Conveyor Type Comparison in die casting includes innovation in conveyor belt design, conveyor belt material selection, etc.

The type of conveyor belt used in die casting needs to take into account its functional requirements, design innovation, material selection, synergy with other equipment, and maintenance costs.

The development of modern conveyor belt technology (such as hybrid electric drive systems) provides new possibilities for improving die casting efficiency and reducing costs. But it also requires targeted design and optimization according to specific application scenarios.

- The role of conveyor belts in die casting

- Innovation in conveyor belt design

- Selection of conveyor belt materials

- Maintenance and cost of conveyor belts

- Synergy between conveyor belts and other equipment

The role of conveyor belts in die casting

- Continuous Conveying of Workpieces and Molds

- Coordinate of Cooling and Solidification Processes

- Process Integration and Automation

- High-Temperature Handling

- Reduce Energy Consumption and Equipment Wear

Conveyor belts are mainly used in die casting production to efficiently transfer molds, castings or related components between different processes.

For example, in large die casting machines, conveyor belts can be used in combination with hydraulic or hybrid electric drive systems to improve the smoothness of mold opening and closing, reduce wear and reduce energy consumption.

Continuous Conveying of Workpieces and Molds

Quickly and reliably transfer hot molds, cast blanks, or semi-finished products between different process steps, avoiding fatigue and injuries caused by manual handling.

Coordinate of Cooling and Solidification Processes

A belt cooling system (such as a water bath or cooling belt) provides immediate temperature control after ejection. Ensuring rapid and uniform cooling of the metal, improving dimensional accuracy and surface quality.

Process Integration and Automation

Conveyor belts connect die-casting machines, deburring, cleaning, inspection, and packaging into a single production line. Enable fully automated production and significantly increasing productivity.

High-Temperature Handling

Specialized high-temperature, heat-resistant conveyor belts (resistant to temperatures exceeding 1000°C) are used for direct handling of molten metal or high-temperature castings, preventing heat loss and equipment damage.

Reduce Energy Consumption and Equipment Wear

Using hydraulic or hybrid electric drive conveyor systems, the speed of mold opening and closing can be smoothly controlled, reducing impact and mechanical wear, and lowering overall energy consumption.

Innovation in conveyor belt design

- Hybrid Electric Drive and Energy-Saving System

- Modular Scalable Structure

- High-Temperature Materials

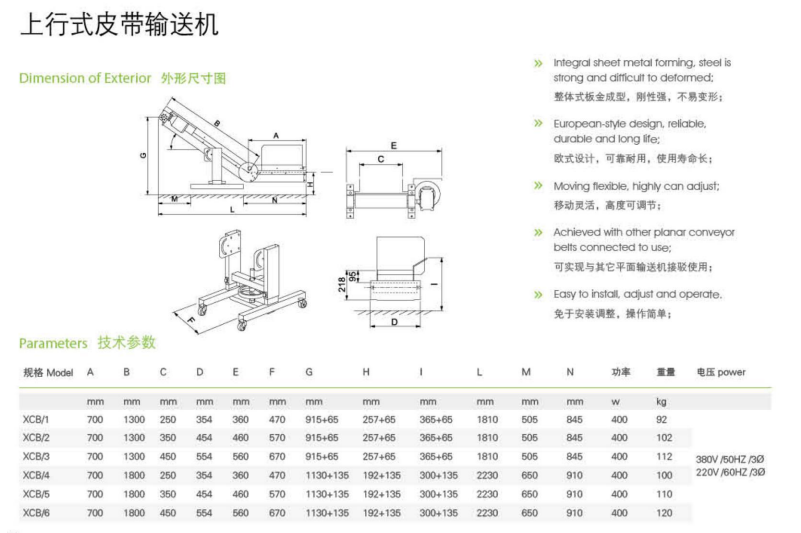

- Inclined/High-Angle Conveying Technology

In modern die casting machine design, the structure and function of conveyor belts are being continuously optimized. For example, conveyor belts with hybrid electric drive systems can significantly improve energy efficiency and reduce the need for additional components.

This design not only shortens the production cycle, but also reduces the weight of the equipment (about 15%-20%), thereby improving overall production efficiency.

Hybrid Electric Drive and Energy-Saving System

- Combining hydraulic or conventional motors with hybrid electric drive enables smoother mold opening and closing, reduces wear, and lowers energy consumption.

- Some systems also enable regenerative braking, feeding braking energy back into the power grid.

Modular Scalable Structure

- A modular frame and standardized connectors facilitate quick replacement of conveyor sections and addition or removal of workstations.

- The design includes reserved intelligent expansion interfaces (communication bus, sensor slots), leaving room for future digital upgrades.

High-Temperature Materials

- Metal chain plates/stainless steel mesh belts: Suitable for transporting hot castings above 300°C.

- High-temperature rubbers or polymers such as PTFE, EPDM, silicone, and polyimide: resistant to temperatures between 200°C and 260°C, and resist sticking and staining.

- Composite fiber (glass fiber + Kevlar) and metal mesh: Offers a balance of strength and lightweight.

Inclined/High-Angle Conveying Technology

- High sidewalls and reinforced anti-slip texture prevent materials from sliding even at inclinations of 30°-45° or even steeper.

- Compact layout significantly reduces workshop floor space.

Selection of conveyor belt materials

- Polyurethane (PU) conveyor belt

- Polyvinyl chloride (PVC) conveyor belt

- Silicone Conveyor Belt

- Metal Chain (Steel Chain)

The material selection of conveyor belts has an important impact on their performance. For example, materials such as aluminum, magnesium, zinc and zinc alloys are widely used in die casting because they have good mechanical properties and corrosion resistance.

The choice of these materials can indirectly affect the design and service life of conveyor belts, especially in application scenarios that require high strength and durability.

Polyurethane (PU) conveyor belt

- Fiber cord + PU cover

- Highly wear-resistant, oil-resistant, flexible, and suitable for medium loads

- Suitable for most die-casting cooling and handling processes

Polyvinyl chloride (PVC) conveyor belt

- Fiber cord + PVC cover

- Low cost, flame retardant, weather-resistant, and flexible. Suitable for processes with low temperatures and less stringent chemical corrosion requirements

Silicone Conveyor Belt

- Silicone layer + fabric

- Excellent high-temperature resistance (approximately 200°C)

- Suitable for hot gates and immediate handling after heat treatment

Metal Chain (Steel Chain)

- Metal Chain + Sheath

- Highest load capacity, high temperature resistance, and wear resistance

- Only used in extremely heavy loads or high temperatures, and most expensive

Maintenance and cost of conveyor belts

- Overall system maintenance costs

- Routine maintenance tasks

The maintenance cost and service life of conveyor belts are also important factors to consider when choosing the type of conveyor belt.

For example, traditional conveyor belts may require frequent replacement of parts, while conveyor belts with new hybrid electric drive systems may have longer service life and lower maintenance costs.

Overall system maintenance costs

75% of the total cost comes from the conveyor belt itself (including the belt, drive, and tensioning device).

Routine maintenance tasks

- Remove belt surface debris (scraper, brush, spray wash)

- Tighten tension bolts or adjust counterweights

- Inspect joints, belt cracks, and roller wear

- Replace worn drive sprockets and reducer oil

- Spare parts inventory (motor, reducer, belt segments)

HAICHEN Integrated Conveyor Solutions

HAICHEN provides conveyors that fit with our machines for smooth workflow.

- Belt Conveyor for Aluminum Housings

- Chain Conveyor for Heavy Transmission Parts

Belt Conveyor for Aluminum Housings

A client makes small aluminum electronic housings. Parts are light and cool quickly. HAICHEN suggested a narrow belt conveyor. It moves parts gently to the trim station. The system is low-cost and easy to maintain, fitting their high-mix production.

Chain Conveyor for Heavy Transmission Parts

Another client casts large transmission cases. Parts are heavy and stay hot longer. We installed a heavy-duty chain conveyor with cooling fins. It carries the hot parts steadily and helps them cool. This robust solution handles tough conditions daily.

As a die casting machine manufactuer, HAICHEN sees the whole production line. We know conveyors are a key link between machines. Our advantage is offering matched machines and conveyors. We design for smooth flow, less handling, and higher overall efficiency. With HAICHEN, you get a coordinated system, not just separate machines.

Synergy between conveyor belts and other equipment

Conveyor belts usually need to work in conjunction with other equipment (such as molds, injection machines, etc.).

For example, the technical specifications of the DC series die-casting machine show that its conveyor belts need to be able to adapt to molds and castings of different sizes and weights.

In addition, the design of the conveyor belt also needs to consider the opening and closing mechanism of the mold to ensure the quality and production efficiency of the casting.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.