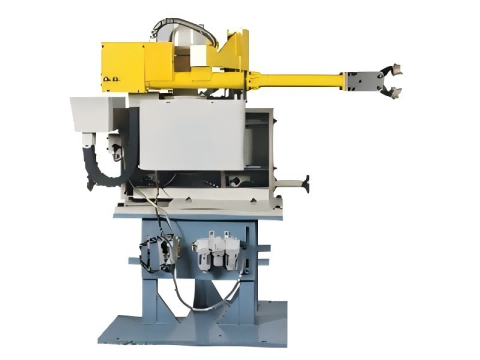

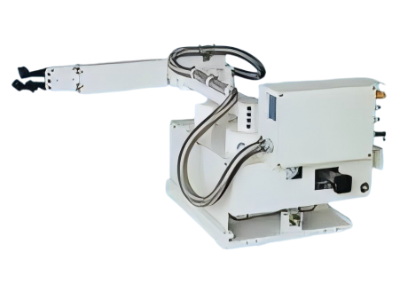

Automatic Extractor Used for Die Casting Molds efficiently removes castings with precision, reducing cycle time and manual handling risks.

In the die casting industry, the efficiency and precision of mold extraction are critical factors that influence production quality and cycle time. An automatic extractor is a specialized tool designed to facilitate the removal of cast parts from the mold, ensuring smooth and consistent production.

This article will explore the functions, benefits, and applications of automatic extractors in die casting molds, highlighting their importance in modern manufacturing processes.

Functions of Automatic Extractors

1. Efficient Part Removal

The primary function of an automatic extractor is to remove the cast part from the mold cavity efficiently. Mechanical systems, often combined with pneumatic or hydraulic components, apply controlled force to safely release parts from molds.

2. Consistent Quality

Automatic extractors remove parts from molds with controlled precision, maintaining consistent casting quality. They reduce the risk of defects such as scratches or deformations that can occur during manual extraction.

3. Increased Production Efficiency

Automatic extractors significantly reduce the time required for part removal, thereby increasing overall production efficiency. They operate quickly and reliably, allowing for shorter cycle times and higher throughput.

Benefits of Using Automatic Extractors

1. Reduced Labor Costs

The use of automatic extractors minimizes the need for manual intervention in the part removal process, reducing labor costs and the potential for human error. This automation leads to more consistent and reliable production.

2. Enhanced Safety

Automatic extractors operate in a controlled environment, reducing the risk of accidents associated with manual part removal. They ensure that operators are not exposed to high temperatures or hazardous conditions, enhancing overall workplace safety.

3. Improved Mold Life

By applying consistent and controlled force during part removal, automatic extractors help prevent wear and tear on the mold. This extends the life of the mold, reducing maintenance costs and downtime.

Applications in Die Casting

1. Automotive Industry

The automotive industry relies on automatic extractors to achieve the precision and efficiency required for manufacturing complex engine parts and body panels.

2. Aerospace Industry

The aerospace industry also relies on automatic extractors for the production of high-precision components. These extractors ensure that parts meet stringent quality standards, contributing to the reliability and safety of aerospace products.

3. Consumer Electronics

For consumer electronics, automatic extractors help in the production of small and intricate parts. These systems produce precision housings and connectors with defect-free consistency.

HAICHEN: Your Partner in Die Casting Solutions

At HAICHEN, we specialize in manufacturing advanced die casting machines designed to meet the highest standards of precision and reliability. Our machines are equipped with efficient automatic extractors to ensure smooth and consistent part removal from the mold. Whether you are producing automotive parts, aerospace components, or consumer electronics, HAICHEN offers the tools and expertise to help you achieve your production goals.

Why Choose HAICHEN?

- Advanced Technology: Our die casting machines are equipped with state-of-the-art control systems and precision components to ensure high-quality production.

- Custom Solutions: We offer tailored machine configurations to meet specific production needs, including mold size, material type, and production volume.

- Quality and Reliability: HAICHEN machines are built to the highest standards of quality and reliability, ensuring consistent performance and minimal downtime.

- Comprehensive Support: Our commitment to customer satisfaction includes comprehensive after-sales support, technical assistance, and maintenance services.

Automatic extractors play a crucial role in the die casting process by ensuring efficient part removal, maintaining consistent quality, and increasing production efficiency. Automatic Extractor Used for Die Casting Molds achieves these benefits through precision robotics and synchronized operation with casting cycles.