Robots are worked in die casting through high-precision robotic arms, specialized end effectors, and deep integration with die-casting machines.

Robots are widely used in die casting due to their ability to handle high temperatures, hazardous materials, and repetitive tasks with precision and consistency. Here’s how robots work in various stages of the die casting process:

- Preparation of Molds

- Automatic Handling of Materials

- Trimming and Deburring

- Inspection and Quality Control

The use of robots in the die casting process not only improves productivity and product quality, but also significantly improves the safety and comfort of the working environment.

Preparation of Molds

- Application of Lubricant

- Regulating the Temperature of the Die

Application of Lubricant

Robots have the ability to apply mold release agents or lubricants to the die cavity. This achieves more uniform application, which is important for adequate release and surface quality of the casting, for example Yaskawa MH24 can have sprayers mounted on it to lubricate the mold cavities uniformly.

Regulating the Temperature of the Die

Some robots have been customized to fit with die temperature control or monitoring sensors to maintain optimal casting conditions.

Automatic Handling of Materials

Manual handling will include the following:

- Automated pouring of molten metal

- Working with inserted molds

- Post-cleaning and post-cooling operations

Robots have developed the capability of performing an extensive range of material handling functions in the die casting operations such as:

Automated pouring of molten metal

The robot is capable of steady pouring of molten metal into the mold without any sudden movements that are often witnessed in manual operations.

Working with inserted molds

Robots are capable of rapidly and accurately inserting and removing molds within a die casting machine which reduces cycle time and improves efficiency.

Post-cleaning and post-cooling operations

The robot achieves the removal of solidified castings out of the mold and transfers the castings to the cooling stations or to other processing sections that are queued to work on the castings.

Trimming and Deburring

Robots can trim excess material, such as sprues, runners, and flash, with high precision. This ensures that the final part meets the required specifications.

Inspection and Quality Control

Robots can also be used for non-destructive quality inspections, such as detecting defects on the surface of a casting via optical scanners or specific sensors. This automated inspection not only improves inspection efficiency, but also reduces human error and ensures consistent product quality.

What is a die-casting robot?

The Die-Casting Robot represents a class of industrial robots whose focus is on the die-casting of metal. Their primary purpose is to automate die-casting to the extent it is possible so that production efficiency is maximum, costs are minimum, and quality is consistent. They are extensively used in the metal die-casting production lines in the automotive, electronics, home appliances, etc. Industries.

Benefits of using a die-casting robot

Using die casting robots has numerous advantages especially in productivity margin, product quality, safety and cost control.

- Improved productivity and stability

- Reduction of labor costs with improvement of the working environment

- Enhanced Security

Improved productivity and stability

Die casting robots can work round the clock, only stopping for equipment maintenance and repair. Such uninterrupted working schedule considerably increases productivity. Moreover, uniterruptibility of robot’s operations leads to more standard and repeatable production processes which greatly diminish the probability of errors.

Reduction of labor costs with improvement of the working environment

As costs of labor increase, the level of automation that is economically viable also increases. For instance, in China, although die-casting workers are paid higher salaries, the payback period for robots is typically within a year.

Enhanced Security

Die casting environments often involve hazards such as high temperatures, dust and noise, and robots can protect workers from injury by replacing manual labor for high-risk tasks such as removing hot castings from molds.

In addition, robots can reduce the amount of time workers are exposed to high temperatures, reducing the risk of occupational disease.

Key considerations when choosing a die-casting robot

When choosing a die-casting robot, several key considerations must be taken into account to ensure the robot meets the specific needs of your production process. Here are the main factors to consider:

- Selection of robot type

- Production requirements and machine performance

- Work environment and mission requirements

- Speed and Cycle Time

Selection of robot type

There are several types of die casting robots, including flexible articulated robots such as SCARA robots and six-axis robots.

Articulated robots are suitable for fast, precise movements, while six-axis robots are suitable for complex tasks such as disassembly and assembly of parts. Choosing the right type of robot for your specific needs is key.

Production requirements and machine performance

Production size and product complexity directly affect machine selection. For example, a high-volume production line may require faster cycle times and greater load capacity, while the production of complex parts requires greater precision and flexibility.

Work environment and mission requirements

Before selecting a robot, it is important to identify the specific tasks it will perform in a die casting line, such as whether it will be handling hot metal, cleaning burrs or performing part handling. This helps determine the robot’s load capacity, its operating range, and whether special features are needed.

Speed and Cycle Time

The robot’s speed should match the cycle time of the die-casting process to avoid bottlenecks. Robotic simulation can help validate cycle times and ensure the robot can keep up with production rates.

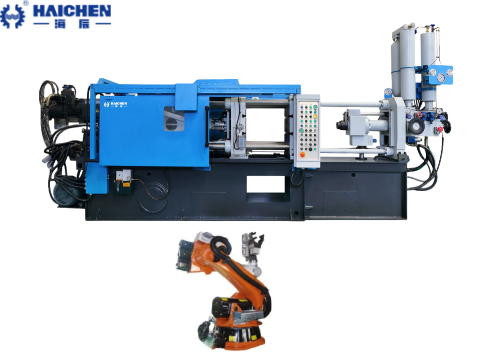

Die casting machine supplier: Haichen Machinery

Haichen is a die casting machine factory located in Ningbo, China, mainly supplying cold chamber die casting machine and hot chamber die casting machine. Besides machines, we also supply die casting auxiliary equipments and spear parts, including robots, conveyor, spray systems, mold temperature controllers, and industrial robots.

If there is any demand, welcome to consult us.