Long life plunger rod requires a combination of materials science, precision engineering, and maintenance strategies.

Highly wear-resistant matrix materials (e.g., tungsten carbide) combined with surface strengthening technologies (e.g., laser cladding) are at the core.

While cooling and lubrication system optimization and preventive maintenance further ensure their reliability.

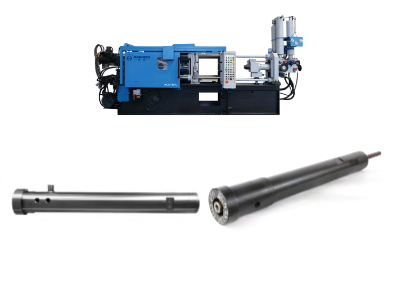

Definition and function of Long life plunger rod

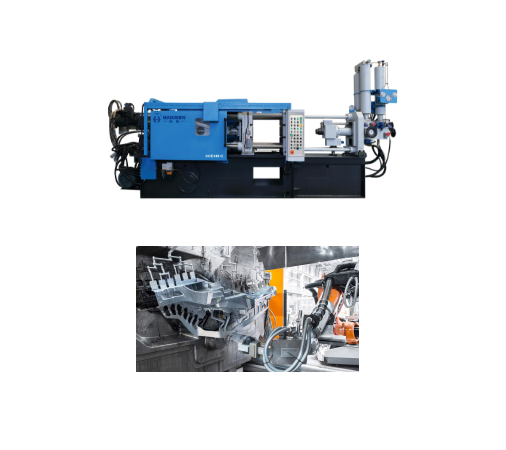

In the die-casting process, the plunger rod also known as the injection plunger or injection punch is one of the core components of the injection mechanism.

Which is mainly used to inject molten metal into the mold cavity at high speed and high pressure.

Power Transmission

Driven by a hydraulic or mechanical system, the power is converted into a linear motion that pushes the molten metal into the mold.

Pressure control

By precisely controlling the injection speed and pressure, the molten metal is ensured to evenly fill the mold cavity, avoiding air entrapment and shrinkage defects.

Sealing and guidance

Cooperate with the injection cylinder to form a confined space to prevent the leakage of molten metal.

And at the same time maintain the stability of the movement through the guiding device.

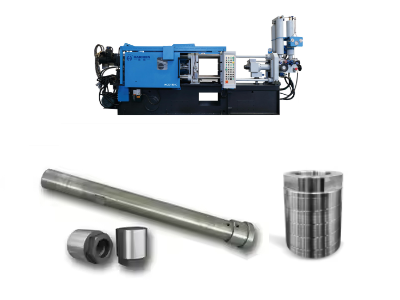

Material selection and surface treatment technology

Substrate material optimization

High-toughness alloy steel: Pre-hardened QT steel (28-32 HRC) and 4150 steel are the mainstream matrix materials due to their combination of strength and thermal fatigue resistance.

Tungsten carbide (Carbide): The hardness of the tungsten carbide plunger body prepared by powder metallurgy is more than HRA 90.

And the wear resistance is 5-8 times that of traditional steel, especially suitable for highly abrasive media.

Silicon nitride (Si₃N₄): Experiments show that its wear is only 0.03-0.04 mm for 1000 hours.

And its service life is more than 3000 hours, but the cost is high.

Surface strengthening technology

Boron infiltration treatment

The surface hardness of No. 45 medium carbon steel is HV 1500 after boronization, and the service life is increased by 6-10 times.

Ceramic coatings

Plasma spray zirconia (ZrO₂) or chromium carbide (CrC) coatings can reduce the coefficient of friction by 30% and extend the life by up to 2 times.

Laser cladding

Cladding stainless steel coating (thickness 25-500 μm) on a 35CrMo substrate increases corrosion resistance by 3 times and reduces wear rate by 40%.

Geometric accuracy and fit design

- Gap control

- Cooling System

Gap control

The gap between the plunger tip and the sleeve should be ≤ 0.004 inches (0.1 mm) to prevent reverse osmosis of the molten aluminum.

Cooling System

The Advance™ plunger rod uses 3/8″ brass cooling tubing to ensure that the coolant reaches the tip and evenly dissipates heat to prevent thermal cracking.

Experiments have shown that optimized cooling can reduce thermal stress by 25%.

Lubrication system integration

- Built-in lubrication channel

- Specialty lubricants

Built-in lubrication channel

Precision-engineered lubrication lines (e.g., TLS series) reduce frictional power consumption by up to 15% while avoiding lubricant contamination of the molten metal.

Specialty lubricants

Lubricants containing PTFE particles, for example HOUGHTON PLUNGER TIP LUBE 7176, form a protective film at high temperatures, extending maintenance intervals by up to 30%.

Long life plunger rod Installation and maintenance specifications

- Installation accuracy control

- Preventive maintenance measures

Installation accuracy control

The concentricity error between the punch and the injection chamber and the hammer handle should be ≤ 0.05mm.

And the laser alignment instrument should be used to calibrate it during installation to avoid jamming or breaking caused by eccentricity.

After the ceramic punch is installed, it needs to be preheated to the working temperature.

Such as aluminum alloy die-casting needs to be preheated 7-10 times to eliminate the cold assembly stress.

Preventive maintenance measures

Regular inspection

Check the scratch depth on the punch surface every 500 molds (≤0.1mm is the safe value).

And use ultrasonic flaw detection to check for internal cracks.

Seal replacement

Replace the O-ring or lip seal every 4 months, and use special tools to avoid scratching the rod body when disassembling.

Cleaning management

Use methanol or isopropanol to clean the surface salt crystal residue during shutdown to prevent corrosive substances.