Plunger Tip for Die Casting includes its function, material selection, customization and maintenance, design and optimization and so on.

The plunger tip is a critical component of the die-casting machine’s shot-jetting system. Its design must balance cooling efficiency, material strength, lubrication and sealing, and geometric matching.

Selecting high-thermal-conductivity materials, optimizing water flow design, and employing appropriate lubricants. The plunger tip’s life can be significantly improved, cycle times can be reduced, and casting quality can be guaranteed.

The plunger tip used in the die casting process is an important component of the die casting machine. Its design and material selection have an important impact on the efficiency of the die casting process and the product quality.

- Function of the plunger tip die casting

- Material selection of die casting plunger tip

- Customization and maintenance of plunger tips

- Design and optimization of plunger head

- HAICHEN’s Expertise with Plunger Tip Solutions

- Application scenarios of plunger heads

Function of the plunger tip die casting

The main function of the plunger head is to inject molten metal into the mold cavity under high pressure.

- Primary function

- Operation

In hot chamber die casting machine, the plunger head usually locates in an injection system immersed in molten metal. Driven by hydraulic or mechanical means to inject molten metal into the mold cavity through the gooseneck and nozzle.

The plunger head needs to withstand high temperature and high pressure environment, so its material must be resistant to high temperature, wear and impact.

Primary function

Transmitting the immense pressure generated by the machine (typically exceeding 1000 bar) to the molten metal.

Operation

Within an extremely brief period (milliseconds), rapidly injecting molten metal from the top of the shot sleeve into the mould cavity to ensure complete filling and prevent porosity and unfilled defects.

Material selection of die casting plunger tip

The plunger head is usually made of high temperature resistant materials, such as copper alloy or other heat resistant metals. These materials can withstand high temperature and high pressure environments, while having good wear resistance and impact resistance.

In addition, the surface treatment of the plunger head is also important, such as plating or coating can further improve its corrosion resistance and service life.

Choosing the right material is crucial for plunger tip performance and longevity. The material must withstand high temperatures, resist wear, and maintain stability under cyclic stress.

For Aluminum Alloys

Materials must resist high temperature (around 660°C), aluminum soldering, and abrasive wear from silicon content. Premium hot-work tool steels like H13 with proper heat treatment are standard.

Zinc Alloys

The focus is on corrosion resistance against molten zinc and maintaining strength at lower temperatures (around 420°C). Special surface treatments or bronze alloys are often used.

Magnesium Alloys

Requires high resistance to thermal fatigue and oxidation. Nickel-based alloys or specially coated steels are common choices.

Common Material Grades and Their Properties

- Tool Steels (e.g., H11, H13): Offer a good balance of toughness, thermal fatigue resistance, and cost. They are widely used for aluminum casting.

- Nickel-Based Alloys: Provide superior high-temperature strength and corrosion resistance, ideal for demanding applications or magnesium.

- Copper-Beryllium Alloys: Excellent thermal conductivity reduces heat checking, but cost and safety in handling are considerations.

The Role of Coatings and Surface Treatments

- Nitriding: Increases surface hardness and wear resistance, extending tip life significantly.

- Ceramic Coatings: Provide extreme resistance to soldering and oxidation, suitable for high-silicon aluminum.

- Physical Vapor Deposition (PVD): A thin, hard coating like TiN or CrN reduces friction and adhesion.

Customization and maintenance of plunger tips

Some die-casting machine users customize plunger heads according to specific needs to adapt to specific mold design or production requirements. In addition, plunger heads may wear due to high temperature and high pressure during use, so they need to be inspected and replaced regularly. In order to extend the service life of the plunger head, special lubricants can also be used to reduce wear.

Customization for Specific Applications

- Size and Shape: Tips can be customized in diameter, length, and face geometry (flat, concave) to match non-standard shot sleeves or special flow requirements.

- Material Specification: For unique alloys or extreme conditions, material composition can be tailored.

- Integration with Accessories: Custom designs can incorporate cooling channels or sensor mounts for advanced process control.

Matching the Tip to the Mold and Process

- Shot Sleeve Diameter: The tip diameter must match the sleeve with the correct clearance (typically 0.10-0.20mm per side) to ensure sealing without excessive friction.

- Injection Profile: The tip design can influence metal turbulence. Optimization is sometimes needed for very fast or slow shot profiles.

- Lubrication Compatibility: The tip material and coating must work effectively with the specific die lubricant used.

Maintenance Schedule and Best Practices

- Regular Inspection: Check for cracks, scoring, pitting, or signs of soldering after every production run or during scheduled downtime.

- Proper Installation: Ensure the tip is clean, correctly torqued onto the rod, and properly aligned to prevent uneven wear.

- Cleaning and Storage: Remove any metal build-up carefully. Store tips in a dry place to prevent rust.

Design and optimization of plunger head

The design of plunger head needs to consider its size, shape and material properties. For example, the diameter and length of plunger head will affect its injection molding capacity and application range.

When designing, it is also necessary to consider the sealing between plunger head and mold cavity to ensure that molten metal can evenly fill the mold cavity.

Geometric Design and Its Impact on Performance

- Face Geometry: A flat face is common. A slightly concave face can help centralize pressure and reduce leakage in some applications.

- Cooling Features: Some high-end tips incorporate internal cooling near the face to manage temperature and reduce thermal stress.

- Transition Radii: Smooth radii between the face and body reduce stress concentration and crack initiation points.

Thermal Management and Heat Checking Prevention

- Material Thermal Conductivity: Choosing a material with good conductivity helps dissipate heat from the tip face, reducing the thermal gradient.

- Design for Heat Dissipation: A larger mass or specific design features can act as a heat sink.

- Process Control: Optimizing cycle time and lubrication helps control the tip’s operating temperature, preventing heat checking (network of small cracks).

Optimization for Wear Resistance and Leak Prevention

- Clearance Optimization: The ideal radial clearance creates a dynamic seal: molten metal solidifies in the gap just ahead of the tip, preventing leakage without causing galling.

- Surface Finish: An extremely smooth finish on the tip’s outer diameter minimizes friction and wear against the shot sleeve.

- Edge Design: A sharp, clean leading edge helps shear through any solidified skin in the sleeve, maintaining a consistent seal.

HAICHEN’s Expertise with Plunger Tip Solutions

We help clients optimize the die casting pluger tip-this consumable part for better performance and cost.

- Solve Premature Wear for an Aluminum Parts producer

- HAICHEN Advantage of precision and support of die casting machine spare parts

Solve Premature Wear for an Aluminum Parts producer

A auto parts manufacturer with a HAICHEN 880-ton cold chamber die casting machine. Their plunger tips for aluminum alloy wore out every 10,000 shots, causing frequent stops. HAICHEN engineers found the original tips could not handle their specific alloy’s high silicon content. We recommended and supplied a batch of tips made from a proprietary, abrasion-resistant grade of steel. The new tips lasted over 35,000 shots under the same conditions. This change reduced their spare part cost by 65% and increased machine availability.

HAICHEN Advantage of precision and support of die casting machine spare parts

This case highlights our strength. HAICHEN designs plunger tips for perfect fit and durability in our machines. We offer material options for different casting challenges. More than just selling parts, we provide analysis and recommendations to solve root causes. For our clients, this means longer component life, stable production, and lower total operating costs.

Application scenarios of plunger heads

Plunger heads widely use in various die casting processes, including hot chamber die casting and cold chamber die casting. In hot chamber die casting, the plunger head directly immerse in the molten metal, which is suitable for low melting point metals. Such as zinc, magnesium and lead; while in cold chamber die casting, the plunger head manually or mechanically injects the molten metal into the mold cavity.

The plunger head is an indispensable key component in the die casting process. Its performance directly affects the quality and production efficiency of die castings. Selecting the right material, optimizing the design and regular maintenance are important measures to ensure the normal operation of the plunger head.

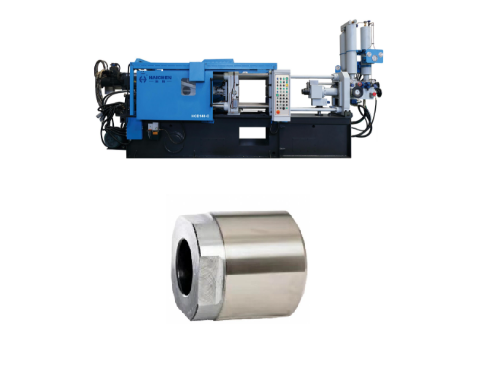

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.