Manufacturer of Plunger Tips for Die Casting Machines:

- L.K. Group

- Bühler

- FRECH

- UBE Machinery

- Yizumi Group

- Italpresse

- Zitai Precision Machinery

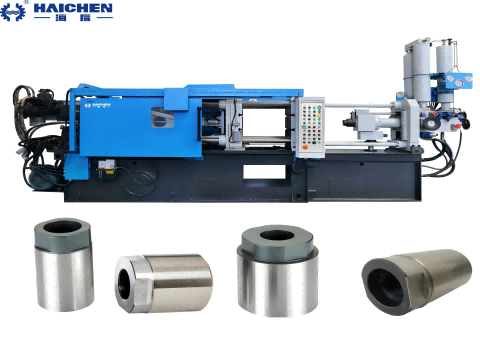

- Haichen

Plunger tips also known as the plunger head of the die casting machine is the core component of the die casting process.

And plunger tips design, materials and maintenance directly affect the casting accuracy, production efficiency and equipment life.

The plunger head is a critical component in the aluminum die casting process. Its successful operation depends on a variety of factors.

The most important factor is its effective fit with a round, straight, thermally stable and therefore dimensionally stable pressing sleeve.

Haichen‘s plunger heads are particularly suitable for die casting processes.

All copper alloys are refined from pure copper, heated and cast in a high vacuum environment to avoid oxidation, and then forged and heat precipitated.

The alloy combines high fatigue strength, high hardness, high heat resistance, and high thermal conductivity.

The function of the plunger tips

The plunger tip ensures uniformity and stability of the filling process by precisely regulating the flow of molten metal into the mold cavity, thereby reducing defects such as porosity and shrinkage porosity.

In high-pressure die casting (HPDC), the injection speed and pressure are controlled in stages by hydraulically or mechanically actuating the plunger motion to avoid air entrapment and compensate for metal shrinkage.

In addition, the fit tolerance of the plunger tips to the injection sleeve directly affects the tightness and consistency of the metal flow.

Die casting plunger heads and lubricants are essential for optimizing the die casting process.

By selecting the right materials, maintaining them properly, and making the most of advanced technologies, manufacturers can achieve exceptional results.

Investing in the right tools and processes not only enhances efficiency but also ensures long-term success in the die casting industry.

Explore Haichen’s comprehensive range of high-quality plunger heads and lubricants to enhance the efficiency of your die casting operations. Contact us today for expert guidance and tailored solutions.

Durability in high-temperature and high-pressure environments

The plunger tip needs to withstand high temperatures (typically 600-800°C) and injection pressures (up to more than 100 MPa) of molten metal (e.g., aluminum alloys, magnesium alloys).

So the material needs to be resistant to high strength, abrasion and thermal shock.

Material innovation trends

Copper alloys: Uniform microstructure and high thermal conductivity (>200 W/m·K) reduce thermal stress deformation and extend service life.

Surface coating technologies, such as nickel-based coatings or laser cladding, improve the wear resistance of ductile iron or steel substrates.

Design features of the plunger tip

- Segmented design

- Sealing device

Segmented design

Divided into a connecting section (connected with the thrust mechanism) and a pusher section (pushing the metal).

The diameter of the pusher section is larger to enhance the thrust and reduce the stress concentration through the arc transition.

Sealing device

O-ring or lip seal to prevent metal leakage and maintain injection pressure.

Plunger Tips Compatibility & Customization

Shape and size can be customized according to the machine model and casting needs, such as:

Automotive: short-stroke, large-diameter plunger head for faster filling.

Precision electronics: Slim plunger head to control flow accuracy.

L.K. Group

- Market position

- Technical features

- Customer testimonial

Market position

The world’s largest die-casting machine manufacturer in terms of sales, with a market share of more than 90% in the ultra-large die-casting machine market in 2022, with customers including Tesla, GM, BYD, etc.

Technical features

The plunger head is made of copper alloy material (such as the high thermal conductivity copper base material of Powerway alloy) to improve the heat dissipation efficiency and life.

The clamping force covers 60,000-160,000 kN, which is suitable for the needs of integrated die casting.

The direct-pressure clamping structure reduces thermal deformation and ensures cycle stability.

Customer testimonial

Tesla’s Model Y body-chassis integrated die-casting process is the core equipment supplier, reflecting the reliability of its plunger head in ultra-large die-casting.

Bühler

- Market position

- Technical features

- Customer evaluation

Market position

The world’s leading high-end die-casting machine, with a market share of more than 50% in the field of structural parts, and customers covering the automotive and 3C industries.

Technical features

Standardized application of copper alloy plunger head, with two platen direct pressure clamping mechanism (such as Carat 920 series).

Optimized thermal conductivity design supports the efficient operation of the 9200T ultra-large die casting machine.

Customer evaluation

Excellent performance in the production of precision components such as battery housings for electric vehicles, with a 23.4% increase in die casting revenue in 2023.

FRECH

- Technical expertise

- Applications

Technical expertise

The cold chamber die casting machine is technologically advanced, and the plunger head design emphasizes low friction and resistance to thermal fatigue.

Applications

Scenarios that require high precision, such as automotive engine parts, have a prominent market share in Europe.

UBE Machinery

- Regional advantages

- Innovation

Regional advantages

The market leader in Japan and Asia, the plunger head material is mainly made of high-hardness steel, suitable for small and medium-sized die-casting machines.

Innovation

Research and development of all-electric die-casting machine, plunger head motion control accuracy of ±0.05mm.

Yizumi Group

The LEAP series die-casting machine adopts servo direct control technology, and the closed-loop control accuracy of the plunger head is ±0.1MPa.

The injection speed of the D-Speed 350 model is ≥12m/s, which is suitable for the production of ultra-thin-walled 3C parts.

Market performance

The market share of domestic cold chamber die-casting machines is 14%, gradually replacing imported equipment.

Italpresse

- Technical Highlights

- Customer Case

Technical Highlights

TF series knuckleless die-casting machine adopts forging template, and the life of the plunger head is increased by 30%.

Vacuum casting technology reduces porosity and adapts to safety components such as automobile suspensions.

Customer Case

China Huicheng Foundry purchased the TF4400 model, recognizing its structural rigidity and low maintenance cost.

Zitai Precision Machinery

- Product positioning

- Market coverage

Product positioning

Focus on cold chamber die-casting machine, plunger head material is made of self-developed high wear-resistant copper alloy.

Market coverage

Clamping force 100-2500T, suitable for small and medium-sized parts, cost-effective advantages.

Haichen Plunger

The efficient operation of the plunger tip of a die-casting machine relies on the comprehensive optimization of material science, structural design and strict maintenance.

With the application of high conductivity copper alloy and intelligent lubrication system, the life of the plunger tip and the die casting efficiency will be further improved.

Haichen selects the adaptation scheme according to the production needs, and reduces the failure rate through standardized maintenance processes to reduce costs and increase efficiency.