Technical Parameter of Sprayers in Die Casting includes spraying method and automation, spray coating materials and processes, etc.

Automated spraying reduces labor costs, improves production efficiency, and reduces casting defect rates.

The spraying equipment can adapt to the requirements of different mold sizes and complexities, ensuring high-quality spraying effects.

Technical Parameter of Sprayers in Die Casting.The sprayer is a key part of a die casting machine. It applies release agent to cool and lubricate the mold. This article explains the main technical points of sprayers. We will look at spray pressure, flow rate, and pattern control. We will also share how HAICHEN uses these parameters in real cases.We will analyze the technical parameter of sprayers in die casting mainly from below 6 aspects:

- Main tasks of spraying equipment

- Spraying method and automation

- Spray coating materials and processes

- Structure and control of spraying equipment

- Environmental protection and sustainability

- Application scenarios of sprayer equipment

Key Technical Parameters for Sprayers

These settings control how the sprayer works.

- Spray Pressure and Flow Rate

- Nozzle Type and Spray Pattern

- Timing and Cycle Control

Spray Pressure and Flow Rate

Spray pressure pushes the release agent out of the nozzle. Higher pressure makes a finer mist. Flow rate decides how much agent is used per cycle. The right pressure and flow give even coverage without waste.

Nozzle Type and Spray Pattern

Different nozzles create different spray patterns. Flat fan nozzles cover wide areas. Cone nozzles target deep holes. The choice depends on your mold shape. The pattern must reach all critical mold surfaces.

Timing and Cycle Control

The spray time must sync with the machine cycle. It should happen after part ejection and before the next shot. Precise timing ensures good lubrication and cooling for every cycle.

Main tasks of spraying equipment

The main tasks of the spraying equipment include spraying the separating agent, lubricating the mold half, removing impurities, and cooling the mold. Spraying should be uniform and completed quickly to reduce production costs and ensure casting quality.

Spraying Mold Release Agent

Provides a uniform release agent across the mold surface, preventing castings from sticking and extending mold life.

Lubricating the Movable Mold Cavity

Lubricates the movable mold half to reduce friction, minimize impact, and ensure smooth mold closing.

Removing Impurities

Flushes away metal splatter, scale, and other impurities from the mold cavity to ensure casting surface quality.

Mold Cooling

Spray removes heat, helping the mold cool quickly and reducing thermal fatigue stress.

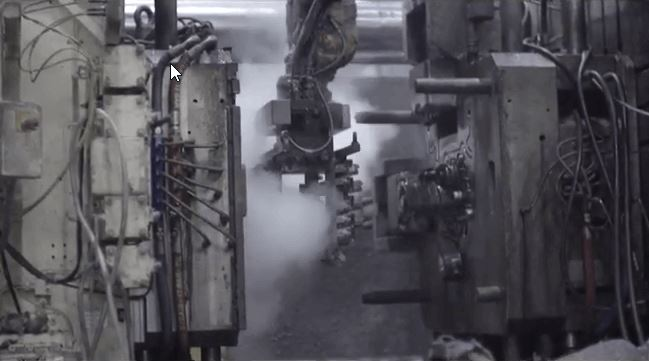

Spraying method and automation

Spraying equipment is usually operated through robotic arms or specialized nozzles, which can achieve automated spraying, reduce manual intervention, and improve efficiency.

The automatic spraying system can be adjusted according to the type of mold and production requirements, for example, by flexibly configuring the number and position of nozzles to optimize the spraying effect.

Air‑atomized

- Function: Uses high-pressure air to atomize lubricants or coolants into fine droplets, forming a uniform film.

- Typical Applications: Coating mold surfaces for anti-sticking and reducing injection resistance.

Liquid‑spray

- Function: Directly sprays oil-based or water-based lubricants through a multi-hole nozzle, often in conjunction with compressed air or air pressure regulation.

- Application: High-viscosity lubricants, rust prevention for metal surfaces.

Air‑blow

- Function: Air only, no liquid, is used to clean mold surfaces or remove excess lubricant.

- Application: Cleaning and removing moisture after mold opening.

Mist‑cooling

- Function: Low-temperature water mist or specialized coolant atomization assists internal cooling.

- Application: Enhanced cooling for aluminum alloy high-pressure casting.

Mechanical linkage structure

- The nozzle is mounted on a linkage mechanism and moves up and down in sync with the mold opening and closing.

- Motion sequence: First, blow air to clean → Apply lubricant → Blow air again to remove excess liquid → Return to the initial position when completed.

Sensors and Safety Protection

- Pressure sensors monitor air supply pressure in real time to prevent nozzle damage caused by overpressure.

- Position sensors confirm that the nozzle is in position before initiating spraying, preventing accidental spraying.

- Level/flow meters monitor lubricant usage, contributing to energy savings and environmental protection.

Spray coating materials

The spraying material is usually a separating agent (such as Chem Trend), which prevents the molten metal from adhering to the inner wall of the mold.

Water-Based Release Agent

- Application

Prevents molten metal from adhering to the mold - Key Performance Requirements

High-Temperature Resistance (≥300°C), Low Residue, Easy Cleaning

Oil-Based Lubricant/Rust Inhibitor

- Application

Reduced Friction, Protected Mold Surface - Key Performance Requirements

High-Temperature Oxidative Stability, Low Volatility

Epoxy/Polyurethane Anti-Corrosion Coating

- Application

Improved Mold Life, Anti-Corrosion - Key Performance Requirements

Heat Resistance (200-250°C), Wear Resistance

Ceramic/Metal Powder Coating

- Application

Improved Wear Resistance, Thermal Barrier - Key Performance Requirements

High Melting Point, Thermal Expansion Matching

Spray coating processes

During the spraying process, compressed air is used to clean the surface of the mold and remove excess lubricant.

Mold Pretreatment

- Cleaning/Degreasing: Use a solvent or alkaline cleaner.

- Preheating: Maintain a mold temperature of 150-220°C to ensure uniform coating drying.

Spray Parameter Settings

- Nozzle Selection: Depends on the liquid viscosity and spray pattern; a 1.0-1.6mm nozzle is commonly used.

- Air Pressure/Voltage: 21.75-29 psi for pneumatic spray guns; 10-30 kV for electromagnetic spray guns.

- Spray Distance: 250-300 mm (pneumatic) or 350 mm (gravity-fed)

- Spray Angle: 30-70°; fan or cone depending on mold geometry.

- Spray Time/Coverage: Based on the desired dry film thickness (DFT) and material consumption rate, a Taguchi design of experiments (DOE) is often used to optimize spray time, angle, and air pressure.

Actual Spraying

- Synchronized Spraying: Internal spray nozzles are synchronized with the machine tool to reduce metal spatter and improve yield.

- Multi-Coat Application: For thicker coats, apply in layers, drying at low temperature (80-120°C) between each coat.

Post-Processing

- Curing/Drying: Air dry or oven cure (150-200°C, 30-60 minutes) to ensure complete crosslinking.

- Inspection: Visual inspection, thickness gauge measurement (target thickness 10-30µm), and spot re-spraying as necessary.

Structure and control of spraying equipment

Spraying equipment usually consists of mechanical parts, electrical parts, and pneumatic parts. The mechanical part includes nozzles, moving mechanisms, etc; The circuit part is responsible for signal control; The air path is sprayed using compressed air.

Spraying equipment plays a key role in the die-casting process, and its technical parameters and functions directly affect production efficiency and casting quality.

PLC/Embedded Closed-Loop Control

- Real-time data is collected via pressure, flow, temperature, and position sensors.

- The controller generates PWM or valve opening commands based on the preset spray profile (time-pressure-flow), achieving precise spray volume and atomization.

Human-Machine Interface (HMI)

The operator can set the spray time, nozzle travel, and spray pattern (single shot, sweep, or pattern) on the touchscreen.

Application scenarios of sprayer equipment

Spraying equipment is widely used in various types of die-casting machines, including large and small molds. For example, when producing large automotive parts, the spraying equipment needs to be able to handle larger mold sizes and higher pressures.

HAICHEN’s Application of Sprayer Technology

HAICHEN integrates advanced sprayer systems to solve customer problems.

- Solving Release Issues for an Auto Part Producer

- Achieving Consistent Quality for a Consumer Goods Maker

Solving Release Issues for an Auto Part Producer

A customer making aluminum engine brackets had part sticking problems. HAICHEN engineers adjusted the spray pressure and changed the nozzle type. We increased pressure for better penetration into deep slots. After the change, parts released cleanly every time. Defect rates dropped by over 15%.

Achieving Consistent Quality for a Consumer Goods Maker

A maker of appliance housings faced uneven surface finish. HAICHEN helped optimize the spray timing and pattern. We set a longer spray time for large core surfaces. This ensured even cooling and lubrication. The result was a uniform, high-quality surface on every part.

HAICHEN Providing Integrated Die Casting Solutions

As a die casting machine manufacturer, HAICHEN designs sprayer systems as a core part of the machine. Our sprayers are built for precision and durability. They work seamlessly with our machines to ensure stable, efficient production. We provide not just equipment, but the technical know-how to optimize every parameter for our clients’ specific needs.

Understanding sprayer technical parameters is vital for efficient die casting. Key settings like pressure, flow, pattern, and timing directly impact part quality, mold life, and operating cost. Through practical cases, HAICHEN shows how precise adjustment of these parameters solves production challenges. Choosing a machine with a well-designed sprayer system, like those from HAICHEN, is a strategic step towards reliable and cost-effective manufacturing.

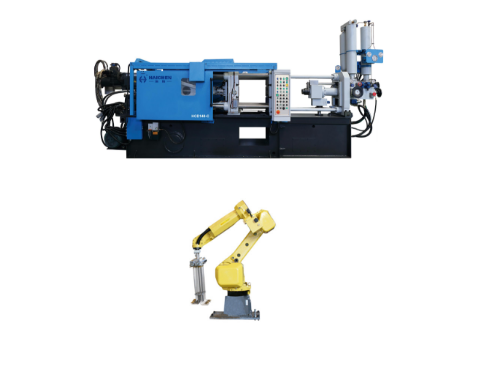

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.