Heating bush solutions for die casting machines requires a combination of structural design, material science, intelligent control and precision manufacturing technology.

A heating bushing is a critical component used in thermal management, primarily for heat dissipation, temperature control, or heating applications.

A heat pipe is an efficient heat transfer element that typically has a much higher heat transfer efficiency than traditional heat exchangers.

Because it utilizes phase transitions such as liquid evaporation and condensation to achieve efficient heat transfer.

The basic function and structural design of the Heating bush solutions

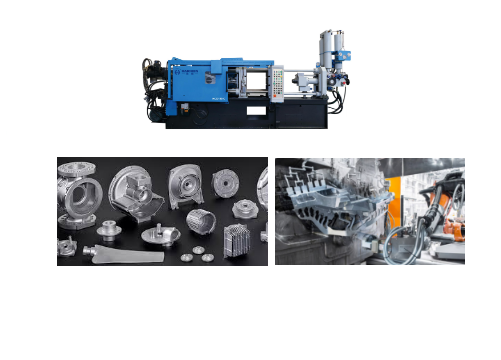

- Cold chamber die-casting machine

- Hot chamber die casting machine

The die casting system mainly uses the heating bushing to maintain the molten metal’s temperature in the pressure chamber or injection tube, ensuring its fluidity and filling performance.

According to the difference between cold chamber and hot chamber die casting machine.

Cold chamber die-casting machine

The chamber needs to compensate for the heat loss of molten metal by means of an external heating element (such as an electric heating rod).

For example, a cold chamber die-casting machine installs a heating rod with a round hole around the circumference of the chamber, and combines the sealing ring and the end cap to form a closed-loop temperature control system.

Hot chamber die casting machine

The heating bushing is in direct contact with the molten metal and requires the integration of a heating element (e.g. an electric heating wire) and a temperature sensor.

The system adopts a double-layer combined cover structure (integrated with electric heating wires A/B), and the power unit adjusts the heating power to achieve precise temperature control.

In some hot chamber die-casting machines, cross-beam energy storage optimizes the stability of the electric heating system.

Technical roadmap and innovative solutions

- Composite Heating Structure

- Modular Combination Cover

- Intelligent control

- Material Innovation

- Ceramic coatings

Composite Heating Structure

Use three layers of concentric tubes the outer tube features high thermal conductivity to eliminate temperature differences and enhance thermal efficiency with induction coils or Caterpillar heaters.

Modular Combination Cover

Renjiezhu’s patented solution uses a symmetrical combination cover to form a cylinder and a round tube, and the gap-matched piston column dynamically adjusts the heating area.

Intelligent control

Siemens PLC system and intelligent interface automate parameter setting.

Such as the digital control module of Haichen die-casting machine.

Which can adjust the heating temperature and injection speed in real time.

In the patent of Haichen cooling system, the cooling water flow and impurities are dynamically monitored through a testing mechanism.

Including a conical filter screen and a pressure sensing module) to optimize the heating-cooling synergy efficiency.

Material Innovation

Metal Substrate: Rene41 alloy (nickel-based superalloy) outperforms traditional materials.

Such as AISI 4130 at high temperatures, and has significant resistance to plastic deformation and wear.

QAl10-4-4 aluminium bronze has been aged at 950°C and 670°C to take into account strength and toughness.

Ceramic coatings

Al₂O₃ ceramic bushings show potential in trial casting, but the problem of coating peeling still needs to be solved.

Silicon carbide (SiC) bushings need to be installed at 600°F temperatures to reduce the risk of chipping.

Heating bush solutions——installation and maintenance

- Graphite bushing

- Silicon carbide bushings

- High temperature interference fit

Graphite bushing

It is necessary to use an off-shaft press to maintain continuous pressure.

To avoid fragmentation, ensure that pressure interruption during installation does not occur, and verify post-installation component integrity.

Silicon carbide bushings

Operators preheat metal parts to 600°F (best in an oven) and quickly locate them using differences in thermal expansion coefficients.

High temperature interference fit

The carbon graphite bushing needs to be heated to 750°F and then pressed in.

And the temperature is not enough to cause cracking.

Maintenance strategy

- Regular inspection

- Wear management

- Hot chamber cleaning

Regular inspection

Lubricate the moving pair after every 800 times of die-casting, clean the slide and steel belt every month, and overhaul the cooling system pipes every year.

Wear management

Submerge bronze alloy or PTFE bushings in lubricating fluids during use, and replace any shaft showing signs of looseness.

Hot chamber cleaning

Metal slag and oxides are removed during shutdown, and the crucible is rotated 120° to evenly heat and avoid local corrosion.

Industry trends and future directions

- Intelligent upgrade

- Lightweight design

- Composite treatment technology

- Green manufacturing

Intelligent upgrade

All-electric servo drive systems gradually replace hydraulic drives, reducing energy consumption and improving temperature control accuracy.

Lightweight design

Racing engineers use nickel-based electrolytic coating on aluminum alloy AA2618 bushings to adapt to strength and thermal expansion requirements in high-performance applications.

Composite treatment technology

Nitriding oxidation composite coating improves corrosion resistance, but the problem of coating peeling needs to be solved.

Green manufacturing

The promotion of cooling water circulation systems and low-pollution coatings.

Such as protective coatings to reduce the environmental load.

Maintenance & Troubleshooting Programs

- Cleaning

- Inspection

- Uneven heating

- Temperature control failure

- Upgrade suggestion

Cleaning

Cleaning the carbon deposits in the heating layer every 500 cycles, using compressed air to purge the heating wire gap.

Inspection

The temperature control probe is calibrated once a month and needs to be replaced if the deviation exceeds ±5°C.

Uneven heating

Check whether the heating layer is broken, or the insulation layer is damaged and causes heat leakage.

Temperature control failure

Check the loose wiring of the thermocouple or the fault of the controller module.

And upgrade the intelligent temperature control box if necessary.

Upgrade suggestion

Manufacturers use induction heating to replace traditional electric heating, and this technology reduces energy consumption by 25%-40%, making it especially suitable for continuous production scenarios.