In die casting, understanding the Types of gooseneck in die casting is crucial for optimizing metal flow and improving casting quality.

In the world of die casting, the gooseneck plays a crucial role. It is the component that transfers molten metal from the injection system to the die cavity, ensuring a smooth and efficient casting process.

However, not all goosenecks are created equal. They come in various types, each designed to meet specific requirements of different die casting applications.

In this article, we will explore the common types of goosenecks used in die casting and their unique characteristics.

Straight Gooseneck

The straight gooseneck is the simplest and most traditional type. It features a direct, linear passage for the molten metal, which allows for a straightforward flow with minimal turbulence. This type is ideal for applications where the die cavity is easily accessible and aligned directly with the injection system. Its simplicity also means it is relatively easy to maintain and clean.

Key Characteristics:

- Flow Efficiency: Provides a smooth flow path for the molten metal.

- Low Maintenance: Easy to clean and inspect.

- Limitations: May not be suitable for complex die designs or applications requiring precise control over metal flow.

Curved Gooseneck

The curved gooseneck, as the name suggests, has a bent or curved shape. This design allows for better control over the direction and speed of the molten metal as it enters the die cavity. The curvature helps to reduce turbulence and ensures a more uniform filling of the cavity, which is essential for producing high-quality castings with minimal defects.

Key Characteristics:

- Flow Control: The curvature helps guide the metal flow more effectively.

- Reduced Turbulence: Minimizes air entrapment and improves casting quality.

- Versatility: Suitable for a wide range of die casting applications, including those with complex geometries.

Swan-neck Gooseneck

The swan-neck gooseneck is a more advanced type, often used in modern die casting machines. It features a distinctive S-shaped curve, which provides even greater control over the metal flow. This design is particularly effective in reducing splashing and air entrapment, leading to castings with superior surface finish and fewer internal defects.

Key Characteristics:

- Superior Flow Control: The S-shape ensures precise control over the metal flow.

- High-Quality Castings: Reduces the risk of defects such as porosity and inclusions.

- Complex Applications: Ideal for intricate die designs and high-precision casting requirements.

Adjustable Gooseneck

The adjustable gooseneck offers flexibility in terms of its orientation and position. You can adjust this type of gooseneck to different angles and lengths, which makes it highly adaptable to various die casting setups. It’s particularly useful in situations where the die cavity’s position may vary or when multiple die designs are used on the same machine.

Key Characteristics:

- Versatility: Can be adjusted to fit different die designs and machine configurations.

- Customization: Allows for fine-tuning of the metal flow based on specific application needs.

- Efficiency: Reduces the need for multiple goosenecks, saving on maintenance and replacement costs.

Applicability of Gooseneck in Die Casting Machines

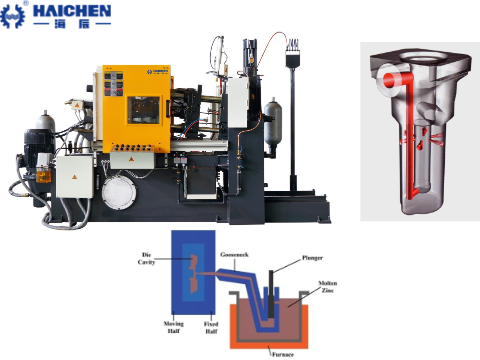

The gooseneck is primarily used in hot – chamber die – casting machines, which are also known as “gooseneck machines.” These machines are suitable for low – melting – point alloys such as zinc and magnesium。The gooseneck mechanism allows for fast cycle times and efficient production, making it ideal for high – volume manufacturing.

HAICHEN Die Casting Machines

HAICHEN offers a range of high – precision die – casting machines, including hot – chamber and cold – chamber types. Our hot – chamber die – casting machines are equipped with advanced gooseneck systems that ensure efficient metal transfer and high – quality castings。These machines are designed to handle various metals and alloys, providing flexibility and reliability for different production needs.

HAICHEN: Leading Die Casting Machine Manufacturer

At HAICHEN, we understand the importance of selecting the right gooseneck for your die casting operations. Our advanced die casting machines are designed to accommodate various types of goosenecks, ensuring optimal performance and flexibility. Whether you need a simple straight gooseneck for basic applications or a sophisticated swan-neck gooseneck for high-precision casting, HAICHEN has the solution to meet your needs.

Our commitment to innovation and quality ensures that our machines are equipped with the latest technology to enhance productivity, reduce downtime, and improve overall casting quality. By choosing HAICHEN, you are choosing a partner dedicated to helping you achieve excellence in your die casting processes.

The type of gooseneck you choose for your die casting operations can significantly impact the quality and efficiency of your castings. Understanding the different types and their characteristics is essential for making the right decision.