Addressing die casting overflow involves optimizing mold design to ensure proper venting, adjusting injection speed and pressure to prevent excess material flow, and maintaining consistent cooling to solidify the metal quickly and evenly.

Die casting overflow, or flash, occurs in the die casting operation when excess molten metal spills out of the mold cavity, turning into unwanted features on the component.

This can result in defects, higher rates of material loss, and increased post-processing work.

It is important to understand the causes of die casting overflow to implement effective solutions in order to maintain production quality and operational efficiency.

This article delves into the overflow of die casting and provides actionable measures to address the problem to achieve perpetual part quality and streamline the manufacturing processes.

Definition and Core Functions of Die Casting Overflows

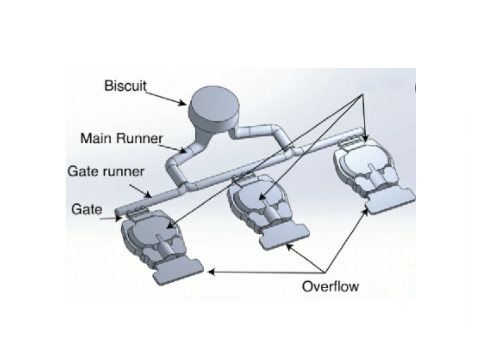

Overflows in die casting have auxiliary structures to the main mold cavity, in the form of overflow and exhaust grooves. Their core functions include:

- Defect and Gas Inclusion: Prevents the inclusion of cold material, oxide inclusions, and gases at the interface region of the molten metal in order to improve casting quality by reducing porosity and shrinkage defects.

- Balancing Mold Temperature: The excess molten metal provides a thermal buffer which reduces cold shuts and flow marks resulting from temperature imbalances in the region.

- Metal Flow Guidance: Prevents turbulence and air trapping when multiple streams of metal merge.

- Ejection Assistance: Certain overflow grooves reduce the likelihood of casting distortion by functioning as ejection aids.

Solution of Die Casting Overflow

Focus on the design and additional aspects to enhance the effectiveness of overflow die casting:

- Optimize Overflow Design

- Enhance Venting Systems of Die casting Overflow

- Control Metal Flow

- Improve Die Design and Maintenance

- Use Advanced Techniques

- Preventive Measures

Optimize Overflow Design

- Positioning: Overflow grooves should be positione toward the terminal portion of the pathway of metal flow and at the junction of the converging streams. This helps in capturing the excess metal and the trapped gases efficiently.

- Form and Dimension: Overflow grooves should be designe to have forms. Which facilitate the easy filling and easy removal of excess metal. Common shapes include half circles and trapezoids. The size of the overflow should accommodate the volume of excess metal likely to be generated.

Enhance Venting Systems of Die casting Overflow

- Vent Channels: Make sure that the overflow system has adequate vent channels to allow the escape of the trapped air which aids in reducing the porosity, thus improving the quality of the casting.

- Exhaust Grooves: Integrate exhaust grooves with overflow grooves to ensure that the entire venting system supports proper metal flow through the system with minimal gas entrapment.

Control Metal Flow

- Injection Speed: Relating to injection speed, it is critical to maintain smooth orderly injection to reduce turbulence as well as the creation of gas pockets.

- Temperature Management: Metal temperatures need to be consistent and optimal to reduce the risk of cold shuts, while still allowing for proper filling and solidification.

Improve Die Design and Maintenance

- Die Temperature: To reduce the risk of shrinkage and other solidification defects, dial in optimal die temperatures to ensure no premature cooling and uniform solidification.

- Regular Maintenance: Regularly maintained dies need to be clear of contaminants to ensure proper gas venting. Regularly inspect and repair all worn and damaged die parts.

Use Advanced Techniques

- Simulation Tools: Predictive numerical simulation will identify and solve overflow system design problems. This will optimize overflow groove placement.

- 3D Printing: 3D Printing improvements to mold design will greatly increase precision and flexibility for the overflow system, optimizing die casting operations.

Preventive Measures

- Proper Gate and Runner Design: Avoiding turbulent flow of metal during the filling of the mold through the gates and runners greatly reduces the risk of defects thus improving the casting quality.

- Regular Monitoring: Quality can be maintained across different production runs through real-time monitoring and automation of the casting process.

Haichen die casting solutions

The Company specializes in providing Haichen high-quality die casting solutions with modern manufacturing technologies, precise tools, and optimized processes to boost production efficiency and quality of the final products. We mainly supply cold chamber and hot chamber die casting machines. The following die casting problems, including overflow defects, are addressed with the key solutions Haichen provides.

Advanced Mold Design & Engineering

- Optimized Overflow Wells: Designed to capture the excess molten metal and minimize defects.

- Enhanced Venting Systems: Better air and gas escape to decrease the porosity and overflow.

- Precision Gating & Runner Systems: Guarantees smooth metal flow, thus reducing turbulence and spillage.

Process Optimization

- Injection Parameters Controlled: Speed and pressure are set to prevent overfilling.

- Temperature Management: Guarantees die and molten metals are at optimal temperature for flow.

- Monitoring in real-time: Overflow risks are detected and corrected with the aid of sensors and automation.

Defect Prevention & Quality Control

- X-Ray & Ultrasonic Testing: Detects internal defects caused by improper overflow.

- Strict Process Standards: Follows ISO-certified procedures for consistency.

- Post-Casting Trimming: Removes excess material efficiently.

HAICHEN: Systematic Solutions for Overflow Issues

Overflow problems often come from a mismatch between the mold, process, and machine. HAICHEN offers a full-system solution, from mold review to process tuning and smart monitoring, to prevent and fix overflow defects.

- Mold-Process Co-Design Support

- High-Dynamic Injection Process Control

- Case Study: Fixing Overflow on an Aluminum Fry Pan Rim

Mold-Process Co-Design Support

Early in a project, HAICHEN engineers can join mold design reviews. We focus on overflow wells and vent systems. Using flow simulation software, we predict where the metal flow ends and where air might get trapped. We help customers optimize the placement, size, and vent connections of overflow wells. This makes sure they trap cold metal and let gas escape properly.

High-Dynamic Injection Process Control

Overflow often happens when pressure is not controlled at the end of filling. HAICHEN die casting machines have high-performance servo injection systems. They allow precise multi-stage control of speed and pressure. By setting exact slowdown and intensification points, the metal flow slows down smoothly right as the cavity fills. Then, the accumulator gives a precise final pressure. This prevents over-pressure that forces metal out through vents, causing flash.

Case Study: Fixing Overflow on an Aluminum Fry Pan Rim

A cookware maker had consistent uneven overflow around the top rim of a 280mm aluminum fry pan. This led to high grinding costs.

- Problem Analysis: Our team found the original mold’s overflow wells were too small. The injection process used only one high speed, causing a pressure surge when metal hit the thin pan rim.

- Solution:

- Mold Change: We advised adding 12 small overflow wells around the rim and deepening the vent channels.

- Process Tuning: On the HAICHEN 650T machine, we changed the injection to a 3-stage curve: “high-speed fill – end slowdown – low-pressure intensify”. This reduced the end impact.

- Temperature Control: We improved cooling for the mold core around the rim to make that area solidify faster and stronger.

- Result: The rim overflow was eliminated. The first-pass yield rate rose from 89% to 97%. The grinding work needed later dropped by 70%, greatly cutting total cost.

Die casting overflow is a common issue that can be addressed through proper mold design, optimized injection parameters, careful material management, and regular maintenance. By implementing these solutions, manufacturers can reduce the occurrence of overflow, improve part quality, and enhance overall production efficiency.