Automated die casting with robot is a technology that uses industrial robots to optimize and improve traditional die casting processes.

The automated die casting and robots is an important technology in modern manufacturing, and its main purpose is to improve production efficiency, reduce costs and improve product quality.

The combination of automated die casting and robotics not only significantly improves production efficiency and product quality, but also reduces production costs and labor requirements. This technology has a wide range of applications, covering a variety of fields from automotive parts to industrial equipment. With the continuous advancement of technology, automated die casting and robotics will play a greater role in the future manufacturing industry.

What is Automated die casting with robot?

Automated die casting combined with robots is a technology that uses industrial robots to optimize and improve traditional die casting processes. This technology realizes the automation of the die casting process by introducing a robotic system, thereby improving production efficiency, precision and safety.

Basic concept of automated die casting

Automated die casting refers to the combination of robotic technology with die casting equipment to achieve full process automation from metal injection to finished product processing.

For example, robots can be used for steps such as grasping, positioning, cooling, trimming and storing die castings.This integrated production method not only reduces the need for manual operation, but also significantly improves production efficiency and product quality.

Advantages of automated die casting with robot

- Improve production efficiency

- Reduce labor costs and improve the working environment

- Improve product quality and consistency

- Enhance flexibility and adaptability

- Enhance safety

- Reduce mold damage

Automated die casting has brought significant benefits by introducing robotic technology:

Improve production efficiency

The automated die-casting system uses robots to replace traditional manipulators to complete operations such as picking and blowing. And combines the multi-machine control mode of hydraulic presses and die-casting machines to achieve a fully automated production process.

This integrated production method significantly improves the efficiency of the production line. In addition, simulation experiments based on SolidWorks and RobotStudio show that the robot pick-up robot can efficiently complete the work program, with fast response speed and high positioning accuracy, further improving the overall efficiency of the production line.

Reduce labor costs and improve the working environment

- Automated die-casting reduces the need for manual operation and reduces the labor intensity of workers.

- For example, replacing manual operation with automated equipment can reduce the exposure time of workers in dangerous areas and reduce the impact of high temperature, high noise and pollution.

- In addition, the automation system can also reduce the number of workers required per shift, thereby saving labor costs.

Improve product quality and consistency

- The application of robots in the die-casting process can achieve higher precision and consistency.

- For example, the die-casting die dressing robot system controlled by the CAD/CAM system can generate accurate tool paths according to surface conditions and adjust grinding conditions to improve product quality.

- In addition, the automation system can also monitor key parameters (such as mold temperature, humidity and liquid viscosity) in real time to ensure the stability and consistency of the die-casting process.

Haichen always use automated die-casting with robots during die casting process. Like below photo show, aluminium frying pan die casting process uses automated robot to pick the finished pan from the mould.

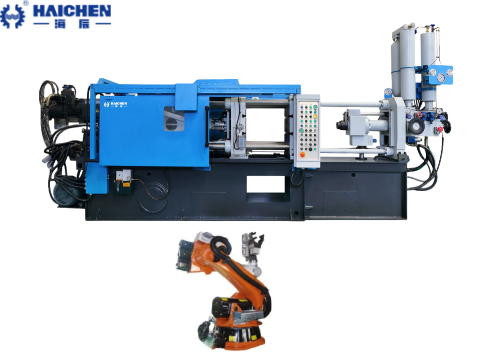

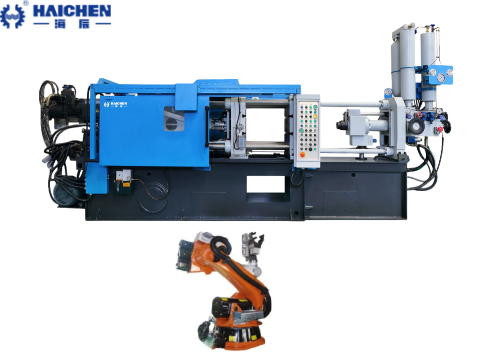

The features of Haichen autmated die casting machine robots include a synchronized six-axis or linear robot for precise part extraction, trimming, and spray operations, all governed by a centralized control system. This setup ensures impeccable timing, maximizes machine uptime, and achieves consistent cycle times. The automation guarantees gentle handling of delicate castings, drastically reduces manual labor, and enhances workplace safety by removing operators from hazardous areas. Ultimately, Haichen’s robotic integration delivers superior efficiency, repeatability, and a significant boost in overall productivity for high-volume manufacturing.

Enhance flexibility and adaptability

- Automated die-casting systems can achieve flexible production adjustments through modular design and intelligent programming.

- For example, the cutting system based on Agent technology can achieve preliminary intelligent processing through offline programming and intelligent sensing technology to adapt to the needs of complex tasks.

- In addition, the automation system can quickly adjust process parameters according to production needs to improve production flexibility.

Enhance safety

- The application of robotics reduces the direct involvement of operators in dangerous areas and reduces the risk of industrial accidents.

- For example, in continuous casting, the application of robotics not only improves safety, but also reduces the exposure time of operators in high temperature environments.

Reduce mold damage

The automation system can monitor the mold status in real time and warn of abnormal conditions in time, thereby reducing mold damage caused by improper operation or environmental factors.

Technical Challenges and Future Development

- Adaptability to complex tasks

- Energy consumption

- System integration

Although the application of robots in die casting has made significant progress, there are still some challenges:

Adaptability to complex tasks

Some complex die casting tasks require higher flexibility and adaptability, such as handling molds of different shapes and sizes.

Energy consumption

Although robots have improved production efficiency, their operation still consumes a lot of electricity.

System integration

A fully automated die casting production line requires highly integrated control systems and software support to ensure the coordinated operation of all links.

Automated die casting with robot future outlook

With the advancement of technology, automated die casting will become more intelligent and efficient in the future:

- Collaborative robots (Cobots)

- Data analysis and optimization

- Sustainable development

Collaborative robots (Cobots)

Collaborative robots will play a greater role in the die casting field, working with human operators to complete tasks that require flexibility and precision.

Data analysis and optimization

By introducing sensors and data analysis technology, the automation system can monitor the production process in real time and optimize parameter settings.

Sustainable development

With the increase in attention to environmental protection and energy conservation, automated die casting will adopt more energy-saving technologies and materials.

The combination of automated die casting and robotics not only improves production efficiency and product quality, but also improves the working environment and reduces costs. However, to fully realize its potential, it is still necessary to overcome technical challenges and continue to promote technological innovation.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.