Materials used for casting ladles cup mainly includes: metallic materials, ceramic materials, composite refractory castables, carbonaceous materials and so on.

Casting ladles cup is typically made from a variety of materials to suit different casting requirements. Casting ladles play a crucial role in metal foundries, transporting molten metal from furnaces to molds.

The choice of materials depends on the molten metal type (iron, steel, aluminum, etc.), temperature, and casting process. High-performance refractories like alumina, zirconia, and silicon carbide are essential for longevity, while the steel shell provides structural support. Proper maintenance of the refractory lining is crucial for ladle performance and safety.

Common materials are used for casting ladles cup

The materials used for their construction must withstand extreme temperatures, thermal shock, and chemical corrosion. Here are the common materials casting ladle components.

Steel (Mild Steel or Carbon Steel)

The outer shell is typically made of welded or riveted steel plates for structural strength.

Stainless Steel (for some applications)

Offers better corrosion resistance, especially in non-ferrous foundries.

Ladle Body (Shell) of casting ladles cup

Heat-resistant steel, cast steel, and cast iron

Common materials include heat-resistant steel, cast steel, or cast iron, requiring a refractory lining to prevent metal adhesion and heat loss.

Shell steel plate of casting ladles cup

The shell is typically welded from boiler steel plates, with a wall thickness of 14-30mm and a bottom thickness of 24-40mm, and ventilation holes are drilled in the shell.

Material property data of casting ladles cup

Parameters such as the coefficient of thermal expansion, density, and modulus of elasticity of the shell material indicate that it is a high-strength steel (density approximately 7.8g/cm³, modulus of elasticity approximately 175GPa).

Carbon-molybdenum alloy steel

In large steel casting cups, the shell often uses carbon-molybdenum alloy steel (UNSK11820) to meet high-temperature strength requirements.

Ductile cast iron

In the casting cups of high-pressure die-casting machines, ductile cast iron is often used to obtain better strength and toughness.

Refractory Lining (Inner Layer) of casting ladles cup

The inner lining must resist molten metal erosion and thermal shock. Common refractory materials include:

Fireclay (Alumina-Silicate)

Economical and suitable for lower-temperature metals (e.g., aluminum, bronze).

High-Alumina Refractories

Better resistance to iron and steel casting.

- Silica (SiO₂) Bricks: Used for acidic slags.

- Magnesite (MgO) or Dolomite (CaO-MgO): Used for basic slags in steel foundries.

- Zirconia (ZrO₂) or Silicon Carbide (SiC): High-performance linings for extreme conditions.

- Graphite or Carbon-Based LiningsZ: Used in some specialty applications.

Nozzle & Pouring Spout

- Ceramic Nozzles (Alumina, Zirconia, Silicon Carbide) : Resistant to molten metal wear.

- Refractory Cement or Precast Shapes: Used to form smooth pouring channels.

- Ladle Coating (Wash)

- Refractory Coatings (e.g., Bentonite, Graphite, or Zircon-based): Applied to the inner lining to reduce metal sticking and improve durability.

Handle & Mechanical Parts

- Steel or Reinforced Steel: For strength and heat resistance.

- Wood (for smaller hand ladles): Insulates against heat but is less durable.

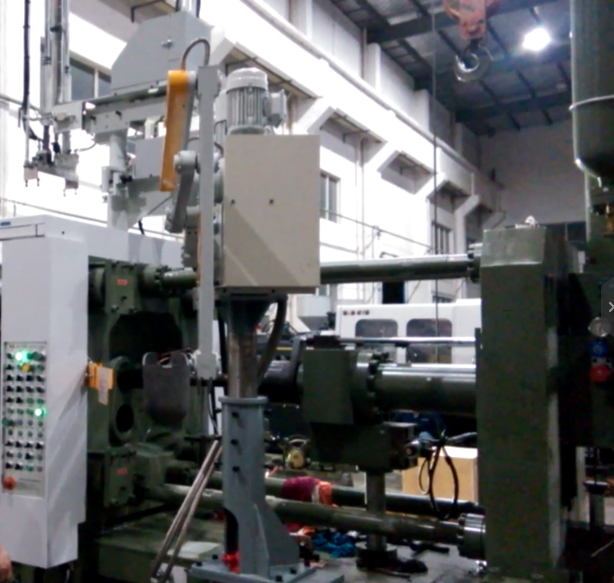

Casting ladles cup: Haichen Machinery

Haichen Machinery is a well-known manufacturer of die-casting equipment, including die-casting ladles (pouring ladles or dosing furnaces) used for transferring molten metal (typically aluminum, zinc, or magnesium alloys) into cold chamber die-casting machines. Our ladles provide precision, efficiency, and durability in high-pressure die-casting (HPDC) operations.

The Haichen Die Casting Ladle Cup offers several advantages that enhance the efficiency and quality of the die casting process:

High-Quality Materials

Haichen Die Casting Ladle Cups are made from durable materials such as ductile cast iron, which provides excellent wear resistance and a hardness of 45-50 HRC. This material ensures that the ladle cups can withstand the high temperatures and repeated use associated with die casting operations.

Minimized Heat Loss and Oxidation

The ladle cups can minimize heat loss and exposure of molten metal to air. This reduces oxidation and the formation of defects in the cast product. The preheating and insulation features of the ladle cups help maintain the optimal temperature of the molten metal during the casting process.

Long Service Life

The ladle cups are built to last, with a service life of over 5000 uses. This longevity reduces the frequency of replacements and maintenance, lowering overall production costs.

If there is any demand for die casting ladles cup, welcome to consult us.