Nozzle manufacturers in die casting in China are mainly concentrated in the Pearl River Delta and Yangtze River Delta regions.

Actually,die casting nozzles are essential die casting parts for die casting machines used to spray release agents or coolants, ensuring the efficiency and quality of the die casting process.

According to the evidence, China’s die casting industry is developed as a whole, with many die casting equipment and accessories manufacturers.

Haichen is a die casting machine and related accessories manufacturer that you can trust.

Definition and main uses of die casting nozzles

The die-casting nozzle is a key component in die-casting technology, and its primary function is to direct the molten metal.

Through the gooseneck into the mold’s gate system and ensure that the metal enters the mold passage in a smooth, directional manner.

Actually,the design of the nozzle usually includes a flow channel that forms a cavity with the mold component in the die casting mold.

Which is mostly made of powder metallurgy wear resistant materials to improve wear resistance.

The main uses of die casting nozzles

- Guide the molten metal

- Cooling and mold release

- Improved product quality

- Adapt to different application scenarios

Guide the molten metal

The nozzle regulates the flow direction of the molten metal, ensuring that the metal can enter the mold’s gate system smoothly.

Cooling and mold release

In some cases, nozzles are also used to cool the mold surface or spray release agents to prevent casting sticking and improve production efficiency.

Improved product quality

By optimizing nozzle design and process parameters, defects can be reduced and the surface quality and production efficiency of castings can be improved.

Adapt to different application scenarios

In some cases,engineers can adjust the nozzle’s design and material to meet the needs of different die-casting processes.

For example, magnesium alloy and aluminum alloy nozzles suit different types of die-casting machines.

Die casting nozzles play a vital role in the die casting process.

Not only affecting the fluidity of the metal and the quality of the casting.

But also directly related to production efficiency and cost control.

Nozzle manufacturers in die casting in China

- Dongguan Meixin Automation Technology Co., Ltd

- Dongguan Suyuan Spray Technology Co., Ltd

- Shanghai Lezhou Machinery Parts Co., Ltd.

- Suzhou Yadlin Co., Ltd

- Wallin Spraying Technology (Suzhou) Co., Ltd.

- Ningbo Haichen Machinery

Dongguan Meixin Automation Technology Co., Ltd

The company focuses on the research and development, production.

And sales of die-casting machine accessories, nozzles, spray guns, spray systems.

In some cases,and other products, and has a complete and scientific quality management system.

Its products include thermocouples, PT00 RTDs, temperature sensors, bimetal thermostats.

Besides,die-casting machine accessories, manipulator automatic spray heads, release agents and others.

Technical advantages

Through years of technology accumulation and research and development.

The company has formed an automated design and layout technology.

To realize the linkage between production machinery, improve the automation of the production process, reduce manual use, save costs and improve production efficiency.

In addition, the company also provides customized services to design.

And develop special nozzles for various applications according to customer needs.

Dongguan Suyuan Spray Technology Co., Ltd

The company specializes in the production of various types of nozzles, spray systems, filters and other purification equipment accessories.

Modern nozzle manufacturing equipment can process all kinds of plastic, metal, ceramic and other material nozzles according to customer requirements.

Technical advantages

The company has a group of experienced design and development team, with a number of international level precision measurement.

Drive control, advanced manufacturing in the field of core technology and advanced modern nozzle manufacturing equipment.

The nozzle product is guaranteed with an accuracy of 2°C and 2% of the spray volume tolerance in clean water at room temperature and standard pressure.

Shanghai Lezhou Machinery Parts Co., Ltd.

Covering stainless steel, die casting parts, metal and other material nozzles.

Suitable for industrial cleaning, spraying and other fields, with an annual turnover of 20.01 million to 30 million.

Suzhou Yadlin Co., Ltd

Develop profiling nozzles and micro-precision spraying technology to serve the die-casting of auto parts, improve mold life and product consistency.

Wallin Spraying Technology (Suzhou) Co., Ltd.

DDV and DELTASPEED nozzles enable quantitative and accurate spraying of release agents, cutting consumption by over 20%.

Ningbo Haichen Machinery

Ningbo Haichen machinery was founded in 2005, Located in Ningbo, Zhejiang, China.

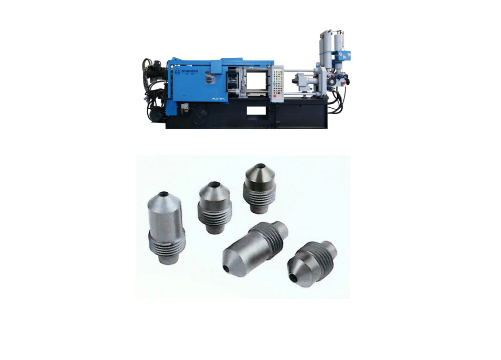

HAICHENspecializes in the production and sale of hot chamber die-casting machines, cold chamberdie-casting machines, servo die casting machines, die casting parts and relative auxiliary equipment.

HAlCHEN always places more emphasis on the technology and management. Because of its ad-vanced technology, high quality and effective management, “HAlCHEN”‘s hot chamber as well ascold chamber die-casting machines has won the frust from our clients at home and abroad.

Nozzle manufacturers in die casting in China Common advantages

- High efficiency and energy saving

- Low consumption

- High-quality production

- Multi-mode production

High efficiency and energy saving

Compared with the traditional vertical spray gun, the robot spray system is highly efficient and energy-saving, shortens the mold repair time, and can recover the investment cost within three years.

Low consumption

The use of well-known brand atomization nozzles saves more release agent than traditional copper tube spraying, and can save more than 20% of the loss of release agent.

High-quality production

The robot spray system can achieve high-quality production.

For example,the sintering of the release agent on the surface of the finished product is light.

And the adhesion to the mold is small, which effectively improves the qualified rate of the finished product and saves the labor cost of the mold maintenance site.

Multi-mode production

Each nozzle is controlled by an independent solenoid valve.

And the spraying position and trajectory can be selected programmically to adapt to the production of diversified die-casting products, with high efficiency.

Haichen technical advantages

Abrasion resistant and high thermal conductivity material applications

The inner wall of the nozzle is made of powder metallurgy wear-resistant materials.

Such as tungsten steel alloy to resist the erosion of high-temperature molten metal.

Besides,the nozzle uses a copper alloy with high thermal conductivity to improve heat exchange efficiency.

Modular design

The nozzle assembly can be quickly disassembled and replaced (e.g. screw-in construction) to fit different die-casting models and reduce maintenance costs.