Common casting alloy types include aluminum, zinc, and magnesium, each offering unique properties for die casting applications.

Casting alloys are essential materials used in the die casting process to produce various metal parts.

The choice of alloy depends on the specific requirements of the part, such as strength, corrosion resistance, and thermal properties.

This article will explain the core characteristics, typical applications, and key grades of these alloys. It will analyze comprehensive factors for selection in real production.

Finally, it will introduce how HAICHEN die casting machines provide optimized solutions for different alloy properties.

Common casting alloy types

- Aluminum Alloys

- Zinc Alloys

- Magnesium Alloys

- Copper Alloys

Aluminum Alloys

Manufacturers prefer aluminum alloys for casting because they combine lightweight characteristics with high strength and excellent thermal properties. They are ideal for producing parts that require high strength – to – weight ratios, such as automotive components, aerospace parts, and consumer electronics.

Advantages

- Lightweight: Aluminum alloys have a low density, making them suitable for applications where weight is a critical factor.

- High Strength: They offer excellent strength and stiffness, making them suitable for structural applications.

- Corrosion Resistance: Aluminum alloys are resistant to corrosion, making them suitable for outdoor and marine applications.

Common Grades

- A356: A common aluminum alloy used for general – purpose casting applications.

- A380: Known for its high strength and good machinability.

- A360: Offers excellent corrosion resistance and good mechanical properties.

Zinc Alloys

Manufacturers value zinc alloys for their high strength, dimensional stability and superior surface finish. These alloys excel in producing precision components like electronic parts, toys and automotive fittings.

Advantages

- High Strength: Zinc alloys offer high strength and hardness, making them suitable for wear – resistant applications.

- Good Surface Finish: They can be easily polished and plated, resulting in a high – quality surface finish.

- Low Melting Point: Zinc alloys have a low melting point, making them easy to cast and process.

Common Grades

- Zamak 2: A common zinc alloy used for general – purpose casting applications.

- Zamak 3: Known for its high strength and good machinability.

- Zamak 5: Offers excellent corrosion resistance and good mechanical properties.

Magnesium Alloys

Magnesium alloys are the lightest of all casting alloys, making them ideal for applications where weight reduction is critical. They are commonly used in the automotive and aerospace industries for producing lightweight components.

Advantages

- Lightweight: Magnesium alloys have the lowest density of all casting alloys, making them suitable for weight – critical applications.

- High Strength: They offer good strength – to – weight ratios, making them suitable for structural applications.

- Good Thermal Properties: Magnesium alloys have good thermal conductivity and low thermal expansion, making them suitable for high – temperature applications.

Common Grades

- AZ91D: A common magnesium alloy used for general – purpose casting applications.

- AM60B: Known for its high strength and good machinability.

- AS41B: Offers excellent corrosion resistance and good mechanical properties.

Copper Alloys

Copper alloys, such as brass and bronze, are known for their excellent thermal and electrical properties, as well as their good corrosion resistance. They are commonly used for producing parts that require high thermal or electrical conductivity, such as heat exchangers, electrical components, and plumbing fixtures.

Advantages

- Excellent Thermal and Electrical Properties: Copper alloys have high thermal and electrical conductivity, making them suitable for applications where heat or electricity transfer is critical.

- Good Corrosion Resistance: They are resistant to corrosion, making them suitable for outdoor and marine applications.

- Aesthetic Appeal: Copper alloys have a pleasing appearance, making them suitable for decorative applications.

Common Grades

- C360: A common brass alloy used for general – purpose casting applications.

- C878: Known for its high strength and good machinability.

- C954: Offers excellent corrosion resistance and good mechanical properties.

Core Alloy Types and Their Characteristics

Common casting alloy types in die casting are categorized by their base metal, each offering unique performance advantages to meet diverse product needs.

- Aluminum Alloys: Lightweight and Strong General Choice

- Zinc Alloys: High Precision and Excellent Surface Finish

- Magnesium Alloys: The Ultimate Lightweight Material

- Copper Alloys: Superior Thermal and Electrical Conductivity

Aluminum Alloys: Lightweight and Strong General Choice

Aluminum alloy is one of the most widely used common casting alloy types. It has low density, good strength-to-weight ratio, thermal conductivity, and corrosion resistance. Typical grades like ADC12 (A383) offer good fluidity and high strength, suitable for complex parts like engine blocks. A380 provides a balance of casting performance and mechanical properties, used widely for various housings.

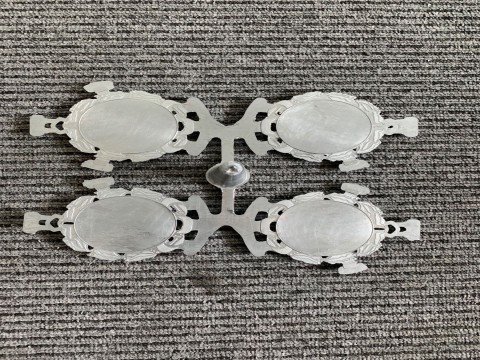

Zinc Alloys: High Precision and Excellent Surface Finish

Zinc alloys have excellent fluidity, allowing them to form thin walls and fine details with stable dimensions and smooth surfaces. Zamak 3 is the most common grade, used for decorative and hardware parts. Its low melting point suits hot chamber die casting for high efficiency.

Magnesium Alloys: The Ultimate Lightweight Material

Among common casting alloy types, magnesium alloys have the lowest density, high specific strength, and good damping capacity. AZ91D is the most common die-casting magnesium alloy, used in weight-sensitive parts like car steering wheels and laptop cases. Melting requires protective gas to prevent oxidation.

Copper Alloys: Superior Thermal and Electrical Conductivity

Mainly include brass and bronze. They offer excellent thermal/electrical conductivity, wear and corrosion resistance. Although more challenging and costly to cast, they are used for critical parts like valves, gears, and electrical connectors requiring these properties.

Key Factors in Alloy Selection

Choosing the most suitable from the common casting alloy types for a specific product requires systematic evaluation based on technical needs and cost-effectiveness.

- Product Mechanical and Physical Requirements

- Production Cost and Economic Analysis

- Production Efficiency and Process Compatibility

Product Mechanical and Physical Requirements

This is the primary basis for selection. Clarify needs for strength, hardness, toughness, weight, thermal/electrical conductivity, corrosion resistance, and appearance. For example, automotive structural parts often use high-strength aluminum alloys, while decorative parts may prioritize the plating quality of zinc alloys.

Production Cost and Economic Analysis

Costs include material price, melting energy, mold life, cycle time, and post-processing. For instance, magnesium has high material cost and requires protective gas, but its lightweight may add value. Zinc alloys have higher density but their excellent fluidity and low melt point reduce energy use and mold wear.

Production Efficiency and Process Compatibility

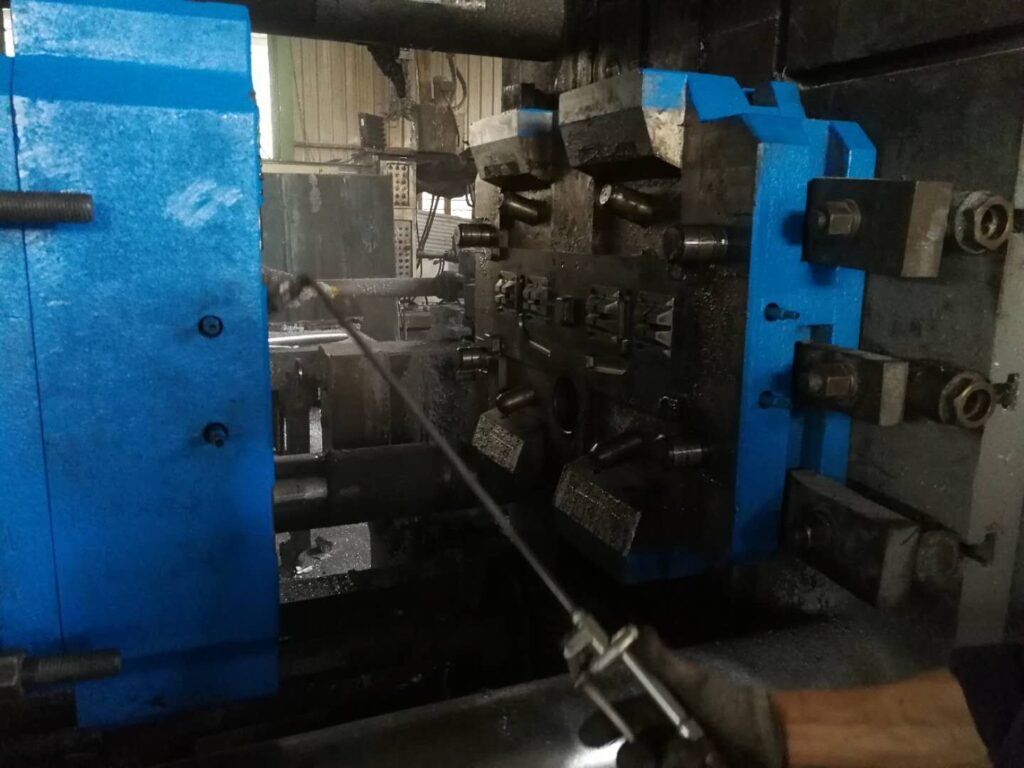

An alloy’s casting properties directly affect efficiency and equipment choice. Zinc and magnesium suit fast hot chamber die casting; aluminum and copper require cold chamber machines. The chosen alloy must be fully compatible with existing or planned die casting machines (like HAICHEN cold or hot chamber models), mold materials, and post-processing.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines designed to handle a wide range of casting alloys. Our machines are equipped with advanced features that ensure consistent performance and high – quality production. Whether you are producing aluminum, zinc, magnesium, or copper alloy parts, HAICHEN has the solutions to meet your needs.

Case: Efficient Forming of Precision Zinc Connectors

An electronics manufacturer needed high-volume production of miniature zinc alloy connectors with tight tolerances. Using a HAICHEN 90-ton hot chamber machine, its fast cycle time and stable injection ensured dimensional consistency. It minimized flash, reducing secondary processing costs and increasing production efficiency by about 25%.

Understanding the common types of casting alloys and their applications is essential for achieving high – quality and efficient die casting production. By choosing the right alloy for your specific application, you can ensure optimal performance and durability of the final product.