The 4 steps of high pressure die casting include mold preparation, metal injection, cooling and solidification, and part ejection.

High – pressure die casting (HPDC) is a widely used manufacturing process in the metal – casting industry, known for its ability to produce complex parts with high precision and efficiency.

This process is favored by manufacturers worldwide due to its versatility and the high – quality results it consistently delivers.

In this article, we will delve into the 4 steps of high pressure die casting and explain how each step contributes to the production of high – quality parts.

Additionally, we will explore the importance of advanced technologies and best practices in optimizing the HPDC process for maximum efficiency and part quality.

Mold Preparation and Spraying

- Process Description

- How to Promote High-Quality Part Production

Process Description

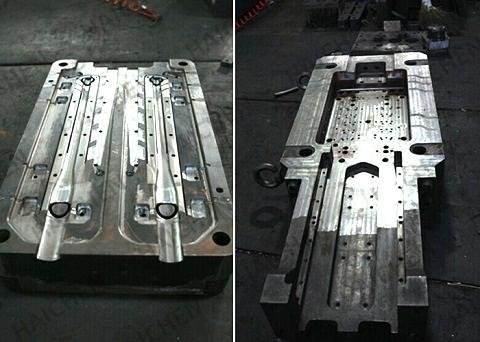

Before the cycle begins, the precision mold, consisting of two halves, the fixed and movable mold, must be prepared. After the molds are closed, a release agent is sprayed into the mold cavity, often accompanied by an air blow-off step.

How to Promote High-Quality Part Production

- Ensuring Smooth Mold Release: The core function of the release agent is to form a barrier film on the mold surface. Preventing the molten metal from adhering to the mold steel under high pressure, thereby ensuring that the casting can be released intact when the mold is opened.

- Controlling Mold Temperature: The water-based solution in the release agent evaporates rapidly upon contact with the hot mold, dissipating a significant amount of heat and assisting in cooling. This helps maintain a stable, optimal mold temperature, preventing overheating that can lead to defects such as shrinkage cavities and thermal cracks on the casting surface, and extending mold life.

- Improving Surface Quality: Uniform spraying is key to achieving a smooth, uniform casting surface. Uneven spraying can lead to localized sticking or cold shuts, seriously affecting appearance and dimensional accuracy.

A stable and efficient die-casting machine is essential for ensuring precise mold closing and stable operation of the spraying system. The robust clamping mechanism of HAICHEN die-casting machines ensures perfect parallelism between the molds, creating optimal conditions for uniform spraying.

Metal Injection and Filling

- Process Description

- How it contributes to high-quality part production

Process Description

This is the most critical and dynamic stage in the process. A metering spoon pours a precisely measured amount of molten metal (typically an aluminum, magnesium, or zinc alloy) into the die chamber. The shot punch then pushes the molten metal through the gating system at extremely fast speeds (typically in just tens of milliseconds), rapidly filling the entire die cavity.

How it contributes to high-quality part production

- Creating a dense surface layer: High-speed filling ensures that the molten metal solidifies rapidly upon contact with the cold die wall, forming a dense, smooth “skin.” This skin directly contributes to the excellent surface finish and dimensional accuracy of the casting.

- Replicating Intricate Details: Extremely high flow rates enable the molten metal to perfectly replicate the finest textures and structures in the mold, enabling the production of extremely complex, thin-walled parts.

- Preventing Defects: Precisely controlled injection profiles avoid turbulence and air entrainment. If the injection speed is too slow, the molten metal will solidify prematurely. Resulting in defects such as “cold shut” or “under-gush.”

Our die-casting machines are equipped with advanced, real-time, closed-loop shot control systems. It precisely controls the speed and pressure of the punch at different stages. Achieving “slow sealing” to expel air from the pressure chamber before switching to “high-speed filling” to ensure that the molten metal fills the mold cavity in optimal conditions. This is a prerequisite for producing high-quality internal structure castings.

Pressurization and Solidification

- Process Description

- How to Promote High-Quality Part Production

Process Description

The moment the mold cavity is filled with molten metal. The injection system immediately applies an extremely high final pressure (up to hundreds or even thousands of bar). This pressure is continuously appliy to the solidifying casting through the gating system.

How to Promote High-Quality Part Production

- Shrinkage Compensation: Metal shrinks in volume as it transitions from liquid to solid. Continuous high pressure forces the unsolidified molten metal into the shrinkage zone. Effectively preventing shrinkage cavities and porosity within the casting.

- Improving Internal Density: Pressurization is key to achieving high-performance castings. It densifies the casting’s internal structure, significantly improving its strength, hardness, and airtightness.

- Ensuring Dimensional Stability: By reducing internal porosity, the casting’s dimensional stability is greatly guarante during subsequent processing and use.

The HAICHEN die-casting machine’s powerful pressurization system provides instantaneous, stable, and sufficient clamping force and injection pressure. Ensure that the mold does not expand during the pressurization phase. Allowing pressure to be transfer intact to the core of the casting, achieving perfect “compaction.”

Mold Opening and Ejection

- Process Description

- How to Promote High-Quality Part Production

Process Description

When the casting has cooled to sufficient strength within the mold cavity, the movable mold section retracts, opening the mold. Subsequently, the ejector mechanism (ejector pins or ejector plate) operates to smoothly eject the finished casting from the mold.

How to Promote High-Quality Part Production

- Ensuring Casting Integrity: Precisely controlled cooling time is critical. Too short a cooling time prevents the casting from fully solidifying and causing deformation during ejection. Too long a cooling time reduces production efficiency and places excessive pressure on the mold, potentially causing ejection difficulties or damage.

- Avoiding Ejection Marks: Smooth, synchronized ejection prevents uneven force from causing deformation, whitening, or visible ejector pin marks, all of which can become defects requiring subsequent repair.

- Achieving Automation and Efficiency: A stable and reliable ejection system is the cornerstone of a fully automate production cycle. Robots can accurately remove parts after this step and move on to the next cycle.

Our machines are equipped with precise ejection control and adjustable ejection speed and stroke to ensure accurate ejection every time. Furthermore, efficient and stable hydraulic systems and high-rigidity mold plates ensure fast and smooth mold opening and closing, maximizing production efficiency.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines designed for precision and efficiency. Our machines feature advanced technology to ensure consistent performance and high – quality production. Whether you are starting a new project or upgrading your existing equipment, HAICHEN has the solutions to meet your needs.

Customer Case: How HAICHEN’s Solution Adds Value in the 4 Steps

A customer using a HAICHEN 650T machine to make a 280mm aluminum fry pan shows how our equipment works through all four HPDC steps to solve real problems. The pan had thin walls (2.8mm) and a large size. The challenge was to fill it fast with a perfect surface. Our solution ensured even spraying through precise clamping; the servo injection used an optimized 3-stage curve to prevent cold shuts; fast intensification fed shrinkage in the thicker base; and the smooth ejection system allowed for robotic handling. The result was a stable cycle time under 45 seconds and a product yield rate over 98.5%.

Understanding the four steps of high pressure die casting is essential for achieving high – quality and efficient production. By mastering each step, manufacturers can produce complex metal parts with precision and reliability.