Cast aluminum kitchenware and other common kitchenware materials,such as stainless steel, cast iron, copper, ceramics, etc.

Cast aluminum offers lightweight, fast, even heating at a lower cost, making it great for everyday cooking, but it’s less durable and can react with acidic foods if uncoated.

Unlike heavier, superior-heat-retention cast iron, super-durable but less heat-conductive stainless steel, or non-stick ceramic/Teflon coatings that can degrade.

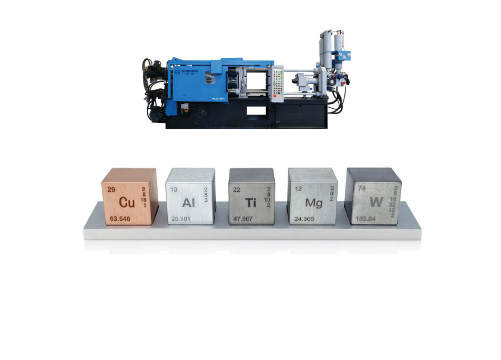

Die cast aluminum cookware

Die-cast aluminum cookware is made by injecting molten aluminum into molds under high pressure, creating durable, lightweight, warp-resistant pans that heat quickly and evenly.

This production method has the advantages of large-scale production and fast manufacturing. If you are interested, you can contact haichen.

Often featuring non-stick coatings for easy cooking and cleaning, making them a popular, affordable choice compared to heavier cast iron or stainless steel.

Its seamless design, often with handles molded directly onto the body, offers superior strength and ergonomic grip.

Die-cast aluminum material

Die-cast aluminum is a popular, lightweight material made by forcing molten aluminum alloys.

Such as A380, A360 into molds under high pressure, resulting in strong, complex parts with excellent corrosion resistance, high thermal/electrical conductivity, and good dimensional stability for thin walls.

Haichen‘s cold chamber high-pressure die-casting machines and high-pressure casting processes endow die-cast cookware with outstanding durability.

Comparative analysis with materials

- Stainless Steel

- Cast Iron

- Copper

- Ceramic

Stainless Steel

Thermal conductivity: The thermal conductivity of pure stainless steel is only 15-30 W/m·K.

Relying on aluminum or copper interlayers to improve performance.

Durability: corrosion resistance, scratch resistance, significantly longer life than cast aluminum.

Health and safety: non-reactive material, does not react with acidic food, no risk of metal precipitation.

Weight: slightly heavier than cast aluminum, but lighter than cast iron.

Price: High-end multi-layer stainless steel kitchenware is more expensive, but the long-term cost-effective.

Comparison conclusion: Stainless steel is more suitable for users who pursue durability and health and safety, but it needs to sacrifice some thermal conductivity efficiency.

Cast Iron

Thermal conductivity and insulation: thermal conductivity 48 W/m·K, lower than aluminum.

But strong heat storage capacity, suitable for slow cooking and frying.

Health: Cooking releases trace iron elements, which is beneficial to iron deficiency people, but it needs anti-rust maintenance.

Weight: significantly heavier than other materials, inconvenient to operate.

Price: The price of high-end cast iron pot is close to that of multi-layer stainless steel.

Comparison conclusion: Cast iron is suitable for users seeking thermal insulation and natural non-stick effect, but it needs to accept high maintenance costs.

Copper

Thermal conductivity: Thermal conductivity 401 W/m·K, optimal for all materials, suitable for precise temperature control (such as French sauce).

Health: The outer layer needs to be tinned or stainless steel to prevent copper precipitation, excessive intake may be harmful.

Price and maintenance: Expensive, need regular polishing to prevent oxidation.

Comparison conclusion: Copper is the top choice for professional kitchens.

But the cost and maintenance threshold is high.

Ceramic

Health and safety: Completely inert, no risk of metal precipitation, suitable for health-oriented users.

Thermal conductivity: Low thermal conductivity (about 1-2 W/m·K), which relies on uniform heating design to compensate.

Durability: fragile, not resistant to sudden cold and heat.

Comparative conclusion: Ceramic is suitable for low temperature cooking and health priority scenarios, but its practicality is limited.

Maintenance and maintenance methods

- Stainless steel

- Cast iron

- Nonstick coating

- Copper

- Aluminum

Stainless steel

Clean to avoid the use of steel balls, you can use neutral detergent.

Stubborn stains can be soaked in vinegar water.

Boil the new pot in 50% vinegar water for 2 hours before first use and repeat 6 times to reduce metal release, which will prevent discoloration.

Cast iron

After cleaning, apply vegetable oil and bake at 450℃ for 30 minutes to form a protective layer.

Daily maintenance should avoid soaking, dry and apply thin oil to prevent rust.

Nonstick coating

It should be noted that the metal shovel will destroy the layer and avoid empty burning.

Soft cloth and mild detergent for cleaning.

Copper

Periodically remove the oxide layer with lemon juice and salt or a special copper cleaner.

Aluminum

Hard anodized aluminum,machine washable.

Ordinary aluminum POTS should be washed by hand to avoid strong alkaline cleaners.