Choosing aluminum cookware is primarily based on its excellent overall performance, including superior heat conductivity, light weight, durability, and cost-effective mass production.

This article will explain the core advantages of aluminum cookware in terms of material properties and user experience.

It will analyze how advanced manufacturing processes enable these benefits.

Finally, it will introduce how HAICHEN, as a die casting equipment supplier, provides complete solutions for the large-scale, high-quality production of aluminum cookware.

The reasons to choose aluminum cookware

The main reasons for choosing aluminum cookware include the following:

- Excellent Thermal Conductivity

- Affordability

- Lightweight and Easy to Handle

- Versatility

- Durability and Corrosion Resistance

- Energy Efficiency

- Practicality

Excellent Thermal Conductivity

Aluminum is an excellent thermal conductor, much more so than other common cookware materials (such as stainless steel and iron), and transfers heat quickly and evenly to food. This allows cookware to heat up quickly when cooking, reducing the problem of uneven heating of food, thus improving cooking results.

Affordability

The cookware is highly cost-effective. Compared to materials like stainless steel or copper, aluminum products are generally much cheaper. This makes it an accessible option for those on a budget, such as students or new homeowners.

Lightweight and Easy to Handle

Aluminum is significantly lighter than other cooking materials like cast iron. This makes it easier to handle, especially when full. It is also beneficial for those with limited upper body strength or mobility.

Additionally, its lightweight nature makes it a great choice for outdoor cooking or camping.

Versatility

Aluminum pot is versatile and can be used for a wide range of cooking methods, including frying, baking, steaming, and roasting. Many aluminum pans are compatible with various stovetops, including gas, electric, and even induction (if anodized). This versatility makes it a reliable tool for both novice and experienced cooks.

Durability and Corrosion Resistance

Modern cookware is often anodized, which creates a hardened surface that resists scratches, stains, and corrosion. This treatment extends the lifespan of the cookware and ensures it remains in good condition over time.

Energy Efficiency

Due to its excellent heat conductivity, it requires less energy to heat and maintain cooking temperatures. This not only speeds up the cooking process but also results in lower utility costs. It is also an environmentally friendly choice as it minimizes energy consumption.

Practicality

Aluminum pot is easy to clean and maintain. Anodized aluminum surfaces resist sticking, making cleanup a breeze. Additionally, its affordability means you can easily replace or expand your collection without breaking the bank.

Superior Material and User Performance

The popularity of aluminum cookware first comes from the excellent physical and chemical properties of aluminum itself, which translate directly into a better cooking experience and long-term durability.

- Excellent and Even Heat Conduction

- Light Weight and Ease of Use

- Durability from Surface Treatment

Excellent and Even Heat Conduction

Aluminum is one of the best metals for conducting heat, much better than stainless steel or cast iron. This allows aluminum cookware to respond quickly to heat changes and spread heat fast and evenly across the entire cooking surface. It effectively prevents local burning or uneven cooking, greatly improving results.

Light Weight and Ease of Use

Aluminum has low density, making the finished pots and pans lightweight. This significantly reduces effort during daily cooking and moving pots, especially useful for long handling or pouring. It is also convenient for outdoor activities like camping.

Durability from Surface Treatment

Modern aluminum cookware commonly uses surface treatments like hard anodizing. This process creates a hard, dense layer of aluminum oxide on the surface. It greatly increases surface hardness, wear resistance, and corrosion resistance. The cookware becomes harder to scratch, less likely to stick, and easier to clean, with a much longer service life.

Advantages of Advanced Die Casting Manufacturing

The many benefits of aluminum cookware are achieved on a large scale thanks to high-pressure die casting. This advanced manufacturing process makes full use of aluminum alloy’s properties.

- One-Piece Forming of Complex Structures

- Efficient and Scalable Production Capacity

- Excellent Dimensional Accuracy and Surface Finish

One-Piece Forming of Complex Structures

High-pressure die casting allows complex pot structures with features like reinforcement ribs, cool-touch handles, or specific base patterns to be formed in a single shot. This removes potential weak points or seams from traditional stamping and welding, resulting in stronger, better-looking products with more design freedom for heat distribution.

Efficient and Scalable Production Capacity

Die casting has fast cycle times, measured in seconds per part, and is easy to automate. This enables aluminum cookware to be mass-produced with very high efficiency to meet huge global demand, while maintaining highly competitive unit costs.

Excellent Dimensional Accuracy and Surface Finish

Die casting molds are highly precise, ensuring stable, consistent dimensions for every product. The as-cast surface is smooth, reducing the need for later machining. This provides an excellent base for high-quality surface treatments, directly improving the final product’s look and feel.

Aluminum cookware supplier: Haichen Machinery

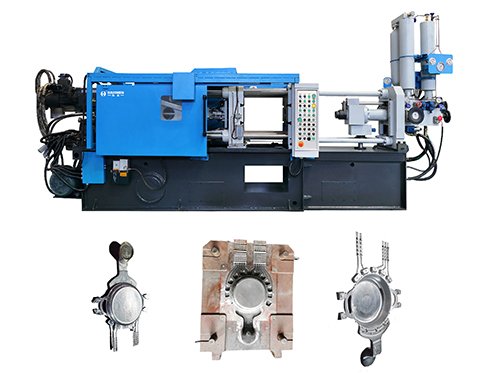

Haichen a manufacturer of Aluminum cookware Making die casting Machine.We can provide: Aluminum pots moulds, Aluminum pot making cold chamber die casting machines, related full range of automation auxiliary machinery.

Case: Efficient Die Casting Line for Deep Fry Pans

A well-known cookware brand uses a HAICHEN 650-ton cold chamber die casting machine to produce 28-cm aluminum deep fry pans. The pans require even wall thickness and a complex handle structure. The precise multi-stage injection control of the HAICHEN machine ensures smooth metal filling, perfectly forming the thin walls and complex features. The stable clamping force prevents flash. This production line achieves a stable output of thousands of pans per shift, with a product yield rate over 98%.

The production of Aluminum Pot requires the melting of raw aluminium alloys of the corresponding grades in a furnace, followed by the use of a cold chamber die casting machine to press the melted aluminium alloy into specially designed Aluminum Pot moulds, which are then cooled down and taken out by a Extractor.With our Aluminum Pot production line, we can automate the entire production process week after week.

Choosing aluminum cookware is a smart decision that balances excellent heat conductivity, light weight, durability, and the high cost-effectiveness of mass production. Realizing these benefits relies heavily on the advanced manufacturing process of high-pressure die casting.