Choose gooseneck in die casting includes material characteristics, heat resistance and mechanical strength, structural design and so on.

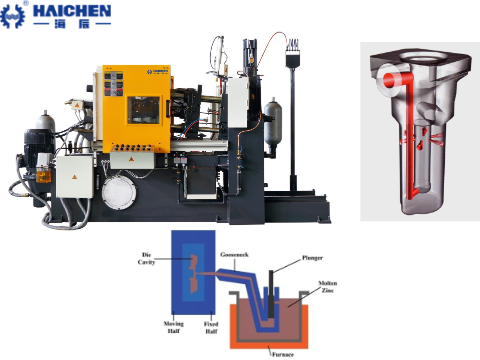

In a hot chamber (gooseneck) die-casting machine, the gooseneck is the critical channel that transports molten metal from the furnace to the die. When selecting a die casting machine, consider the machine’s technical specifications, the volume and quality requirements of the part being processed, and the characteristics of the alloy being used.

When choosing a gooseneck, you need to consider the characteristics of the processed metal. Such as the heat resistance and mechanical strength of the gooseneck, the design structure, maintenance costs, and temperature control. By choosing the right gooseneck, you can ensure the efficiency of the die casting process and the quality of the product.

We will analyze how to choose die casting gooseneck mainly from below six aspects:

- Material characteristics

- Structural design

- Heat resistance and mechanical strength

- Maintenance and Replacement

- Temperature control

- Applicability

Material characteristics of choose gooseneck in die casting

Gooseneck mainly uses for hot chamber die casting. And it is suitable for low melting point metals such as zinc, magnesium and some aluminum alloys.

- High-quality cast/forged steel

- Everdur Bronze (UNS87300)

- Gray cast iron, ductile iron

- Surface coatings (Si-DLC, nitriding, carburizing)

If high melting point metals (such as aluminum, copper, magnesium, etc.) are used, gooseneck is not suitable because these materials will damage the gooseneck and other related parts.

Therefore, when selecting a gooseneck, it is necessary to ensure that its material can withstand the high temperature and process the chemical properties of the metal.

High-quality cast/forged steel

- Used for the gooseneck body of most hot chamber die casting machines.

- Offers high thermal resistance, strength, and wear resistance.

Everdur Bronze (UNS87300)

- It is suitable for gooseneck parts in marine or corrosive environments.

- Chosen for its excellent corrosion resistance and castability.

Gray cast iron, ductile iron

- This is a suitable alternative in cost-sensitive applications.

- But with slightly lower temperature and corrosion resistance.

Surface coatings (Si-DLC, nitriding, carburizing)

- Improve wear resistance and oxidation resistance

- especially in the high-temperature and high-pressure environments of hot chamber die casting.

Heat resistance and mechanical strength

The gooseneck needs to have high heat resistance to withstand the high temperature of molten metal.

Usually, the gooseneck is made of gray cast iron, alloy steel or cast steel. In addition, the cylindrical inner cavity of the gooseneck needs to be able to withstand the pressure of the hydraulic injection system. So its mechanical strength is also very important.

- Heat Resistance

- Mechanical Strength

- Lifespan and Reliability

Heat Resistance

- Goosenecks typically withstand operating temperatures of approximately 380°C–450°C in zinc alloy die-casting; this can rise to 650°C for high-melting-point materials such as magnesium alloys.

- Hot-work tool steels (H13, SKD61, 8407) or high-quality forged steels can meet these temperature requirements and provide sufficient thermal conductivity to reduce thermal gradients.

Mechanical Strength

- Experimental data shows that hot-chamber goosenecks have an ultimate tensile strength of approximately 337 MPa.

- And a yield strength of approximately 220 MPa, sufficient to withstand the mechanical loads generated by high-pressure injection (>300 bar).

- Hot-work steels have a higher yield strength (>1500 MPa) and maintain excellent ductility at high temperatures, preventing thermal cracking.

Lifespan and Reliability

Through material heat treatment (carburizing and low-temperature tempering) and structural optimization. They can achieve thousands of flawless firing cycles, significantly improving resistance to thermal cracking and thermal fatigue.

HAICHEN choose gooseneck case study

We always help our clients select the right gooseneck to overcome specific challenges.

- Eliminate Nozzle Blockage

- HAICHEN Advantage of integrated system solutions

Eliminate Nozzle Blockage

One of Haichen clients who producing zinc door fittings, faced frequent nozzle blockages. This caused unstable production and high scrap rates. Their old gooseneck had poor temperature control and a rough inner surface. HAICHEN engineers recommended a precision-machined gooseneck with superior heating uniformity. After installation, blockages were eliminated, scrap rates dropped by over 20%, and production stability significantly improved.

HAICHEN Advantage of integrated system solutions

Haichen, as a die casting machine manufacturer, we don’t just supply parts. We provide complete solutions. Our goosenecks are engineered to work perfectly with our hot chamber machines. This ensures optimal performance, longevity, and seamless after-sales support. Choosing HAICHEN means investing in a reliable, high-performance system.

Structural design of choose gooseneck in die casting

The design of the gooseneck should ensure that the molten metal can flow smoothly into the mold cavity.

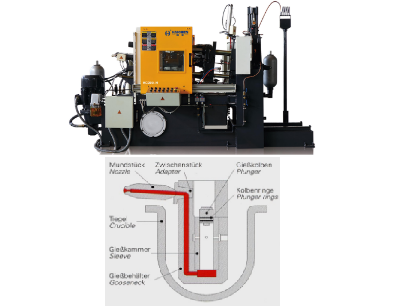

Its shape is similar to a gooseneck, hence the name. One end of the gooseneck is immersed in the molten metal pool. And the other end connects to the mold cavity through a nozzle.

When designing, it is necessary to ensure that the channel of the gooseneck is wide enough to accommodate the molten metal. And that the connection between the nozzle and the mold cavity well seales to prevent metal leakage.

- Functional Positioning

- Material and Surface Treatment

- Thermal Design

- Geometry and Dimensions

Functional Positioning

- As the core channel of a hot chamber die casting machine, the gooseneck connects the injection mechanism to the molten metal pool.

- Transport the metal from the pool to the nozzle and into the die cavity.

- It typically contains a cylindrical sleeve that houses the injection components, such as the hot chamber and piston.

Material and Surface Treatment

- It must possess high heat resistance, corrosion resistance, and strength, and high-quality cast or forged steel is commonly used.

- To improve wear resistance and chemical corrosion resistance, niobium (Nb) lining or Si-DLC (silicon-doped diamond-like carbon) coating is often used internally. The latter performs best in immersion tests.

- For aluminum hot die casting, specialized materials such as aluminum-corrosion-resistant niobium gooseneck or Anviloy nozzles are required.

Thermal Design

- The gooseneck is immersed in the molten metal for extended periods and must maintain high thermal resistance to prevent heat transfer to the injection mechanism and deformation.

- The standard operating temperature range (using zinc alloy as an example) is 430°C ± 20°C, while magnesium alloys are approximately 650°C, and aluminum alloys are even higher, requiring corresponding material upgrades.

- The design must ensure uniform temperature to avoid local overheating and radial deformation.

Geometry and Dimensions

- A combination of curved and cylindrical bushings is used to achieve smooth flow and reduce pressure drop.

- Critical dimensions (such as inlet diameter and bend radius) are determined through fluid-structure interaction (FSI) analysis to balance flow rate, pressure, and thermal expansion.

Maintenance and Replacement

The gooseneck may gradually wear out due to high temperature and chemical corrosion during long-term use. Therefore, the gooseneck is usually a replaceable part. When selecting a gooseneck, it should consider the durability and maintenance cost. Then to ensure production efficiency and cost-effectiveness.

Temperature control

To prevent the molten metal from cooling in the gooseneck, the nozzle usually needs to be heated to 400-500°C, which can be achieved by gas, electric or induction heating. Therefore, when selecting a gooseneck, make sure it is compatible with the heating system and that the heating process can evenly distribute the heat.

Applicability

The hot chamber die casting machine (also called gooseneck die casting machine) is one of the most commonly using die casting equipments on the market. It is suitable for occasions where fast mold filling is required. If production needs have high requirements for filling speed and accuracy, the hot chamber die casting machine and its gooseneck may be the best choice.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.