To select heating bush in die casting mainly includes material and application, evaluate the heating requirements, assess the durability and maintenance.

Heating bush plays a critical role in die casting by maintaining optimal mold temperatures, ensuring consistent part quality, and reducing cycle times.

Selecting the right heating bush improves efficiency, extends mold life, and minimizes defects. Here’s a comprehensive guide to help you make the best choice.

We will discuss How to select Heating bush in die casting mainly from below four aspects:

- Types of Heating Bushes

- Heating bushes Material and Application

- Evaluate the Heating Requirements

- Assess the Durability and Maintenance

Types of Heating Bushes

Heating bushes come in various types, each with its own advantages and applications. Common types include:

High-frequency induction heating bush

This type uses electromagnetic induction to heat the metal quickly and efficiently. It is ideal for applications requiring precise temperature control and rapid heating.

Electric heating bush

These are powered by electrical resistance heating elements. They are suitable for a wide range of temperatures and are generally easy to install and maintain.

Hot runner heating bush

Used primarily in injection molding, these heating bushes help maintain a consistent temperature throughout the runner system, reducing material waste and improving part quality.

Heating bushes Material and Application

The material you are casting and the specific requirements of your application will significantly influence your choice of heating bush. For example:

Aluminum die casting

High-frequency induction heating bushes are often preferred due to their ability to provide rapid and uniform heating.

Zinc or magnesium die casting

Electric heating bushes may be more suitable, as they can offer precise temperature control over a wide range.

Evaluate the Heating Requirements

Determine the specific heating requirements for your die casting process

Temperature range

Ensure the heating bush can achieve and maintain the required temperature for your material.

Heating speed

Consider how quickly the bush can heat the metal. High-frequency induction heating bushes are known for their rapid heating capabilities.

Energy efficiency

Choose a heating bush that offers good energy efficiency to reduce operational costs over time.

Assess the Durability and Maintenance

The durability and ease of maintenance of the heating bush are critical factors:

Material quality

High-quality materials will ensure the heating bush can withstand the harsh conditions of the die casting environment.

Maintenance requirements

Opt for a heating bush that is easy to clean and maintain. Some types may require more frequent maintenance, which can impact production efficiency.

Consult with Suppliers and Experts

Each die casting operation has unique requirements. Consulting with suppliers and experts can provide valuable insights and recommendations. They can help you select the right heating bush based on your specific needs and ensure it is compatible with your existing equipment.

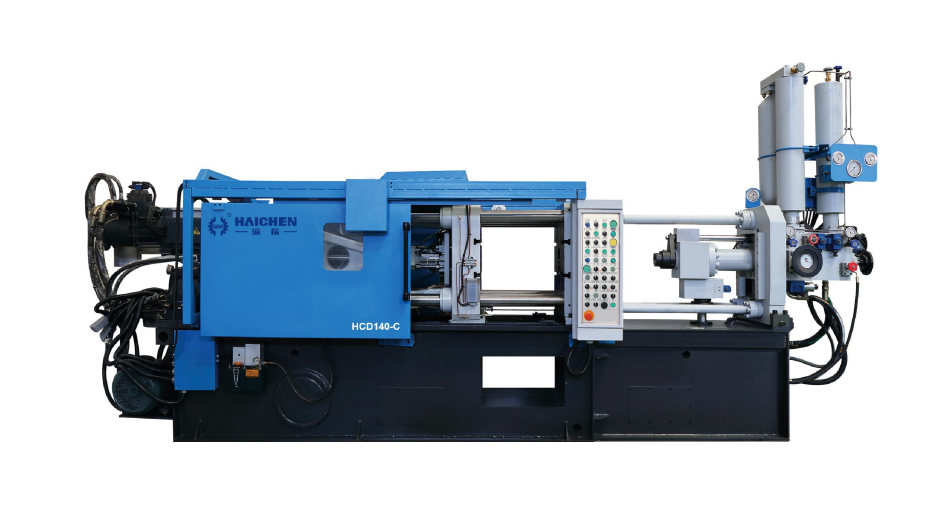

Haichen die casting machine heating bush

Haichen (Haichen) is a professional die casting machine manufacturer offering cold chamber and hot chamber die casting machines. Its products are suitable for die casting of aluminum, zinc, lead and other materials. Besides the machines, we also supply spear parts inclduing heating bush.

Selecting the right heating bush improves die casting efficiency, part quality, and mold longevity. By considering heating capacity, material, size, and control compatibility, you can optimize performance and reduce downtime.

Welcome to consult us for more information.