A hydraulic directional control valve works by selectively allowing or blocking the flow of hydraulic fluid to control the direction of fluid flow within a hydraulic system, enabling precise control over the movement of actuators such as cylinders and motors.

In the world of die casting, hydraulic systems play a crucial role in controlling the movement and pressure of molten metal.

These systems ensure that the molten metal is injected into the mold with precision and consistency, which is vital for producing high-quality parts.

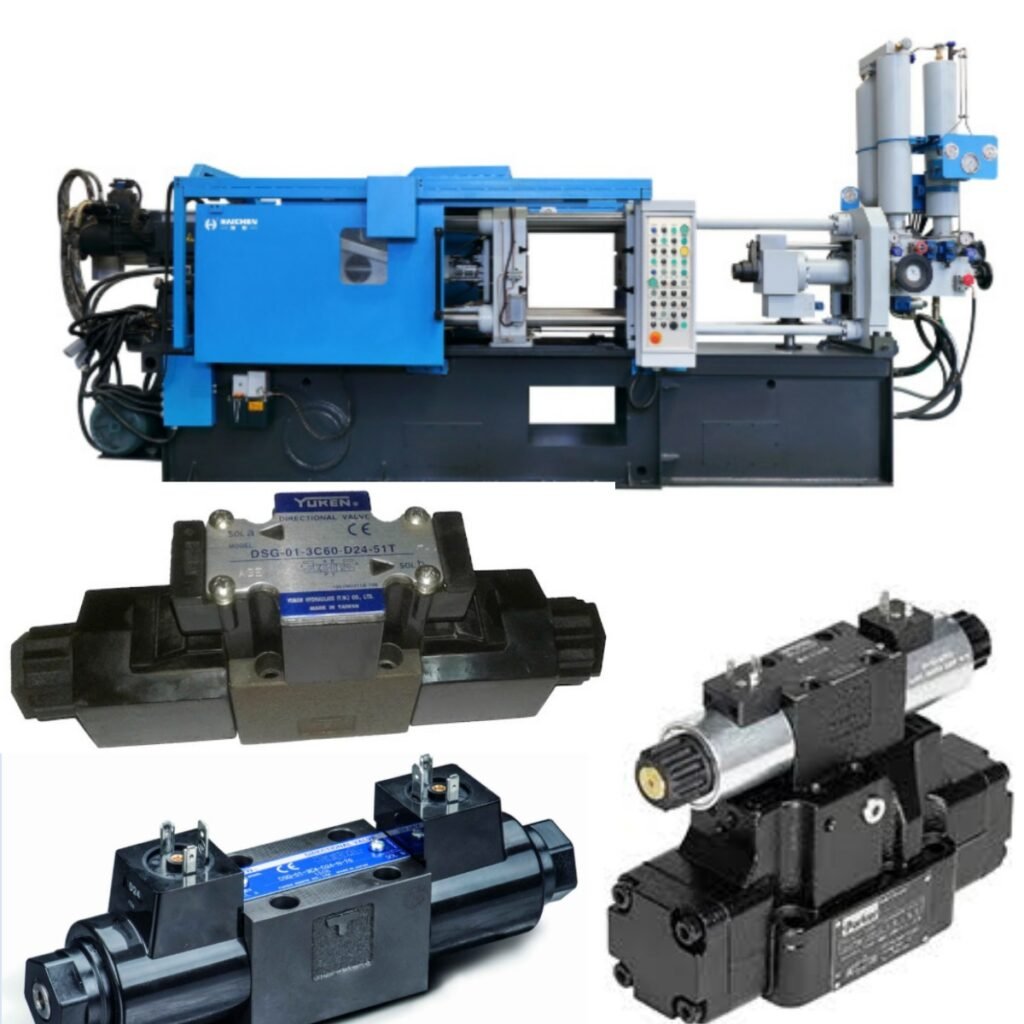

A key component of these systems is the hydraulic directional control valve. This valve is responsible for managing the flow and direction of hydraulic fluid. Enabling the precise control of hydraulic actuators such as cylinders and motors.

Understanding how this valve works is essential for maintaining efficient and precise operations.

In this article, we will explain the workings of a hydraulic directional control valve and its importance in die casting.

Basic Function

A hydraulic directional control valve is design to control the direction of hydraulic fluid flow within a system. It allows fluid to be directed to different parts of the machine, enabling precise control over the movement of components. Such as the injection unit and mold clamping system.

Components of the Valve

- Valve Body

- Spool or Slider

- Ports

Valve Body

The valve body is the main structure that houses the internal components of the valve. It is typically made from durable materials to withstand high – pressure hydraulic fluid.

Spool or Slider

The spool or slider is a movable part within the valve body that controls the flow of hydraulic fluid. By shifting its position, the spool can open or close passages, directing fluid to different parts of the system.

Ports

Ports are openings in the valve body that connect to the hydraulic lines. They allow hydraulic fluid to enter and exit the valve, facilitating the flow of fluid to various components of the machine.

How It Works

The hydraulic system moves the control valve’s spool or slider when activated. This movement opens or closes specific passages within the valve body, allowing hydraulic fluid to flow in a particular direction. For example, in a die casting machine. The valve can direct fluid to the injection unit to initiate the injection process or to the mold clamping system to secure the mold during casting.

Haichen Technology Practice:

Haichen die-casting machines utilize high-performance electro-hydraulic proportional directional valves integrated into their intelligent hydraulic system.

In actual operation, Haichen’s control system sends precise electrical signals to drive the valve core to a predetermined position. This action precisely opens or closes the oil circuits to actuators such as the mold clamping cylinder and the injection cylinder.

For example, during high-speed injection, Haichen’s system ensures extremely rapid response and switching of the directional valve, precisely guiding the high-pressure oil flow to the injection cylinder, thereby achieving smooth and high-speed filling of molten metal. This is crucial for producing die-cast parts such as aluminum pots with extremely high surface quality requirements. Haichen’s intelligent control system can also monitor and fine-tune the valve core position in real time, ensuring repeatability and process stability.

Hydraulic Directional Control Valve Work

Applications in Die – Casting

In die – casting machines, hydraulic directional control valves are used to control the movement of the plunger, the mold, and other hydraulic actuators.

For example, during the injection phase, the valve directs hydraulic fluid to the plunger cylinder, causing the plunger to move and inject molten metal into the mold.

During the mold opening and closing operations, the valve controls the flow of fluid to the mold – actuating cylinders, ensuring precise and synchronized movement.

Importance in Die Casting

In die casting, precise control over hydraulic fluid flow is essential for maintaining consistent injection pressure and speed, as well as ensuring proper mold clamping. The hydraulic directional control valve allows for these adjustments, contributing to high – quality castings and efficient production.

Maintenance and Care

Proper maintenance of hydraulic directional control valves is essential for their reliable operation. Regular inspection and cleaning of the valve components help prevent contamination and wear.Timely replacement of worn parts ensures optimal performance.

At HAICHEN, we provide comprehensive maintenance guidelines and support to help our customers keep their hydraulic systems in top – notch condition.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines equipped with reliable hydraulic systems. Our hydraulic directional control valves deliver precision and durability, maintaining consistent performance in your die casting operations. Whether you are starting a new project or upgrading your existing equipment, HAICHEN has the solutions to meet your needs.

Understanding how a hydraulic directional control valve works is crucial for maintaining efficient and precise die casting operations. Mastering the Hydraulic Directional Control Valve Work allows for precise control over machine movements by directing hydraulic fluid flow, ensuring high – quality castings.