Die Casting is a manufacturing process that produces metal parts by injecting molten metal into a mold cavity at high pressure.

In this process, the application of force is crucial, mainly including injection force, locking force, and ejector force.

Force casting in die casting is the core element, which runs through the key links.

Such as metal filling, mold locking, and ejection and mold removal.

Definition and principle of Force Casting

Force Casting is not a stand-alone process, but rather a comprehensive system of technologies that apply pressure to molten metal in the die casting process to achieve efficient molding.

Injection Force: The hydraulic oil pushes the injection plunger to inject the metal melt into the mold cavity at high pressure (15–500 MPa).

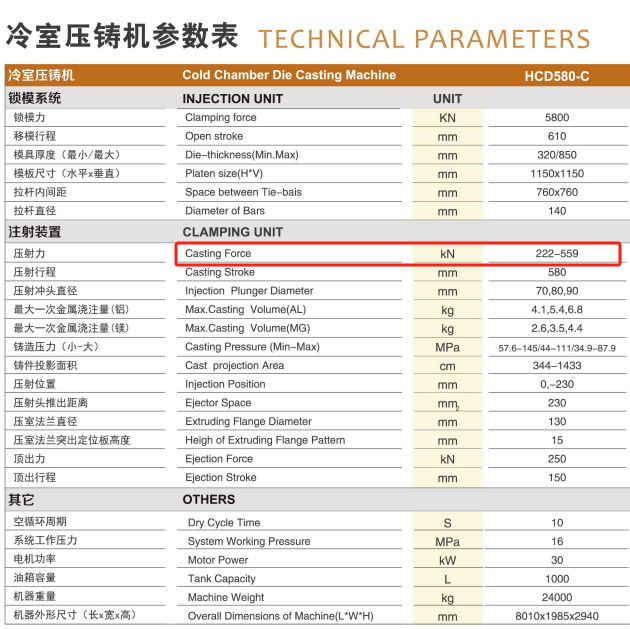

The size of the injection force depends on the size of the die casting machine.

Which directly affects the filling speed and metal flow.

Clamping Force: Used to overcome the expansion force of molten metal in the mold cavity and ensure that the mold closes under high pressure.

Ejector Force: The force exerted by the ejector pin during demoulding needs to be precisely controlled to avoid casting deformation or mold damage.

Key parameters and force control technology

- Specific Pressure

- Intensification

- Ejector force measurement and calibration

Specific Pressure

Defined as the ratio of the injection force to the cross-sectional area of the plunger.

Which affects the compactness of the metal fill.

High specific pressures (e.g., 90 MPa) reduce porosity, but balance clamping force with equipment costs.

Intensification

During the solidification phase of the metal, a pressurized accumulator maintains high pressure.

Thereby compensating for shrinkage and improving the mechanical properties of the casting.

Ejector force measurement and calibration

Piezoelectric sensors are used to monitor the ejector force distribution in real time, and in-situ calibration.

Such as shock load calibration, ensures data accuracy and optimizes the demoulding process.

The role of ejection force in the die casting stage

- Slow Sealing Phase

- Filling stage

- Pressurization stage

- Holding phase

Slow Sealing Phase

The ejection force is used to overcome the frictional resistance between the chamber and the punch.

Ensuring that the molten metal enters the front of the chamber smoothly and avoids splashing and gas entrapment.

At this time, the specific pressure is low (about 1-5 MPa).

Filling stage

The injection force rises rapidly (about 50-100MPa), breaks through the inner gate resistance, and fills the cavity with high speed (0.5-70m/s).

At this stage, the specific pressure directly affects the fluidity and filling integrity of the metal.

Pressurization stage

After the completion of the molten metal filling, the pressurization mechanism is started.

And the injection force reaches the peak (the specific pressure of the pressurization can reach 100-300MPa).

Which compensates for the solidification shrinkage and reduces the shrinkage porosity.

The pressurization response time needs to be extremely short (<0.04s) to ensure compaction.

Holding phase

The ejection force continues to act on the solidified metal, ensuring that the internal structure of the casting is dense until it is completely solidified.

Effect of ejection force on the quality of the casting

- Pore defects

- Optimization strategy

- Shrinkage porosity and porosity

- Surface quality and mechanical properties

Pore defects

High-speed injection (>5m/s) can easily lead to turbulent gas entrapment, forming pores with a diameter of 0.1-1mm, reducing mechanical properties and air tightness.

Optimization strategy

By adjusting the slow injection speed to 0.2-0.8 m/s, researchers effectively reduced initial gas entrapment.

Furthermore, the implementation of a uniform acceleration injection curve ensured smooth gas discharge through controlled velocity progression.

Shrinkage porosity and porosity

When the specific pressure of the pressurization is insufficient, the molten metal cannot compensate for the solidification shrinkage, resulting in internal shrinkage.

Studies have shown that the boost pressure needs to reach 1.5-2 times of the filling specific pressure to effectively compensate.

Surface quality and mechanical properties

High specific pressures can refine grains, increase density, and increase tensile strength (about 10-20%), but may reduce elongation.

Extreme high pressure (>300MPa) can lead to flash and sticking, shortening the life of the mold.

The specific application scenarios of Force Casting in die casting

- Production of complex thin-walled parts

- Vacuum Die Casting

- Local pressurization technique

- Electromagnetic Centrifugal Casting

Production of complex thin-walled parts

The high-pressure injection force allows the filling of thin-walled structures below 0.5 mm.

Which is widely used in precision parts such as automobile engine blocks and transmission housings.

Vacuum Die Casting

The reduction of cavity gases by vacuuming, combined with high-pressure injection (e.g. aluminum-magnesium alloys).

Significantly reduces porosity and allows castings to be heat-treated (e.g. in the case of the Audi A2 B-pillar).

Local pressurization technique

To mitigate shrinkage porosity from solidification and shrinkage, the thick-walled area undergoes separate pressurization, thus enhancing the casting’s density.

Electromagnetic Centrifugal Casting

Combines centrifugal and electromagnetic forces to optimize metal distribution (e.g., coating mold applications) and reduce impurity segregation.

The future trend of jet force control

- Intelligent control

- Energy-saving design

- Material adaptability expansion

Intelligent control

Based on machine learning algorithms to predict the optimal injection force parameters, combined with real-time feedback from sensors.

Dynamic optimization is achieved (e.g., the injection force fluctuation is controlled within ±2%).

Energy-saving design

The servo-hydraulic system controls the injection force and the clamping force together.

Reducing energy consumption by more than 40% and improving the response speed (acceleration >50G).

Material adaptability expansion

For new materials such as magnesium alloy and high-silicon aluminum, customized injection force curves are developed to solve the filling problem of high-viscosity metals.