HPDC molds are primarily made from specialized hardened tool steels like H13, P20, and 420 stainless steel.

HPDC molds material directly affects mold life, production efficiency, and part quality.

The core material of HPDC molds is alloy tool steel, which achieves high heat resistance, wear resistance, and fatigue resistance through precision machining and surface treatment.

Die casting mould material is an essential component of the industrial production process, providing strength, durability, and longevity to finished products.

Haichen‘ll explore the different types of die casting mould material, their benefits, and how to select the right one for your.

The core requirements of the HPDC molds material

In the HPDC process, the mold is subjected to high pressures (10–175 MPa), high temperatures (up to 600–1000°C for molten metal), and repeated thermal shocks.

High thermal strength: resists high temperature softening

Thermal fatigue resistance: Reduces cracks caused by repeated heating and cooling

Abrasion resistance: Resists the erosion of metal flow

Corrosion resistance: Resists chemical attack by molten metal

High thermal conductivity: accelerates cooling to shorten production cycle time

Dimensional stability: ensures part accuracy

Commonly used HPDC molds material types

- Steel H13

- H11 steel

- Dievar Steel

Steel H13

The most widely used die steel containing 5% chromium, 1% molybdenum and 1% vanadium, with excellent thermal fatigue resistance and wear resistance.

The electroslag remelting (ESR) process can improve the homogeneity of the material and reduce internal defects, which is suitable for aluminum and magnesium alloy die casting.

H11 steel

Similar to H13, but with lower carbon content and better toughness, it is suitable for scenarios with higher impact requirements.

Dievar Steel

Improved hot work steel with improved thermal crack resistance through the addition of tungsten and optimized molybdenum/vanadium ratio, resulting in a 20–30% increase in die life compared to H13.

Other alloy steels

- P20 Steel

- 420 Stainless Steel

P20 Steel

A versatile, pre-hardened tool steel, often used for lower-temperature zinc and plastics, offering good machinability.

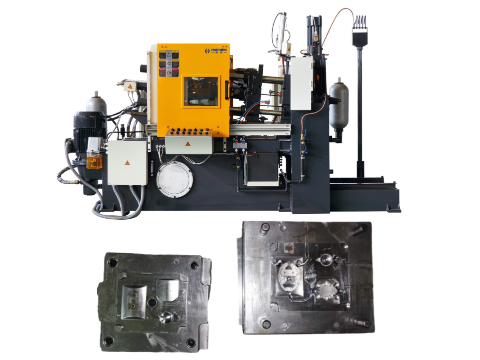

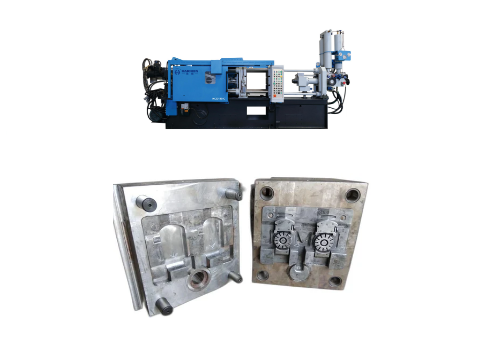

Die casting mould material is a type of metal alloy used to form parts and components for industrial applications.

The material is heated to a molten state and then poured into a mould, where it cools and hardens into the desired object. This process allows for precise shapes and dimensions, as well as strength and durability.

420 Stainless Steel

Offers good corrosion resistance and hardness, suitable for specific applications.

Die casting mould material is often used in the automotive, aerospace, and medical industries, as it can provide superior strength and performance compared to other materials.

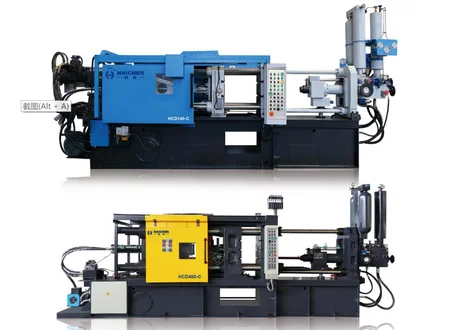

For instance, Haichen has handled cases of die-casting parts such as MEDALS, road studs and door handles.

Advantages of Haichen HPDC molds material

Haichen mould material offers a number of advantages that make it an ideal choice for industrial applications.

It is lightweight and strong, offering superior performance compared to other materials.

It is also highly resistant to corrosion and heat and can be used to produce intricate shapes and components.

Additionally, die casting mould material is relatively inexpensive and can be used for mass production.

Additionally, die casting mould material is highly durable and can withstand high temperatures and pressures without weakening or breaking.

This makes it ideal for applications such as automotive and aerospace components, which must withstand extreme conditions.

Additionally, die casting mould material is generally easier to work with than other materials, and the process of casting it is relatively simple.

HPDC Molds manufacturing and processing technology

- Forging & Heat Treatment

- Surface treatment

- Cooling system design

Forging & Heat Treatment

Staged quenching (e.g. 425°C sectional quenching) can improve impact toughness (up to 26J) and avoid brittleness caused by bainite structure.

Surface treatment

Enhancing wear resistance by nitriding (increasing surface hardness to 1000–1200 HV) or PVD coatings (e.g., CrN, TiAlN) extends mold life by 30–50%.

Cooling system design

Optimize the layout of the internal waterway of the mold, combined with external spray cooling, control the thermal gradient and reduce thermal stress.

Key Performance Requirements for Material Selection

- Thermal fatigue resistance

- High Temperature Strength and Ductility

- Resistance to molten metal erosion

- Ease of processing and maintenance

Thermal fatigue resistance

HPDC molds are subjected to repeated quenching and quenching (molten metal temperatures can reach temperatures above 700°C), resulting in the accumulation of thermal stresses.

Although H13 ESR steel has deep cracks in the thermal cycling test, it can significantly improve the impact toughness to 26J through staged quenching

Such as 425°C sectional quenching, which is better than the traditional process.

High Temperature Strength and Ductility

Materials need to maintain high hardness and creep resistance at high temperatures.

Due to the optimised alloy composition, Dievar steel retains its high hardness (approx. 45 HRC) at 600°C, making it suitable for long-term high-temperature work.

Resistance to molten metal erosion

Aluminum and magnesium alloys are easy to react with the surface of the mold under high pressure.

H13 steel is formed by adding vanadium and molybdenum elements to form carbides, which effectively slows down the erosion rate.

Ease of processing and maintenance

The mold material needs to have good machinability to adapt to the precision machining of complex cavities.

For example, the ESR process improves the purity of H13 steel and reduces processing defects.

Future Development Trends

- New mold materials

- Intelligent mold design

New mold materials

Development of steel grades containing rare earth elements (e.g. H13 Ce) to further improve creep resistance and high-temperature strength.

Ceramic matrix composites, such as SiC-reinforced steels, exhibit better erosion resistance in the laboratory.

Intelligent mold design

Combined with AI simulation, the mold temperature field distribution is optimized, the thermal stress concentration is reduced, and the mold life is prolonged.