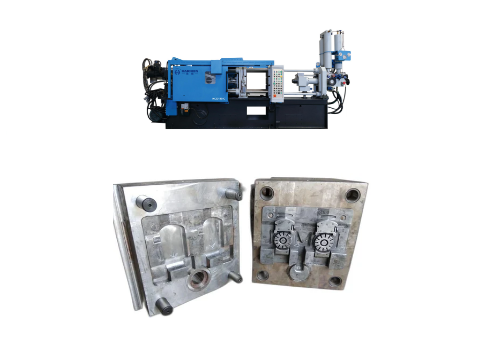

Die casting is an important process used in various industries. Die casting molds are an important part of the die casting process. The shape and characteristics of the Die casting mold will affect the characteristics of the final product.

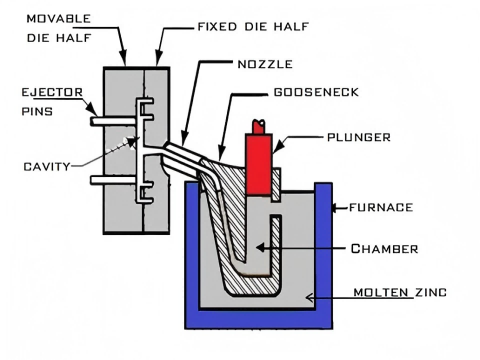

Die casting is a manufacturing process that involves casting metal under extreme pressure. The process requires heating the metal to a molten state and then reshaping the liquefied metal under high pressure. This process has been known to humans for a long time, dating back to the mid-19th century.

Die casting mold material offers several advantages that make it an ideal choice for industrial applications. Its lightweight and high strength offer superior performance compared to other materials. Furthermore, it is highly resistant to corrosion and heat, allowing it to be used to create complex shapes and components. Furthermore, die casting mold material is relatively inexpensive, allowing for large-scale production.

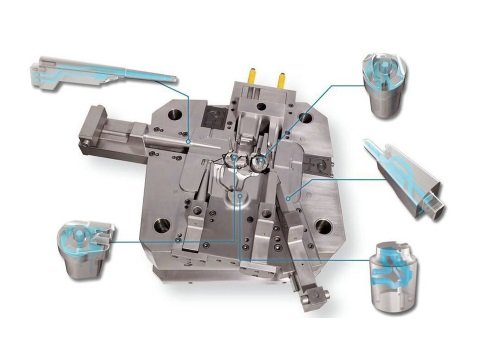

Main Structural Analysis of Die Casting Moulds

A die casting mold (or die) is a precision tool designed to shape molten metal into complex parts under high pressure. Its structure consists of several critical components that work together to ensure accurate, repeatable production. Here’s a detailed breakdown:

- Two Main Halves

- Core Components

- Additional Features for Complex Parts

- Materials and Durability

- Key Design Considerations

Two Main Halves

- Cover Die (Fixed Half):

- Attached to the stationary platen of the die casting machine.

- Contains the sprue (inlet for molten metal) and aligns with the machine’s injection system.

- Ejector Die (Moving Half):

- Attached to the moving platen and houses the ejector system.

- Separates from the cover die to release the solidified part after cooling.

Core Components

- Cavity and Core:

- Cavity: The recess in the cover die that forms the external shape of the part.

- Core: Protrusions (often in the ejector die) that create internal features (e.g., holes, undercuts).

- Cores can be fixed or movable (slides) for complex geometries.

- Gating System:

- Channels that guide molten metal into the cavity:

- Sprue: Entry point from the injection nozzle.

- Runners: Distribute metal to multiple cavities (in multi-cavity molds).

- Gates: Narrow openings that control metal flow into the cavity.

- Channels that guide molten metal into the cavity:

- Overflows and Vents:

- Overflows: Small pockets that trap impurities and excess metal.

- Vents: Thin channels that allow air/gas to escape, preventing porosity.

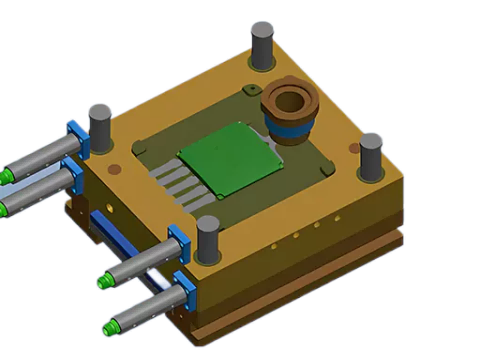

- Cooling System:

- Water/Oil Channels: Circulate coolant to regulate mold temperature, ensuring rapid solidification.

- Critical for reducing cycle time and preventing thermal stress.

- Ejector System:

- Ejector Pins: Push the solidified part out of the ejector die.

- Ejector Plate: Activates the pins via hydraulic or mechanical force.

- Alignment Features:

- Guide Pins and Bushings: Ensure precise alignment between the cover and ejector dies.

- Leader Pins: Maintain parallelism during clamping.

Additional Features for Complex Parts

- Slides and Lifters: Movable components that form undercuts or internal features.

- Inserts: Replaceable steel or ceramic pieces for high-wear areas (e.g., gate regions).

- Vacuum Systems: Remove air from the cavity to minimize porosity (common in aluminum/magnesium casting).

Materials and Durability

- Die casting Mold Steel:

- H13 (Hot-Work Steel): Most common for high-pressure dies (resists thermal fatigue).

- P20: Used for lower-volume production.

- Coatings:

- Nitriding or TiN (Titanium Nitride) to reduce wear and soldering.

Key Design Considerations

- Parting Line: The seam where the two die halves meet; critical for minimizing flash.

- Draft Angles: Slight tapers (1–3°) on vertical walls to ease part ejection.

- Wall Thickness: Uniform thickness (typically 1–5 mm) to prevent shrinkage defects.

Example: Automotive Bracket Die

- Cover Die: Contains the cavity for the bracket’s exterior.

- Ejector Die: Includes cores for mounting holes and an ejector pin system.

- Gating: A single sprue feeds into runners leading to four gates for balanced filling.

- Cooling Channels: Strategically placed near thick sections to prevent hot spots.

- Vacuum Valves: Extract air to ensure dense, defect-free castings.

Why the Structure Matters

- Precision: Tight tolerances (±0.1 mm) are achieved through precise alignment and cooling.

- Efficiency: Optimized gating and cooling reduce cycle times.

- Durability: High-grade steel and coatings extend mold life (100,000+ cycles).

For complex parts, CAD/CAM software (e.g., AutoCAD, SolidWorks) is used to simulate mold flow and optimize component placement.

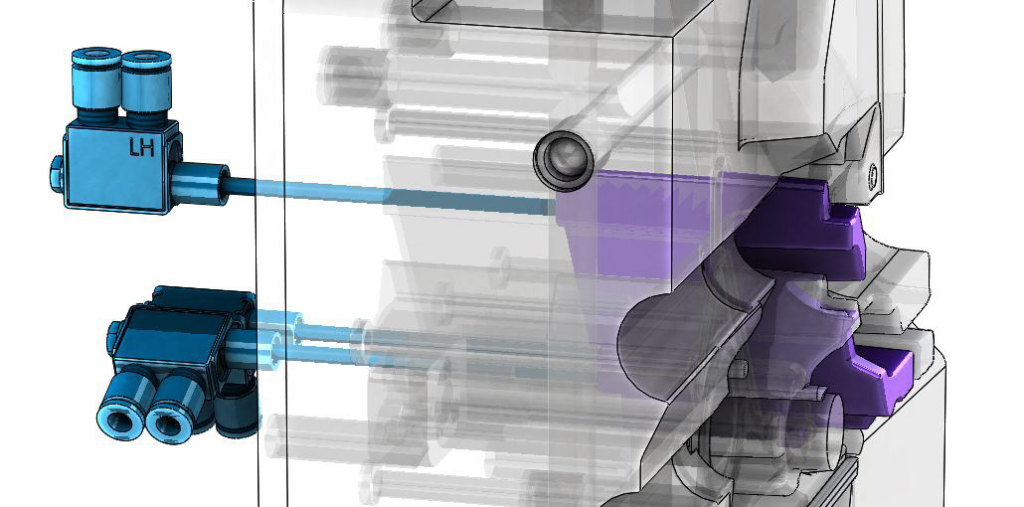

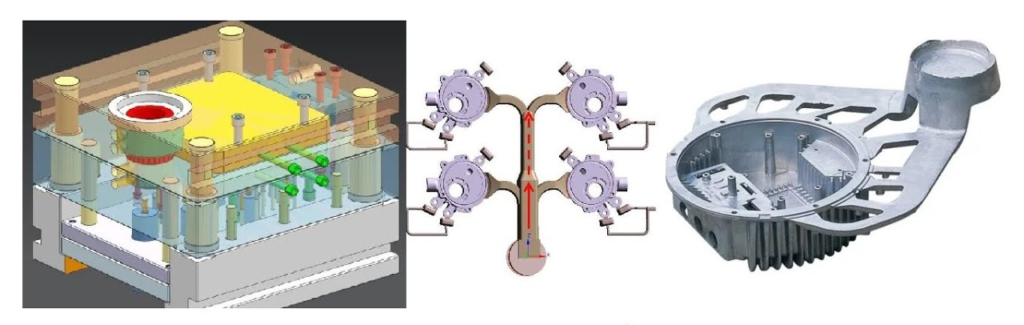

Special runner structure of die casting mold

The design of specialized runner systems in die casting molds is critical for achieving high-quality castings. Key features and technical considerations are outlined below:

- Basic Components of Runner Systems

- Specialized Runner Structures

- Key Design Principles & Optimization

- Application Cases & Innovations

Basic Components of Runner Systems

- Gate

- Serves as the entry point for molten metal into the cavity. Sharp corners must be avoided, and surfaces should be smooth to reduce flow resistance.

- Curved gate designs enhance flow stability, while undersized cross-sections may cause turbulence and gas entrapment.

- For zinc alloys, smooth runner surfaces are essential to maintain flow velocity.

- Runner

- Connects the gate to the cavity. Its cross-sectional area should gradually decrease from the sprue to the inner gate to prevent gas aspiration (negative pressure).

- Die casting runners are typically wider than those in plastic molds, with thickness not exceeding 75% of the casting’s wall thickness.

- Inner Gate

- Directly influences metal flow direction and pressure distribution. Positioned as the final channel before the cavity, its location must be optimized via simulations (e.g., CFD analysis) to avoid localized shrinkage.

Specialized Runner Structures

- Tilted Runner

- Replaces vertical runners with angled designs to improve filling uniformity. Multi-gate configurations (e.g., 4 localized gates) enhance metal distribution and reduce fill time, validated through flow simulations.

- Insulated Runner

- Uses a solidified plastic insulating layer to retain molten metal temperature and minimize heat loss. The runner volume must not exceed the cavity volume to ensure complete melt consumption per cycle.

- Hot Runner System

- Maintains constant temperature via heating elements to eliminate cold slugs. Direct integration of runners/gates into the casting saves material but increases costs, ideal for high-precision or expensive alloys.

Key Design Principles & Optimization

- Flow Control

- Balance melt velocity and pressure by optimizing runner dimensions, geometry, and placement. For example, magnesium alloys require runners adapted to their rapid heat dissipation.

- Venting & Overflow Systems

- Critical for gas evacuation. Overflow wells and vent slots must align with die casting machine parameters to ensure efficient gas removal.

- Material Compatibility

- Tailor runner designs to alloy properties (e.g., aluminum vs. magnesium fluidity). Validate designs through experiments and simulations (e.g., Flow-3D CAST).

Application Cases & Innovations

- Magnesium Alloy Optimization: A stepped runner design balanced flow velocity and temperature distribution, reducing porosity and improving solidification.

- Cold Chamber Die Casting: Runners must start within the upper two-thirds of the pressure chamber’s inner diameter to prevent premature metal solidification.

Specialized runner structures in die casting molds enhance filling efficiency and defect control through geometric optimization, material-specific adaptations, and advanced technologies (e.g., hot runners, simulation tools). These designs are pivotal for producing high-integrity castings in modern manufacturing.

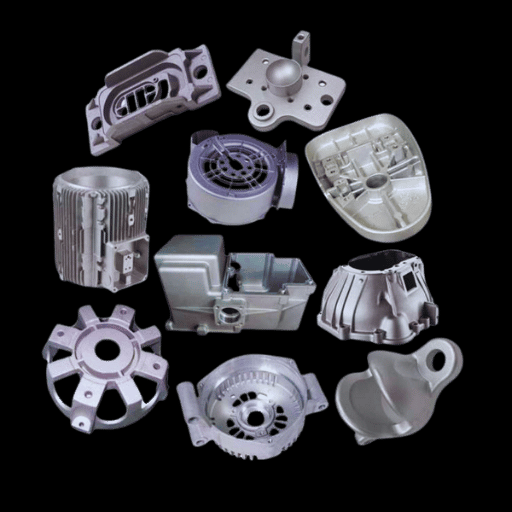

Haichen Design and manufacture of high-precision die-casting molds

Haichen’s Technical Advantages in High-Precision Die-Casting Mold Design and Manufacturing

- Advanced Design and Simulation Technology

- Multi-Stage Precision Control

- Material and Process Optimization

- Standardization and Quality Assurance

- Applications Across Industries

- Innovation and R&D

Advanced Design and Simulation Technology

Haichen employs CAD/CAE tools for mold optimization and Finite Element Analysis (FEA) to analyze dynamic/static characteristics of critical components (e.g., templates, locking structures). This ensures balanced stress distribution and structural stability. For instance, the C-series cold-chamber die-casting machines feature wider templates and extended locking distances to accommodate larger molds, while a five-point oblique locking mechanism enhances clamping precision. ProCAST casting simulation software is used to validate gating systems, temperature fields, and thermal balance, optimizing mold filling and reducing defects.

Multi-Stage Precision Control

Haichen’s die-casting machines integrate a four-stage injection control system, achieving ±0.1mm positional accuracy via magnetic scales and PLCs. Hydraulic systems use premium European/Japanese components (e.g., Siemens PLCs) and dual proportional valves to ensure stable injection speeds (up to 8m/s) and flexible pressure control (50.4–127.3 MPa). This enables production of complex geometries with high surface finishes, such as automotive parts and 3C components.

Material and Process Optimization

Haichen tailors molds and processes for different alloys (Al, Zn, Pb). For aluminum heat sinks and cookware, cold-chamber technology is paired with thermal balance optimization and high-temperature coatings to extend mold life. For large structural parts (e.g., EV components), additive manufacturing is used for rapid prototyping of complex cores, and multi-axis CNC machining handles deep cavities and intricate geometries.

Standardization and Quality Assurance

Haichen complies with Chinese (JB/T8083-2000) and EU (CE) standards, ISO 9001 certification, and GB/T 21269-2023 (Cold Chamber Die Casting Machines). High-rigidity frames and imported hydraulic components ensure assembly precision. Advanced metrology tools verify accuracy for oversized molds.

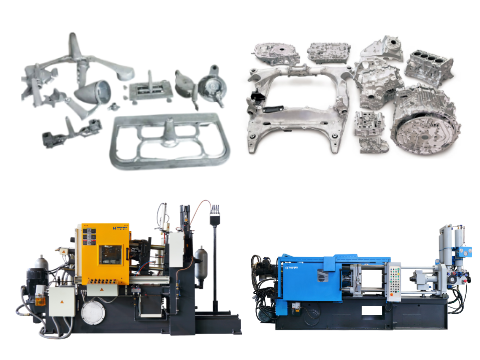

Applications Across Industries

- Automotive: Engine housings, motor rotors, and vacuum die-cast parts with enhanced airtightness.

- Consumer Electronics: Thin-walled aluminum housings (e.g., signal amplifiers) and heat sinks.

- Industrial/Consumer Goods: Zinc alloy medals, aluminum cookware, and automated production lines (e.g., robotic extractors, sprayers).

Innovation and R&D

Haichen invests in servo-driven systems, energy-efficient hydraulics, and smart interfaces (multi-language PLCs). R&D teams offer mold flow analysis and part design optimization to reduce costs and shorten lead times.

Core Competencies

Haichen’s strengths lie in its integrated design-manufacturing-validation workflow, global technical integration, and deep industry insights. From micro-components to EV chassis molds, Haichen delivers full solutions encompassing mold design, process optimization, and equipment support.

A die casting mold’s structure is engineered to balance precision, durability, and efficiency. From the cavity/core system to advanced cooling and ejection mechanisms, each component plays a vital role in producing high-quality parts.

This concise yet comprehensive overview highlights Haichen’s capabilities in precision die-casting for diverse industrial applications. Let me know if you need further details!