When selecting die casting plunger tips, key factors include material compatibility with the molten metal, tip geometry for optimal flow and pressure control, durability to withstand high – pressure injection, and ease of maintenance and replacement to ensure consistent performance and minimize downtime.

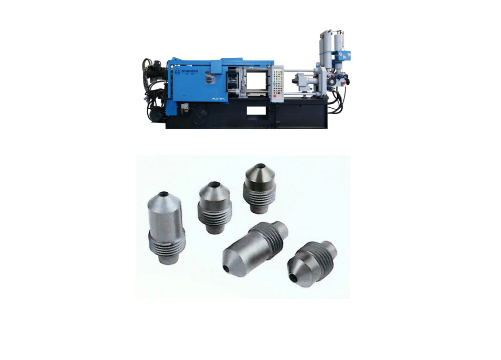

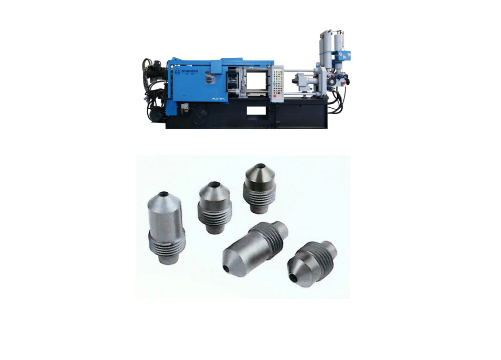

Die casting is a precision manufacturing process that requires careful attention to detail at every stage. One often overlooked yet crucial component is the die casting plunger tip.

The plunger tip plays a vital role in the injection process, ensuring that molten metal is delivered smoothly and efficiently into the mold cavity.

Selecting the right plunger tip can significantly impact the quality, efficiency, and longevity of your die casting operations.

In this article, we will explore the key factors to consider when choosing die casting plunger tips.

Material Composition

The material used for the plunger tip is a primary consideration. High-temperature resistance and durability are essential, as the tip will be in direct contact with molten metal.

Common materials include high-grade steel and specialized alloys designed to withstand the extreme conditions of die casting.

At HAICHEN, we use advanced materials and manufacturing processes to ensure our plunger tips are both robust and reliable.

Tip Geometry

The geometry of the plunger tip affects how molten metal flows into the mold. A well-designed tip will minimize turbulence and air entrapment, resulting in a smoother injection and higher-quality castings.

The shape and size of the tip should be matched to the specific requirements of the die casting machine and the mold design.

HAICHEN offers a variety of plunger tip geometries to suit different applications, ensuring optimal performance in every scenario.

Surface Finish

A smooth surface finish on the plunger tip is critical for reducing friction and preventing metal adhesion.

This not only improves the efficiency of the injection process but also extends the life of the tip.

HAICHEN’s plunger tips undergo precision machining and surface treatment to achieve a high-quality finish that enhances performance and durability.

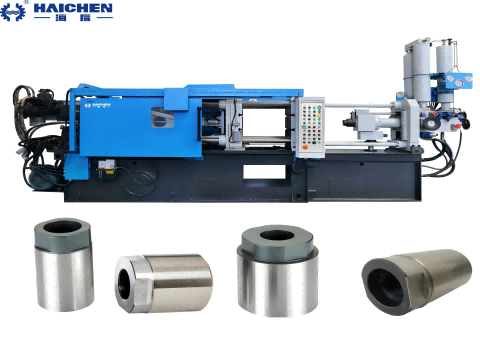

Cooling System

Effective cooling is essential for maintaining the temperature stability of the plunger tip.

A well-designed cooling system helps to prevent thermal expansion and reduces the risk of tip deformation.

HAICHEN’s plunger tips are equip with advanced cooling channels that ensure consistent temperature control. Resulting in more stable and efficient die casting operations.

Customization Options

Every die casting operation is unique, and the plunger tip should be tailored to meet specific requirements.

HAICHEN offers a range of customization options, allowing customers to specify the material, geometry, and other features of the plunger tip to match their exact needs.

This flexibility ensures that the plunger tip will perform optimally in any application.

HAICHEN’s Innovative Practices in Die Casting Punches

As a professional die casting machine manufacturer, HAICHEN has developed a series of innovative punch solutions to address practical problems in die casting production, which have been validated in practice.

- Multi-Layer Composite Coating Technology

- Intelligent Punch Management System

Multi-Layer Composite Coating Technology

To solve the problems of punch surface wear and molten aluminum adhesion, HAICHEN employs multi-layer composite coating technology. Through advanced surface treatment processes such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), a robust protective layer is formed on the punch surface.

Practical application data shows that this treatment increases punch lifespan by 40%-60%, while reducing casting defects caused by punch wear, improving product consistency and production efficiency.

Intelligent Punch Management System

HAICHEN also integrates IoT technology into punch management, developing a punch usage status monitoring system. This system predicts the remaining lifespan of the punch by monitoring real-time changes in punch temperature, number of cycles, and pressure, and indicates maintenance time.

This system effectively avoids unplanned downtime caused by sudden punch failure, reducing the punch-related failure rate by more than 30% and improving the overall efficiency and stability of the production line.

Die-casting parts: what the plunger tip leaves behind

Because the tip directly influences flow turbulence, filling time and entrained oxide films, its material and surface finish become part of the casting quality signature.

The plunger tip is a “hidden variable” that ends up written into every micro-structure, pore and surface finish of the part you ship.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we understand the importance of every component in the die casting process.

We design and manufacture our plunger tips to the highest standards, ensuring they deliver consistent performance and reliability.

Whether you are starting a new die casting project or looking to upgrade your existing equipment, HAICHEN has the expertise and solutions to meet your needs.

Case: Solving Early Plunger Tip Failure in Large Aluminum Structural Part Production

A customer using a 1000-ton machine to produce new energy vehicle battery tray frames (aluminum) experienced severe head wear and heat cracking on their original plunger tips after only about 8,000 shots. This led to increased casting flash and decreased internal density. HAICHEN analysis identified that the part’s large projected area, high injection pressure, and short cycle time placed extreme demands on the tip’s thermal shock and high-temperature wear resistance.

Selecting the right die casting plunger tip is essential for achieving high-quality castings and efficient production.

By considering factors such as material composition, tip geometry, surface finish, cooling system, and customization options, you can make an informed decision that will benefit your die casting operations.