Die casting is a manufacturing process known for producing high-precision,and efficient can produce high-precision metal parts.

Conventional process of die casting

- Definition of Die Casting

- Key Process Steps

- Advantages and Limitations

- Typical Applications

- Technological Trends

Definition of Die Casting

Die casting forces molten metal under high pressure into a reusable steel mold (a “die”). The process rapidly solidifies the metal into high-precision, complex-shaped parts. Manufacturers favor this method for its high efficiency, superior surface finish, and suitability for mass production.

Key Process Steps

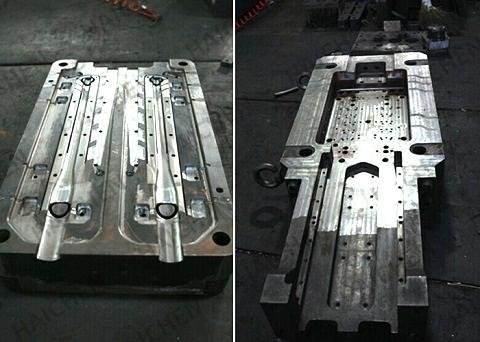

- Die Preparation

- Operators coat the two die halves (fixed and moving) with water-based lubricants or release agents to prevent sticking and extend tool life.

- Heating systems (e.g., gas torches) regulate die temperature to avoid premature metal solidification or thermal stress damage.

- For thin-walled or deep-cavity areas, workers often apply solid lubricants for added protection .

- Clamping

- Hydraulic systems clamp the die halves with forces ranging from 100 to 4,000 tons, adjusted based on part size and metal type to prevent deformation.

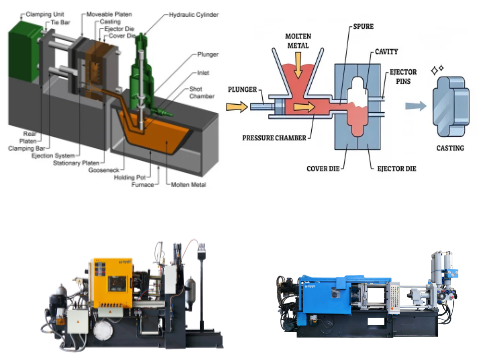

- Melting and Injection

- Factories commonly use aluminum (lightweight), zinc (high fluidity), and magnesium (high strength), melting them at specific temperatures (Al: ~660°C, Zn: ~420°C).

- Cold-chamber systems inject high-melting-point metals, while hot-chamber machines handle low-melting-point alloys. The process applies 100–150 MPa pressure to fill intricate cavities fully.

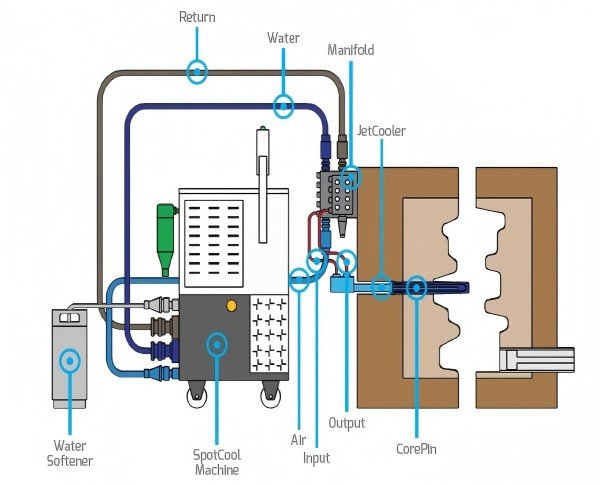

- Cooling and Solidification

- The die cools the metal within seconds to minutes, depending on material, wall thickness, and temperature.

- Built-in cooling channels optimize heat distribution, minimizing porosity defects.

- Ejection

- Automated systems open the die and activate ejector pins to remove the part, carefully controlling force to avoid distortion.

- Post-Processing

- Trimming tools or CNC machines remove gates and flash.

- Surface treatments like anodizing (for aluminum corrosion resistance) or electroplating enhance functionality and aesthetics.

Advantages and Limitations

Advantages:

- One-minute cycle times support high-volume production.

- ±0.1 mm dimensional accuracy and Ra 0.8–3.2 μm surface finishes minimize post-processing.

- The method produces complex thin-walled parts (down to 0.5 mm thickness).

Limitations:

- High tooling costs (CNC-machined steel dies) make small batches cost-ineffective.

- Material restrictions exclude high-melting-point metals like steel.

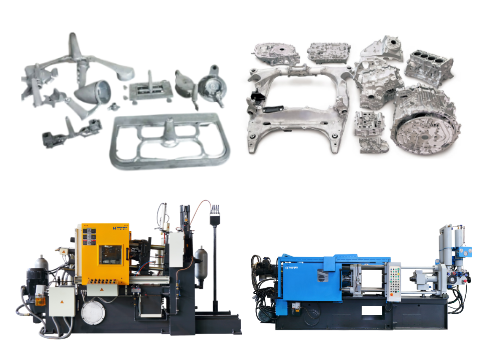

Typical Applications

- Automotive: Engine blocks, transmission housings.

- Consumer Electronics: Smartphone frames, heat sinks.

- Aerospace: Drone components (Light Metal Age, 2022).

Technological Trends

- Vacuum Die Casting removes trapped air for denser parts.

- CAE Simulation predicts metal flow to refine die designs.

- Semi-Solid Die Casting merges forging and casting benefits.

This streamlined process continues to dominate precision manufacturing by balancing speed, cost, and quality.

How does die casting work step by step?

Die Casting Process: Step-by-Step

- Mold Preparation

- Clean the mold surfaces to remove residue or contaminants.

- Apply a lubricant (e.g., mold release agent), often mixed with water, to the mold cavity. This helps regulate mold temperature and ensures smooth part ejection. The water evaporates upon contact with the heated mold, leaving a thin protective film.

- Clamping

- Hydraulic systems tightly clamp the two mold halves (fixed and moving halves) under high pressure (ranging from hundreds to thousands of tons, depending on machine size). This prevents molten metal from leaking during injection. Precision alignment is critical.

- Melting & Injection

- Metal alloys (e.g., aluminum, zinc, magnesium) are melted in a furnace (600–700°C for aluminum).

- Cold-Chamber Process (for high-melting-point metals): Molten metal is ladled into a shot chamber, then injected into the mold via a piston at extreme pressures (up to 20,000 psi).

- Hot-Chamber Process (for low-melting-point metals like zinc): A gooseneck submerged in molten metal directly injects the material into the mold.

- Cooling & Solidification

- The mold remains clamped under pressure as the metal cools and solidifies. Cooling time depends on part thickness, alloy type, and mold temperature. Pressure is maintained to minimize shrinkage and porosity.

- Ejection

- After solidification, the mold opens, and ejector pins or plates push the casting out of the cavity. Sensors ensure precise timing to avoid part deformation.

- Trimming & Finishing

- Excess material (e.g., gates, flash, overflow) is removed using trimming presses, saws, or CNC machines.

- Secondary processes like CNC machining, anodizing (for aluminum), electroplating, or powder coating may enhance surface quality or functionality.

Key Considerations

- Mold Design: Made from high-strength steel (e.g., H13 or P20 tool steel) to withstand thermal stress. Preheating molds to 150–250°C optimizes flow and reduces defects.

- Cycle Time: Ranges from seconds for small parts to minutes for large components.

- Environmental & Safety: Fume extraction systems handle harmful gases (e.g., zinc oxide); operators wear heat-resistant PPE.

- Applications: Ideal for mass-producing complex, thin-walled parts (e.g., automotive engine blocks, smartphone frames, hardware components).

Die casting achieves high dimensional accuracy, excellent surface finishes, and production speeds of up to hundreds of parts per hour, making it a cornerstone of modern manufacturing.

Operation process of die casting machine

The operation process of a die casting machine can be divided into the following key steps, with variations depending on the type of machine:

- Mold Preparation and Preheating

- Metal Melting and Feeding

- Mold Clamping

- Injection Phase

- Pressure Holding and Cooling

- Mold Opening and Ejection

- Post-Processing

Mold Preparation and Preheating

- Mold Installation: Secure the mold onto the machine, aligning it with positioning systems. Preheating the mold (typically to 150–300°C) extends its lifespan and optimizes metal flow.

- Lubricant/Release Agent Application: Spray lubricant or release agent onto the mold surface to prevent metal adhesion and aid cooling. Timing varies (pre- or post-mold closure).

Metal Melting and Feeding

- Alloy Melting: Melt metals (e.g., aluminum, zinc) in a furnace to a liquid state, ensuring precise alloy ratios (e.g., ADC12 aluminum).

- Cold Chamber Machines: Molten metal is manually or mechanically ladled into the injection chamber.

- Hot Chamber Machines: The injection chamber is submerged in the molten metal, which automatically fills via a gooseneck channel.

Mold Clamping

- Clamping Force: Hydraulic systems apply high clamping force (e.g., 1,000–50,000 kN) to tightly seal the mold and withstand injection pressure.

Injection Phase

- Slow Injection: The plunger pushes molten metal at low speed (0.1–0.5 m/s) to evacuate air from the chamber, reducing porosity.

- Rapid Injection: High-speed injection (2–10 m/s) fills the mold cavity quickly to minimize premature solidification.

- Intensification Phase: Additional pressure (1,000–20,000 psi) compensates for shrinkage during solidification, enhancing part density.

Pressure Holding and Cooling

- Pressure Holding: Maintain pressure until the metal fully solidifies (time varies with part thickness and material).

- Cooling: Built-in cooling channels or external sprays accelerate heat dissipation for dimensional stability.

Mold Opening and Ejection

- Mold Separation: Hydraulic systems open the mold vertically (vertical machines) or horizontally (horizontal machines).

- Part Ejection: Ejector pins or robotic arms remove the casting without damage.

Post-Processing

- Trimming: Remove gates, flash, and burrs using trimming presses or manual tools.

- Inspection: Check for defects (e.g., porosity, shrinkage) via visual inspection, X-ray, or CT scanning. Qualified parts are cleaned and packaged.

Differences Between Die Casting Machine Types

- Hot Chamber Machines: Ideal for low-melting-point alloys (zinc, magnesium). Faster cycle times but higher maintenance due to molten metal exposure.

- Cold Chamber Machines: Suitable for high-melting-point alloys (aluminum, copper). Slower but more robust for heavy-duty applications.

Automation and Control

- PLC Systems: Programmable logic controllers (PLCs) manage parameters (temperature, pressure, speed) via HMIs (Human-Machine Interfaces).

- Multi-Stage Injection: Modern machines use proportional valves for precise control of slow/rapid injection and intensification phases.

Safety and Maintenance

- Safety Protocols: Safety doors, emergency stops, and interlocks prevent accidents during operation.

- Maintenance: Regularly check hydraulic oil cleanliness, lubricate moving parts, and monitor electrical components. Optimal hydraulic oil temperature: 20–45°C.

Die casting enables high-volume production of complex, precision parts for industries like automotive, electronics, and aerospace.

Welcome to contact us at any time to get more details of die casting process.