Hydraulic oil for die casting machines needs to have wear resistance, oxidation resistance, rust resistance, and appropriate viscosity.

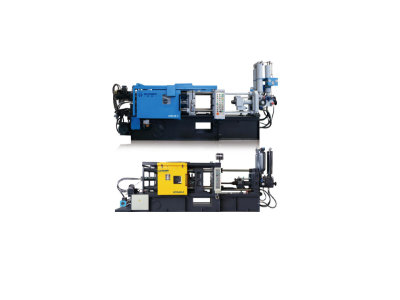

There are differences in the suitability of anti-wear hydraulic fluids, such as ISO VG68, in cold and hot chamber die casting machines, mainly depending on the temperature, pressure, and working environment of the hydraulic system.

Hot chamber die casting machines are more suitable for using high-viscosity hydraulic fluids (such as ISO VG68), while cold chamber die casting machines may require hydraulic fluids with lower viscosity or better low-temperature adaptability.

When selecting hydraulic fluid, comprehensive consideration should be given to equipment type, working conditions and hydraulic system requirements to ensure efficient operation and extended service life of the equipment.

Core requirements of hydraulic oil for die casting machines

- Wear resistance

- Oxidation resistance and thermal stability

- Temperature adaptability

- System compatibility

- Anti-rust and anti-pollution

- Cleanliness and filterability

- Resistance to emulsification and water separation

- Environmental protection and compatibility

Wear resistance

The hydraulic system of the die-casting machine needs to withstand high pressure (120-250 bar).

And frequent impact loads, so high pressure anti-wear hydraulic oil (HM grade) must be selected.

This type of oil can form a protective film on the metal surface to reduce friction and wear.

Especially for precision components such as plunger pumps and servo valves.

Oxidation resistance and thermal stability

The high temperature environment (the working temperature of the die-casting machine is often above 60 ° C)

Is easy to accelerate the oxidation of the oil, resulting in the formation of sludge and acidic substances.

High-quality hydraulic oil needs to contain efficient antioxidants.

To ensure stable performance at high temperatures and extend the oil change cycle to 1.5-2 years.

Temperature adaptability

In winter, use ISO VG46 for its excellent low-temperature fluidity.

And switch to ISO VG68 in summer to maintain oil film strength under high-temperature conditions.

When operating temperatures consistently exceed 60°C, consider selecting high-viscosity oils like VG100.

System compatibility

Too low viscosity leads to leakage and pump wear, too high increases energy consumption and reduces response speed.

Anti-rust and anti-pollution

Metal dust and water in the die casting environment are easy to mix into the oil.

So it is necessary to choose an oil containing anti-rust agent and strong anti-emulsification.

And regularly monitor the cleanliness (NAS grade is recommended to be ≤9).

Cleanliness and filterability

Hydraulic fluids must have low impurity content and high cleanliness, according to NAS 1638 or ISO 4406 standards.

For example, Saint-Paulo high clean hydraulic fluids are rated NAS Level 5 to meet the needs of precision hydraulic systems.

Resistance to emulsification and water separation

The environment of the die-casting workshop may be mixed with water, and the hydraulic oil needs to quickly separate the water (demulsification time is less than 30 minutes).

To prevent the emulsification resulting in decreased lubrication and acid corrosion.

Environmental protection and compatibility

In some scenarios, an environmentally friendly hydraulic fluid (such as the Ecoterra® zinc-free formula) is used to avoid corrosion of silver.

And copper components and is compatible with sealing materials (such as nitrile butadiene rubber, fluoroprene rubber).

Recommended hydraulic oil brand and model

- Special anti-wear hydraulic oil

- High cleanliness hydraulic fluid

- Environmentally friendly hydraulic oil

- International brand

Special anti-wear hydraulic oil

LK Series: Specially designed for die-casting machines, wear resistance up to FZG grade 12, excellent foam resistance and air release, reduce sludge formation.

Kunlun L-HM Series: Zinc-containing or ash-free formulations according to DIN 51524 and Denison HF-0 for medium and high pressure systems.

Ebon Ash free HR46/68: no zinc, avoid oxidized silver parts, strong water separation, suitable for humid environment.

High cleanliness hydraulic fluid

NAS Grade 5 Hydraulic oil: High pressure hydrogenation base oil, multi-stage filtration process, suitable for servo control systems and precision die casting machines.

Environmentally friendly hydraulic oil

Ecoterra® Zinc-free hydraulic fluids: Biodegradable > 90% according to ISO 11158 HM for environmentally demanding applications.

International brand

Mobil DTE 10 Extraordinary series: high anti-wear, anti-oxidation, oil change period extended by more than 30%.

Shell Lux S2 M: Excellent resistance to emulsification, suitable for high humidity environments.

Use and maintenance points

- Oil change cycle Management

- Pollution control

- Temperature monitoring

Oil change cycle Management

The first 500 hours of the new machine oil change, subsequent every 2000 hours or annually (depending on the oil test results).

When changing oil, the system should be thoroughly washed to avoid mixing old and new oil (residual old oil ≤5%).

Pollution control

Install a high precision filter (β≥200) and clean the tank and cooler regularly to prevent metal debris and moisture intrusion.

Oil water treatment: stop drainage immediately, detect acid value changes, replace and clean the system if necessary.

Temperature monitoring

The optimal oil temperature is controlled at 20-45 ° C, and when the temperature exceeds, check the efficiency of the cooler or switch to high viscosity oil.

Environmental trends and technological innovation

- Biodegradable hydraulic oil

- Low toxicity and renewable oil

- Intelligent monitoring

Biodegradable hydraulic oil

Such as polyol ester products, 28-day biodegradation rate > 60%, suitable for ecologically sensitive areas.

Low toxicity and renewable oil

The EU REACH regulation promotes the development of zinc-free (Zn < 0.03%).

Low PAH (polycyclic aromatic hydrocarbons) formulations to reduce environmental toxicity.

Intelligent monitoring

Predictive maintenance with real-time monitoring of viscosity, moisture and granularity by oil sensors (e.g. Mobil Signum Analytical Services).