Die casting overflow do includes vent and reduce oxidation, control molten metal flow, maintain mold temperature uniformity etc.

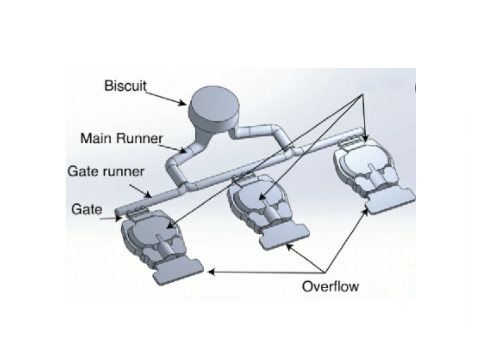

The overflow port of the die casting machine is a precisely designed auxiliary cavity system in the mold. Its core functions are exhaust, slag collection, flow control and heat preservation, which directly determines the integrity of the casting.

The role of die casting overflow mainly reflect in the following aspects:

- Venting and reduce oxidation

- Control the flow of molten metal

- Maintain mold temperature uniformity

- Prevent defects and improve casting quality

- Adapt to different process requirements

- Reduce energy waste

Venting and reduce oxidation

During the die casting process, molten metal fills the mold cavity under high pressure. And the gas in the cavity needs exhaust through the exhaust system.

Overflow wells are usually designed at the edge of the mold to guide the flow of molten metal. And help gas to escape from the mold, thereby reducing the formation of oxides and improving the quality of the casting.

Exhausting Cavity Gas

- Overflow grooves, by connecting to vent channels or exhaust grooves, provide an escape path for gases within the mold cavity. During melt filling, gases are drawn into the overflow grooves and discharged through them, reducing porosity and gas entrapment.

- If the overflow groove is improperly positioned (e.g., away from the melt confluence point), gases cannot be fully discharged, resulting in localized high-pressure areas (>2500 mbar) and the formation of porosity defects.

Optimizing Vent Path Design

- Overflow grooves should be combined with thin-walled vent channels (0.004-0.007 inch thickness): The initial thickness (1/64-1/32 inch) allows a small amount of melt to fill and solidify, forming a “gas barrier.” Subsequent gases are discharged only through a thin gap.

- Overflow grooves should be located at the final melt filling point (e.g., where multiple melt streams converge) to ensure that gases are pushed to the end of the cavity for discharge.

Collecting Oxidized Melt

- The overflow trough acts as a “metal oxide container,” collecting the initial injection of melt (which is severely oxidized due to contact with air) and condensed metal at the front, preventing it from entering the main casting.

- Optimizing the overflow trough volume is crucial: if it is too small, it will not be able to accommodate sufficient oxidized metal, resulting in oxide residue in the casting.

Controlling Melt Flow

- Reducing Flow Rate: Increasing the cross-sectional area at the overflow trough connection reduces the melt flow rate and avoids turbulence that can lead to increased oxidation (especially for aluminum and magnesium alloys).

- Smooth Filling: Adjusting the injection speed ensures that the melt fills the cavity smoothly, minimizing splashing and oxidation.

Control the flow of molten metal

The design of overflow wells helps control the flow path of molten metal to ensure that the metal can evenly fill the mold cavity.

For example, overflow wells can guide molten metal around difficult-to-fill areas to avoid defects caused by underfilling or condensation.

Directing Metal Flow

Overflow troughs are typically located at the end of mold filling or at metal confluence points. They contain excess molten metal and guide the main flow, ensuring uniform filling of the cavity.

For example, placing overflow troughs in difficult-to-fill areas (such as those near thin walls or complex structures) can help prevent undercasting or cold shut defects.

Venting and Porosity Reduction

The overflow and vent grooves form a comprehensive venting system, allowing gases and lubricant volatiles to escape from the cavity, reducing porosity and oxide inclusions.

Contains impurities and cold metal

Serving as an auxiliary cavity, the overflow trough collects cold slag, scale, and cold metal at the leading edge of the melt.

Preventing these from entering the main casting and causing defects (such as cold shuts or inclusions).

Maintain mold temperature uniformity

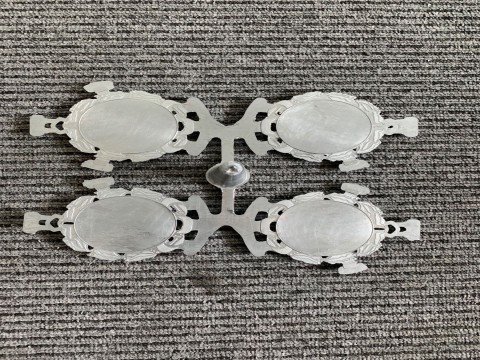

In small castings, overflow wells can increase the total mass of molten metal, thereby helping to maintain mold temperature uniformity.

This helps reduce condensation defects caused by uneven temperature, such as cold welding, that is, the molten metal fails to fully fuse.

Increasing Molten Metal Mass to Balance Heat Capacity

Overflow wells increase the total metal mass of small or thin-walled castings by capturing excess molten metal.

Optimize overflow port location and design

Location selection: Overflow ports should be located in low-temperature areas of the mold, at the end of the molten metal filling process, or where multiple streams of metal meet to specifically increase the local temperature.

Dimensional Design

The overflow is typically thinner than the main runner, and should be designed to be less than long to prevent backflow of molten metal.

Prevent defects and improve casting quality

The design of the overflow well can reduce pores and defects inside the casting.

For example, by reasonably designing the overflow port and the exhaust groove, gas residue and residual porosity can be effectively avoided. Thereby improving the overall quality of the casting.

Collects impurities and gases, reducing internal defects

- Purpose: The overflow trough serves as an auxiliary cavity, specifically collecting cold slag, scale, and gases at the leading edge of the molten metal.

- Preventing these impurities from entering the main casting and causing defects such as porosity and inclusions.

Improves thermal balance and prevents cold shuts and flow marks

Purpose:

The overflow trough acts as a heat source, raising the mold end temperature and preventing cold shuts and flow marks caused by premature solidification of the molten metal.

Promotes filling integrity and reduces undercasting

Function: The overflow groove relieves back pressure in the cavity, guiding the molten metal to completely fill the distal area and prevent undercasting.

Adapt to different process requirements

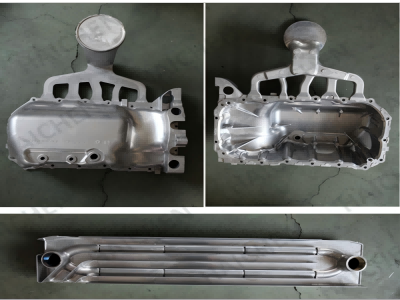

In high-pressure casting (such as semi-solid casting), the design of the overflow well is particularly important.

Because it can help control the fluidity of the molten metal, reduce pre-crystallization. And condensation defects, and thus improve the mechanical properties and surface quality of the casting.

Collecting Impurities and Exhausting Gas

The overflow trough serves as an auxiliary cavity, specifically collecting cold slag, scale, and gases from the leading edge of the molten metal.

Preventing impurities from entering the main cavity and affecting casting quality.

Thermal Balance Regulation

The overflow tank acts as a “heat accumulator,” regulating local temperature through volume design:

Reduce energy waste

In some cases, the overflow valve can be used to recycle excess hydraulic oil, thereby reducing energy waste. This design has certain significance in terms of energy saving and environmental protection.

Overflow plays a vital role in the die casting process, including venting, controlling metal flow, maintaining mold temperature, optimizing mold design and improving casting quality. These functions work together to ensure high-quality production of castings.

Optimize overflow chute design to reduce material consumption

- Accurately calculate overflow volume: Overly large overflow chute volumes can lead to metal waste (overflow material can account for over 40% of thin-walled castings).

- Minimize excess metal by properly designing its location and volume (e.g., placing it at the end of the molten metal filling).

Scrap Recovery and Recycling

Metal Scrap Regeneration

Overflow tank waste is remelted and directly reused, reducing energy consumption in raw material mining and refining.

Reduced Secondary Processing

Optimizing overflow design reduces the need for subsequent trimming and machining, indirectly reducing energy waste.