Common troubleshooting for heating bush issues in die casting includes checking for electrical faults, ensuring proper lubrication, verifying thermal insulation, and inspecting for wear and tear to maintain optimal performance and prevent defects.

In the die – casting industry, the heating bush is a critical component that ensures proper temperature control and efficient operation of the die – casting machine.

Maintaining optimal performance of the heating bush is essential for ensuring high – quality production and minimizing downtime.

This article will provide a comprehensive guide on common troubleshooting techniques for heating bush issues, ensuring that die – casting operations run smoothly and efficiently.

By understanding and addressing these common issues, manufacturers can enhance the reliability and longevity of their equipment, ultimately improving overall production efficiency.

Common Issues with Heating Bush

- Temperature Fluctuations

- Inconsistent Heating

- Overheating

Temperature Fluctuations

One of the most common issues with the heating bush is temperature fluctuations. These can occur due to inconsistent power supply, damaged heating elements, or poor insulation.

Inconsistent Heating

Inconsistent heating can lead to uneven metal flow and defects in the final product. This issue may arise from worn – out heating elements or improper installation of the heating bush.

Overheating

Overheating can damage the heating bush and reduce its lifespan. It may be caused by a malfunctioning thermostat or excessive power supply.

Troubleshooting Tips

- Check Power Supply

- Inspect Heating Elements

- Verify Insulation

- Calibrate the Thermostat

Check Power Supply

Ensure that the power supply to the heating bush is consistent and within the specified range. Fluctuations in power can lead to temperature variations.

Inspect Heating Elements

Regularly inspect the heating elements for signs of wear or damage. Replace any damaged elements promptly to maintain consistent heating.

Verify Insulation

Ensure that the insulation around the heating bush is intact. Poor insulation can lead to heat loss and temperature fluctuations.

Calibrate the Thermostat

Calibrate the thermostat regularly to ensure accurate temperature control. A malfunctioning thermostat can cause overheating or insufficient heating.

Maintenance and Prevention

- Regular Maintenance

- Use High – Quality Components

- Monitor Temperature

Regular Maintenance

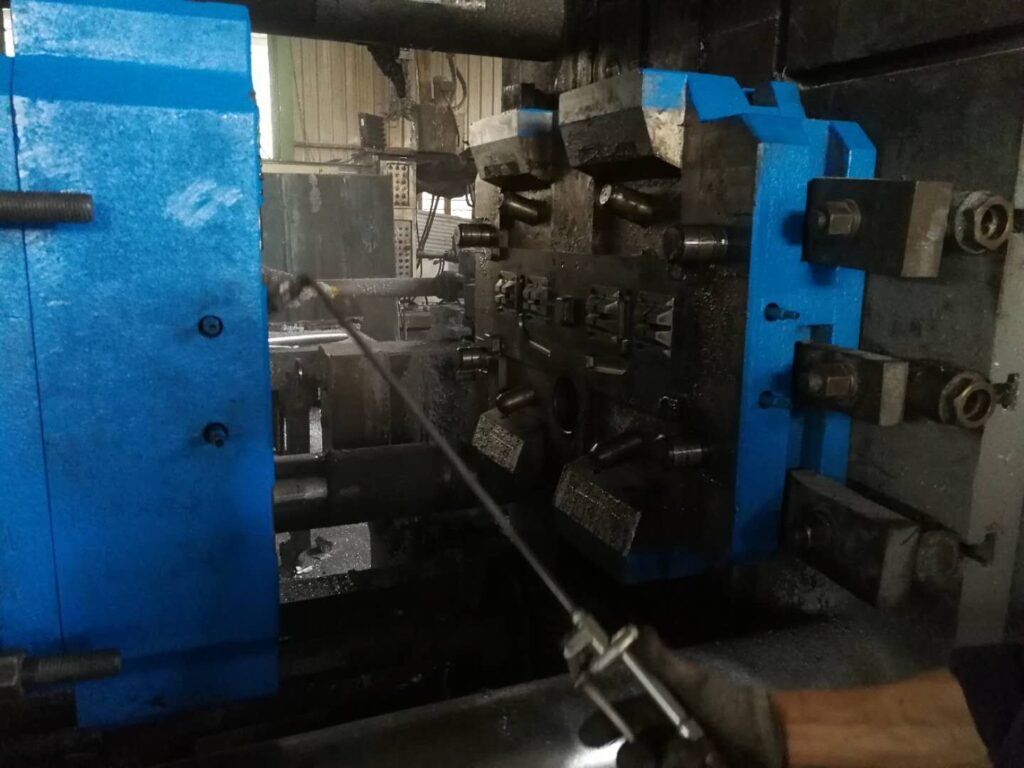

Perform regular maintenance on the heating bush, including cleaning and inspection. This can help identify potential issues before they become critical.

Use High – Quality Components

Invest in high – quality heating elements and insulation materials. These components can withstand the harsh conditions of the die casting process and provide reliable performance.

Monitor Temperature

Continuously monitor the temperature of the heating bush during operation. Use advanced monitoring systems to detect any deviations from the set temperature.

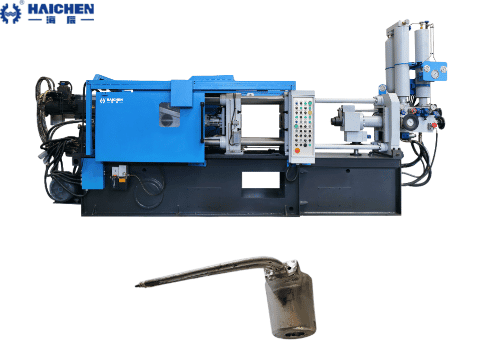

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines equipped with reliable heating systems. Our machines are designed to provide precise temperature control and consistent performance, ensuring high – quality castings. Whether you need assistance with troubleshooting or advice on maintenance, our team of experts is here to support you.

Maintaining the heating bush is essential for efficient and high – quality die casting production. By understanding common issues and implementing effective Heating Bush Troubleshooting in Casting practices, you can ensure optimal performance and longevity of the heating bush.