The best alloys for casting includes aluminium-based alloys, copper-based alloys, magnesium alloys and so on.

There is no single “best” alloy for all die casting. The optimal choice balances strength, weight, surface finish, cost, and production speed. Aluminum, zinc, and magnesium alloys each serve different purposes. Success comes from matching the material to the product’s function and production goals. With HAICHEN’s technical support, manufacturers can make informed decisions, avoiding trial and error. This leads to better products, smoother production, and stronger competitiveness in the market.

The choice of casting alloy depends on the specific application requirements, including mechanical properties, corrosion resistance, processing performance and cost. The following is a detailed analysis and recommendation of some of the best casting alloys:

The best alloys for casting: Aluminum-based alloys

A380 alloy

This is one of the most commonly used aluminum alloys.

And it highly regarded for its excellent comprehensive properties. Including light weight, high strength, high temperature resistance and good corrosion resistance.

It performs well in complex shapes and thin-walled parts. While maintaining good dimensional stability and thermal conductivity. Making it ideal for casting automotive, electronic equipment and industrial components.

A360 and A383 alloys

- These two alloys perform better in high temperature resistance and hot cracking resistance, and are suitable for parts that require high pressure and high temperature environments.

- A360 alloy excels in pressure sealing and corrosion resistance, while A383 alloy provides higher strength at high temperatures and reduces the risk of hot cracking.

Al-Si alloys

Such as AlSi7Mg0.3, AlSi8Cu3, etc. These alloys are widely used in the automotive industry and industrial castings. Due to their good mechanical properties, corrosion resistance and castability.

They can obtain better mechanical properties after heat treatment and are suitable for manufacturing wheels, structural castings and suspension components.

The best alloys for casting: Copper-based alloys

Cu-Sn-Zn-Pb alloy

This alloy performs well in sand casting, has good castability, mechanical properties and corrosion resistance, and is suitable for manufacturing precision parts such as valves, pumps and bearings.

Copper alloy AB1

This alloy is suitable for cost-effective sand casting, and has good welding performance and corrosion resistance, and is suitable for marine engineering and petrochemical industries.

The best alloys for casting: Magnesium alloys

AZ91 alloy

- This is one of the most widely useS alloy among magnesium alloys.

- And it widely uses in the automotive and aerospace fields. Due to its excellent casting properties, high strength and corrosion resistance.

- However, it is prone to creep at high temperatures. And it has poor corrosion resistance in some cases. But its performance can be improved by improving its composition.

AZ51 and ZA8 alloys

These alloys have higher mechanical strength and ductility, are suitable for hot press casting, and can produce complex parts with high structural strength and appearance.

The selection of the best casting alloy should be based on specific application requirements, such as strength, corrosion resistance, machinability and economy.

For example, aluminum-based alloys (such as A380 and A360) are suitable for most industrial applications, while magnesium alloys (such as AZ91) are suitable for areas that require light weight and high strength.

Copper alloys excel in corrosion resistance and thermal conductivity and are suitable for specific industrial uses. In addition, iron-based and titanium alloys also play an important role in specific fields.

How to choose the best alloy for casting?

Selecting the best material means matching alloy traits to your product’s specific demand.

- For High Strength and Light Weight

- For Excellent Surface Finish and Detail

- For Low Cost and High Production Speed

For High Strength and Light Weight

Choose aluminum or magnesium. For structural parts like car brackets, aluminum A380 is a top choice. For the lightest parts like laptop cases, consider magnesium AZ91D.

For Excellent Surface Finish and Detail

Zinc alloys are the best. They flow very well into fine mold details. Zinc parts, like decorative door handles, often need little finishing after casting.

For Low Cost and High Production Speed

For high-volume items, zinc offers fast cycle times in hot chamber machines. For larger parts where weight matters, aluminum ADC12 provides a good balance of performance and cost.

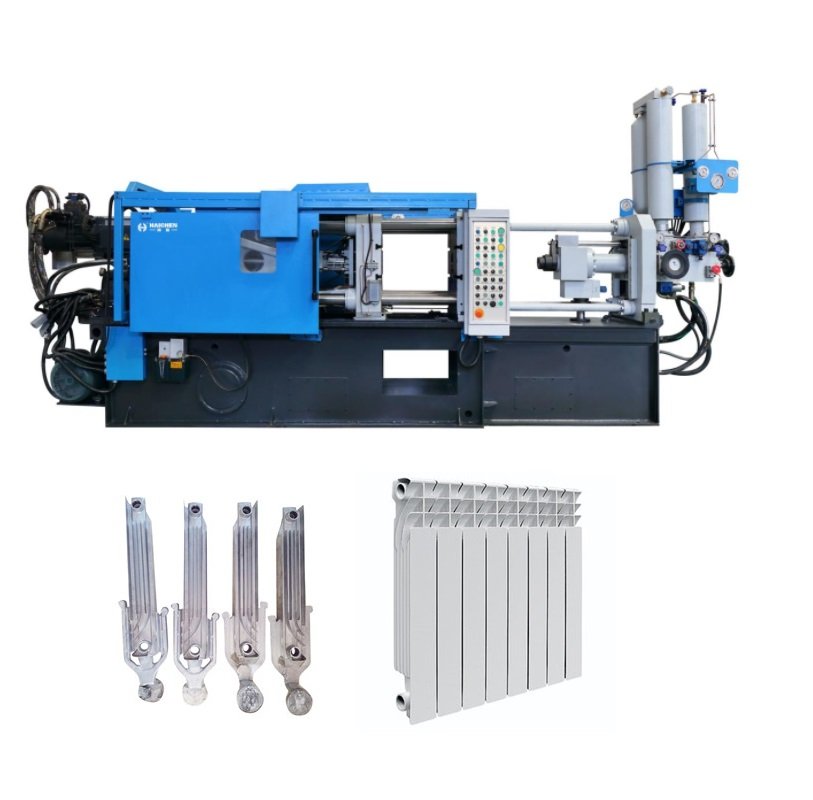

Haichen experience of best alloys for die casting

We can help clients choose the right alloy and machine for optimal results.

- Change alloys for aluminium Auto Part

- Optimize production for a metal electronics cover

Change alloys for aluminium Auto Part

One of Haichen clients made an engine mount from a standard aluminum grade. The part was strong but heavy, and the client wanted to reduce weight. HAICHEN engineers suggested switching to a high-strength aluminum alloy suitable for our cold chamber machines. This new alloy allowed for thinner walls without losing strength. The part weight dropped by 15%, and production remained stable on HAICHEN presses.

Optimize production for a metal electronics cover

For example, a customer used a generic aluminum alloy. They faced issues with surface finish and long cycle times. After analysis, HAICHEN recommended a different aluminum alloy with better fluidity for their specific part geometry. Paired with process tuning on our machine, this change improved surface quality and reduced cycle time by 10%, boosting daily output.

As a professional die casting machine manufacturer, HAICHEN provides more than equipment. Our deep process knowledge helps you select the best alloys for casting your specific products. We understand how material choice interacts with machine settings. This allows us to offer complete solutions that ensure quality, efficiency, and cost-effectiveness for manufacturers in Turkey and beyond.

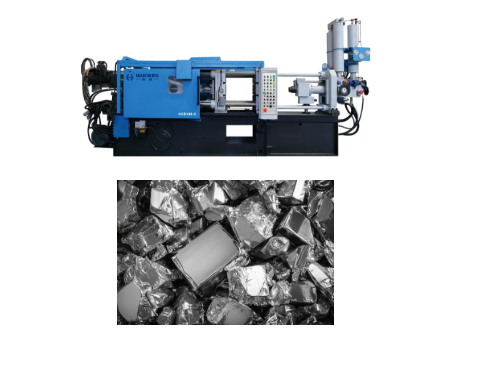

Haichen die casting machine

At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.