Die casting machine accumulator failure analysis : material fatigue, thermal fatigue, fluctuate hydraulic system pressure and aging of seals.

Failure analysis of accumulators in cold chamber die casting machines can discuss from multiple perspectives. Including their working principles, common causes of failure, and possible solutions.

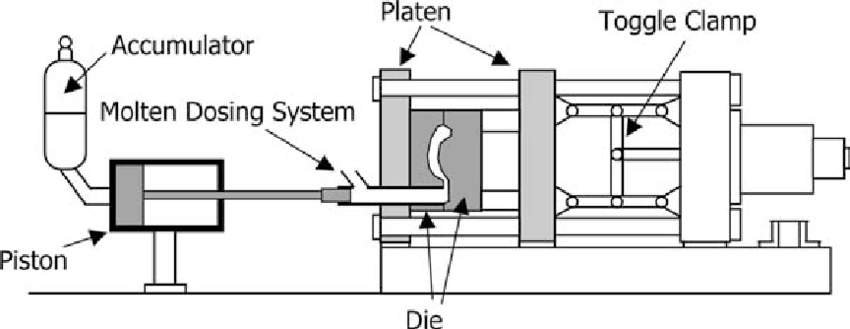

Accumulators are auxiliary energy storage devices in hydraulic systems that store hydraulic energy to cope with system pressure fluctuations. In cold chamber die casting machines, accumulators store high-pressure hydraulic oil to compensate for fluctuations in the hydraulic system, thereby providing additional power and flow during peak demand.

Causes of accumulator failure in cold chamber die casting machines may caused by the following reasons:

- Die casting machine accumulator failure analysis: thermal fatigue

- Material fatigue of die casting machine accumulator failure analysis

- Hydraulic system pressure fluctuations

- Aging of seals

- Solution of solve the problem of accumulator failure

Die casting machine accumulator failure analysis: thermal fatigue

- Thermal fatigue dominates

- Crack propagation process

- Key factors affecting fatigue life

The accumulator is subjected to high temperature cyclic stress in the cold chamber die casting machine, which may cause thermal fatigue cracks. Studies have shown that thermal fatigue is one of the main causes of mold and tool failure, especially in the cold chamber die casting process of aluminum and copper alloys.

The accumulator repeatedly charges and discharges under high pressure, which may cause material fatigue. For example, high melting point metals such as aluminum, copper and magnesium alloys are susceptible to high temperature cyclic fatigue during cold chamber die casting, which may cause cracks or damage on the accumulator surface.

Thermal fatigue dominates

During the die-casting process, the accumulator mold repeatedly undergoes rapid hot and cold cycles (molten metal contact → cooling), resulting in thermal stress on the surface and inside. When the stress exceeds the material yield limit, it will cause local plastic deformation, accumulating to form microcracks (thermal fatigue cracking).

The thermal fatigue is the most important failure form of die-casting molds, accounting for 70% of failure cases.

Crack propagation process

- Stage 1 (crack initiation): Thermal stress causes irreversible damage to the material structure, and microcracks initiate from surface defects (such as manufacturing defects or oxidation points).

- Stage 2 (crack propagation): Molten metal penetrates into the crack, and combined with mechanical pressure accelerates crack propagation; at the same time, oxidation corrosion reduces the fatigue strength of the material and further promotes crack growth.

- Stage 3 (final fracture): When the crack depth reaches the critical value, the mold breaks instantly.

Key factors affecting fatigue life

Number of cycles and damage accumulation

Simulations of AISI H11 tool steel show that fatigue damage increases exponentially with the number of cycles.

Temperature gradient and thermal stress

- The higher the temperature of the molten metal (e.g., copper alloy die casting temperature reaches 1090°C), the greater the temperature difference between the mold surface and the inside, the more significant the thermal stress generated, and accelerates thermal fatigue.

- Tensile stress induced during the cooling stage (e.g., spray lubrication) further exacerbates crack propagation.

Dependence on material properties

- Thermophysical properties: Materials with low thermal expansion coefficient, high thermal conductivity, and high high temperature strength (such as optimized H13 steel) can delay thermal fatigue

- Lack of toughness: Brittle materials are prone to sudden fracture (the so-called “brittle cracking”).

- Surface treatment: Laser bionic coupling strengthening of the surface can inhibit crack initiation.

Material fatigue of die casting machine accumulator failure analysis

- Cyclic loading leads to damage accumulation

- Dominant failure mode

- Aggravating factors

- Impurities and inclusions

- Material performance requirements

Cyclic loading leads to damage accumulation

- the material undergoes irreversible structural changes under repeated stress, and fatigue damage increases exponentially with the number of cycles.

- Three-stage failure process: including crack initiation (microcracks form at material defects), crack propagation (stress concentration accelerates propagation) and final fracture.

Dominant failure mode

70% of die casting mold failures are caused by thermal fatigue, which is caused by the alternating hot and cold cycles between the molten metal and the mold surface. Thermal stress causes the material surface to yield, triggering microcracks and gradually expanding.

Aggravating factors

Oxidative corrosion and mechanical loads (such as high-pressure metal flow impact) will accelerate the expansion of thermal fatigue cracks and reduce the fatigue strength of the material.

Impurities and inclusions

Hard oxide inclusions (such as Al₂O₃ in steel) become crack initiation points, significantly reducing thermal fatigue resistance. The use of ultra-high purity steel smelting technology can reduce impurities and increase mold life.

Material performance requirements

Materials with low thermal expansion coefficient, high thermal conductivity, and high yield strength (such as H13 steel) can delay thermal fatigue, but are still prone to failure at high temperatures.

Hydraulic system pressure fluctuations

- Pre-charge pressure is too low or lost

- Pre-charge pressure is too high

- Pre-charge pressure does not match system pressure

- Internal leakage or seal failure

- Improper volume design

The main function of the accumulator is to buffer the pressure fluctuations of the hydraulic system. If the hydraulic system doesn’t design properly or maintained properly. It may cause the accumulator subject to abnormal pressure fluctuations, thereby accelerating its damage.

Pre-charge pressure is too low or lost

The accumulator cannot effectively absorb pressure fluctuations, exacerbating system pulsation. If the airbag/diaphragm ruptures, the pre-charge pressure will drop to zero and completely lose the buffering function.

Pre-charge pressure is too high

The piston accumulator hits the hydraulic end cover at the minimum system pressure, causing mechanical damage. At the same time, too high pre-charge pressure will shorten the accumulator stroke and reduce fluid output.

Pre-charge pressure does not match system pressure

If the pre-charge pressure is not adjusted with the system pressure, it will cause the accumulator to fail prematurely.

Internal leakage or seal failure

- Worn piston seal: During rapid cycling, liquid will gradually penetrate into the gas side, causing the pre-charge pressure to continue to rise. When the pre-charge pressure equals the maximum system pressure, the accumulator fails completely.

Bladder/diaphragm rupture: Failure is sudden and unpredictable, as there is no visible leakage before rupture.

Improper volume design

- Accumulator volume is too small: it cannot fully absorb pressure fluctuations, resulting in increased pressure fluctuations in the hydraulic circuit.

- Pre-charge pressure p0 Setting error: p0 the lower the pressure, the more significant the pressure fluctuation.

Aging of seals

- High temperature and thermal cycle effects

- Environmental factors accelerate degradation

- Mechanical stress and wear

- Material and quality issues

The seals inside the accumulator may age due to long-term use, causing hydraulic oil leakage or pressure drop, thus affecting the normal operation of the accumulator. External environmental factors: such as temperature changes, vibrations, etc. may also have an adverse effect on the accumulator, leading to failure.

High temperature and thermal cycle effects

During the operation of the die casting machine, the accumulator is exposed to high temperature (the temperature of the die casting liquid can reach over 660°C), and the seals undergo repeated thermal expansion and contraction. This can cause the molecular chains of the material to break and the elasticity to weaken.

Environmental factors accelerate degradation

UV radiation, humidity, temperature fluctuations and chemical attacks (such as solvents in cooling water or die casting fluids) catalyze the aging process.

Mechanical stress and wear

The accumulator piston moves frequently under high pressure, causing wear and deformation of the seal surface.

Material and quality issues

Improper seal selection or poor quality is a common cause. It is emphasized that if the seal material does not match the actual working conditions (such as insufficient temperature resistance), aging will occur prematurely.

Solution of solve the problem of accumulator failure

- Optimize material selection

- Improve hydraulic system design

- Regularly replace seals

- Strengthen thermal management

- Regular inspection and maintenance

Optimize material selection

Select materials with good high temperature strength and fatigue resistance, such as H13 steel with special heat treatment, which can significantly increase the service life of the accumulator.

Improve hydraulic system design

Ensure the pressure of the hydraulic system is stable, and regularly inspect and maintain the accumulator and its related components to reduce damage caused by pressure fluctuations.

Regularly replace seals

Replace aging or damaged seals in time to prevent hydraulic oil leakage or pressure drop.

Strengthen thermal management

Reduce the operating temperature of the accumulator by improving the cooling system or using more efficient heat dissipation materials, thereby reducing the impact of thermal fatigue.

Regular inspection and maintenance

Regularly inspect the accumulator to detect potential problems in time and repair or replace them.

The failure of cold chamber die casting machine accumulators is usually related to factors such as material fatigue, thermal fatigue, unreasonable hydraulic system design, and seal aging. By optimizing material selection, improving hydraulic system design, strengthening thermal management and regular maintenance. The service life of the accumulator can be effectively extended and the reliability of the system can be improved.

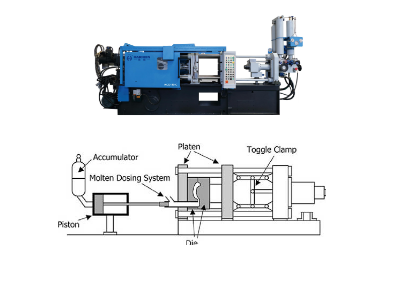

Haichen cold chamber die casting machine

Haichen is one Chinese die casting machine manufacture for more than 10years. They produce cold chamber die casting machines with have durable and highly precise features. The core advantages like following:

- High-performance structures meet demanding processes

- Precise and flexible process control

- Outstanding reliability and durability

High-performance structures meet demanding processes

The Haichen Cold Chamber Die-casting Machine employs a high-strength integral frame and an optimized mold closing system.

Capable of withstanding the extreme internal pressure generated during the die-casting of high-melting-point metals such as aluminum alloy and magnesium alloy. It features high precision and uniform distribution of mold closing force, effectively preventing flash.

Ensuring dimensional stability and internal density for large or structurally complex components (e.g., automotive structural parts and motor housings).

Precise and flexible process control

Equipped with a high-performance servo control system, it achieves multi-stage precise control over injection speed, pressure, and stroke.

This feature is crucial for parts with thin walls, high-surface requirements, or localized reinforcement needs. Through fine-tuning of process parameters, it can significantly reduce scrap rates and improve material utilization.

Outstanding reliability and durability

Key hydraulic and electrical components are sourced from internationally renowned brands, paired with a scientifically designed circulating cooling and filtration system to ensure equipment stability under continuous high-load operation.