Die Casting Overflow is a small chamber in molds that collects excess molten metal to ensure consistent casting quality.

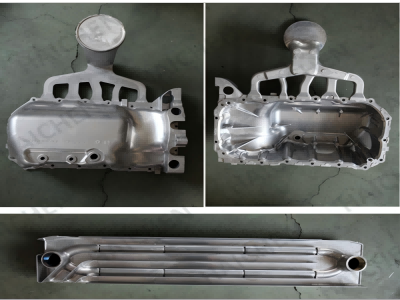

Die casting is a precision manufacturing process used to produce complex metal parts by injecting molten metal into a mold cavity under high pressure.

One common feature in die casting molds is the overflow, which plays a crucial role in ensuring the quality and consistency of the final product.

This article will explore what die casting overflow is and its significance in the die casting process.

Definition of Die Casting Overflow

The die casting overflow, also known as an overflow cavity, connects to the main mold cavity as a small chamber. Its primary function is to collect excess molten metal during the injection process. This excess metal is often the result of fluctuations in the injection pressure or volume, and the overflow ensures that this excess does not interfere with the main casting.

Function of Die Casting Overflow

- Ensuring Consistent Fill

- Reducing Defects

- Enhancing Mold Life

Ensuring Consistent Fill

The overflow helps ensure that the main mold cavity is filled consistently and completely. By providing a place for excess metal to go, it prevents the formation of voids or incomplete fillings in the final part.

Reducing Defects

Overflow cavities can help reduce defects such as porosity and inclusions. By capturing excess metal, they prevent these impurities from becoming trapped in the final casting, leading to higher – quality parts.

Enhancing Mold Life

By reducing the pressure on the mold walls, the overflow can help extend the life of the mold. This is particularly important in high – volume production runs where mold wear can be a significant issue.

Design Considerations

- Size and Shape

- Placement

- Material and Cooling

Size and Shape

The size and shape of the overflow cavity are critical for its effectiveness. It must be large enough to collect excess metal but not so large that it wastes material or affects the overall mold design.

Placement

The placement of the overflow cavity is also important. The mold designer should position the overflow to capture excess metal without disrupting the flow into the main cavity. Typically, they place it at the end of the flow path.

Material and Cooling

Designers should use materials for the overflow cavity and its cooling system that can withstand the high temperatures and pressures of the die casting process. Effective cooling allows the excess metal to solidify quickly, enabling easy removal.

HAICHEN’s Practice in Overflow Optimization

The effectiveness of overflow wells depends heavily on the coordination between the mold, process, and die casting machine. Leveraging deep understanding of the die casting process chain, HAICHEN provides integrated solutions from mold design review to production parameter optimization, ensuring the overflow system performs at its best.

- Collaborative Mold Design and Simulation Verification

- Precise Process Parameter Matching

- Case Study: Improving Aluminum Fry Pan Production

Collaborative Mold Design and Simulation Verification

Early in a project, HAICHEN engineers can participate in mold design reviews. Using flow simulation software, we analyze how the metal fills the cavity and identify the flow ends. We help customers decide the right number, size, and location for overflow wells. For complex thin-wall parts, for example, we suggest placing overflows at the flow end and where two metal streams meet, to trap cold material and vent air effectively.

Precise Process Parameter Matching

The function of overflow wells is closely tied to injection settings. HAICHEN die casting machines feature high-performance servo injection systems that allow precise multi-stage control of speed and pressure. By setting the right switch points for low speed and intensification, we ensure the metal fills smoothly and pushes the cold front material into the overflow wells at the right moment. This maximizes the overflow’s role in collecting impurities and improving surface finish.

Case Study: Improving Aluminum Fry Pan Production

A customer producing 280mm aluminum fry pans on a HAICHEN 650T machine faced cold shuts and flow marks on the pan rim.

- Problem Analysis: We found the original mold’s overflow wells were too small and poorly placed. They failed to collect the cold, oxidized metal at the end of the fill.

- HAICHEN Solution:

- Mold Modification Advice: We guided the customer to add 8 small overflow wells evenly around the top rim and improved the vent channels.

- Process Tuning: Using the machine’s multi-stage injection control, we reduced the fill-end speed by 30% and slightly increased the pressure at that stage to gently push cold material into the overflows.

- Temperature Management: We adjusted the mold temperature in that area to promote directional solidification.

- Result: After the changes, cold shuts and flow marks on the rim were eliminated. The surface quality improved significantly. The first-pass yield rate increased from 88% to 96%. Material waste did not increase thanks to the well-designed overflow system.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines designed for precision and efficiency. Our machines are equipped with advanced features that ensure consistent performance and high – quality production. Whether you are starting a new project or upgrading your existing equipment, HAICHEN has the solutions to meet your needs.

Understanding the role of die casting overflow is essential for achieving high – quality and efficient production. By providing a place for excess metal to go, the overflow helps ensure consistent fill, reduces defects, and enhances mold life.