casting and so on.

Copper Alloys

Advantages

Copper alloys, such as brass and bronze, have excellent electrical and thermal conductivity. They also have good corrosion resistance and high strength.

Applications

Used in electrical connectors, plumbing components, and certain automotive parts. They are also used in marine applications due to their corrosion resistance.

Other Materials

Lead Alloys

Used for radiation shielding and certain types of bearings.

Tin Alloys

Used in applications requiring low melting points, such as certain types of bearings and low-temperature molds.

The choice of material depends on the specific requirements of the application, such as mechanical properties, weight considerations, corrosion resistance, and cost.

Haichen Die Casting Machine

Haichen is one Chinese die casting machine manufacturer for more than 10years.

Key Features of Haichen High-Pressure Die Casting Machines

High Precision and Efficiency:

Haichen machines are designed to deliver high precision in casting, ensuring consistent quality and reducing material waste.

Advanced control systems and automation features enhance production efficiency.

Robust Construction:

The machines are built with high-quality materials to withstand the rigorous demands of high-pressure die casting.

Durable components ensure long service life and reduced maintenance costs.

Energy Efficiency:

Haichen incorporates energy-saving technologies in their machines, reducing power consumption and operational costs.

Features like servo-driven systems optimize energy use during the casting process.

Advanced Control Systems:

Equipped with state-of-the-art PLC (Programmable Logic Controller) systems for precise control over the casting process.

User-friendly interfaces allow for easy operation and monitoring.

Customization Options:

Haichen provides customization options to meet specific customer needs, including tailored machine specifications and additional features.